Herbicide mixture preparation

A herbicide and preparation technology, applied in the field of pesticides, can solve the problems of low content of powder products, unenvironmental protection, and high dosage, and achieve the effects of stable physical properties, reduced usage, and reduced costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

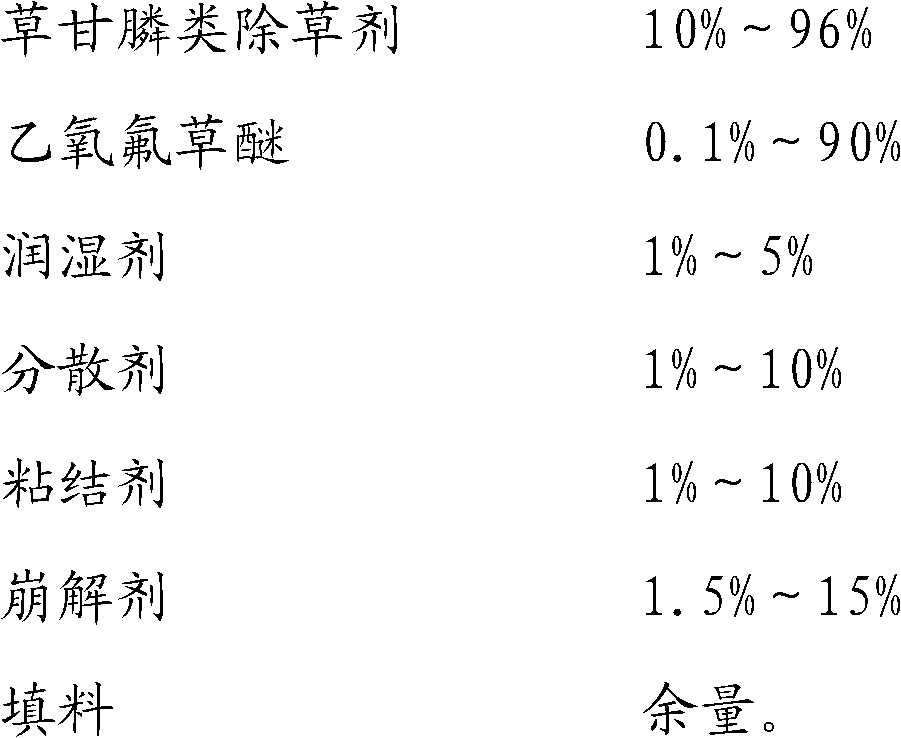

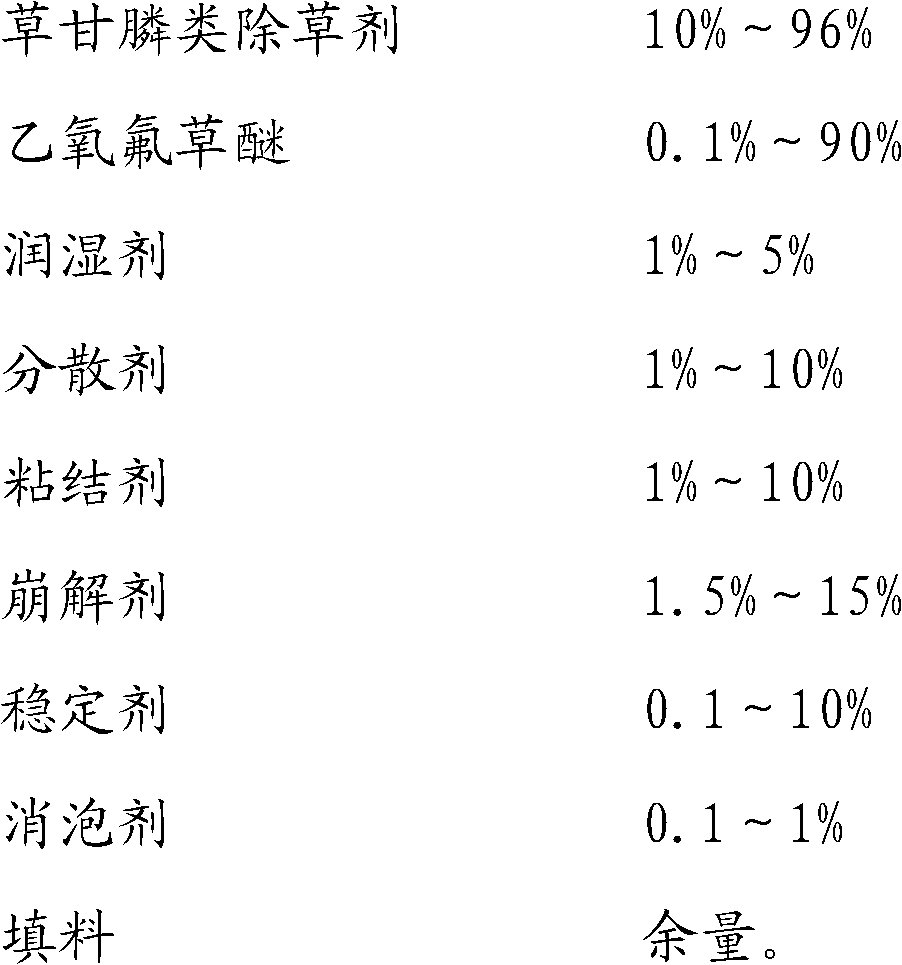

Method used

Image

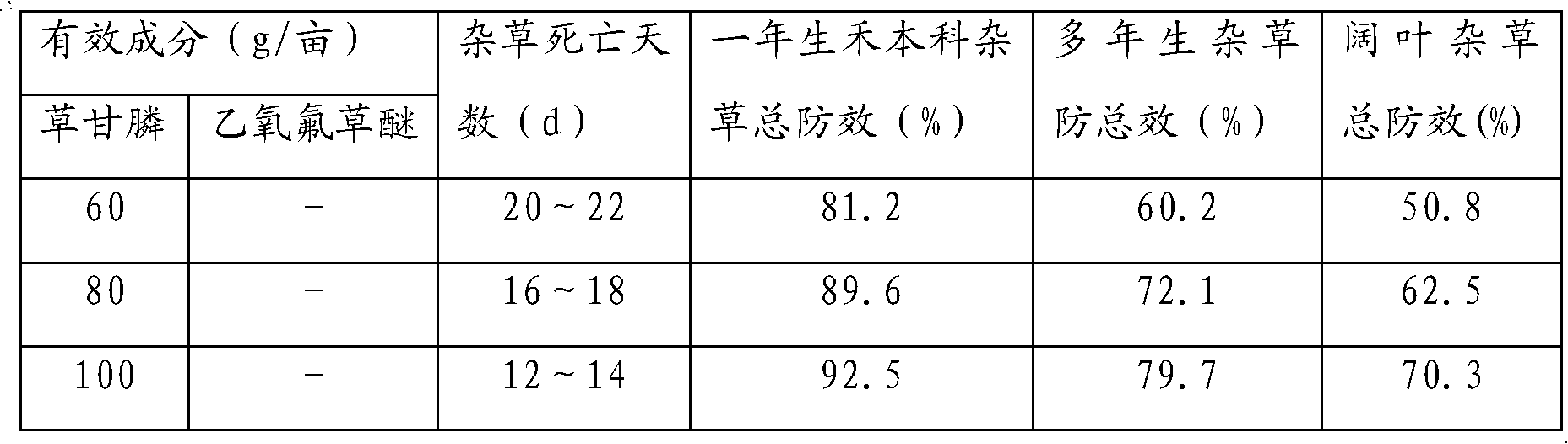

Examples

Embodiment 1

[0024] 78kg glyphosate ammonium salt technical, 2kg oxyfluorfen technical, sodium lauryl sulfate 2kg, calcium lignosulfonate 3kg, polyvinylpyrrolidone 1.5kg, triethanolamine oleate 1kg, ammonium sulfate 12.5kg , put into the mixer and mix for 30 minutes, then carry out airflow crushing, so that 90% of the particle size of the material is less than 15 microns, put it into the kneader, add an appropriate amount of water, knead for 40 minutes, put it into the extrusion granulator for granulation, and dry , After sieving, 80% ammonium glyphosate · oxyfluorfen water dispersible granules were obtained.

Embodiment 2

