Fuzzy sliding mode and neural network based composite control system of permanent synchronous motor

A permanent magnet synchronous motor, fuzzy sliding mode control technology, applied in the control system, vector control system, motor generator control and other directions, can solve the problems of rapidity and limited anti-interference ability, and achieve the improvement effect of traditional PID control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