[0026] 5kg of the original drug of glyphosate potassium salt, 56kg of the original drug of oxyfluorfen, 3kg of alkyl naphthalene sulfonate, 6kg of polycarboxylate, 1kg of carboxymethyl cellulose, 2,6-di-tert-butyl p-methyl 0.5kg of phenol, 6kg of urea, 0.1kg of silicone defoamer, and 22.4kg of lactose were added to the mixer and mixed for 40 minutes, followed by jet milling, so that 90% of the particle size of the material was less than 10 microns, put into the kneader, and an appropriate amount of water, kneaded for 30 minutes, put into an extrusion granulator for granulation, dried, and sieved to obtain 61% glyphosate potassium salt · oxyflufen water-dispersible granules.

Embodiment 3

[0028] 80kg of the original drug of glyphosate isopropylamine salt, 3kg of the original drug of oxyfluorfen, 1.5kg of polyoxyethylene ether of alkylphenol formaldehyde resin, 3.5kg of sodium methylene dimethyl naphthalene sulfonate, and 2kg of polyethylene glycol , 3kg of citric acid, 3kg of sodium carbonate, 0.3kg of isooctyl alcohol, and 3.7kg of bentonite were added to the mixer and mixed for 15 minutes, and then jet crushed to make 95% of the particle size of the material less than 12 microns. Put it into the kneader and knead for 60 minutes , directly put into a tablet machine for tableting, drying, and sieving to obtain 83% glyphosate isopropylamine salt · oxyfluorfen tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com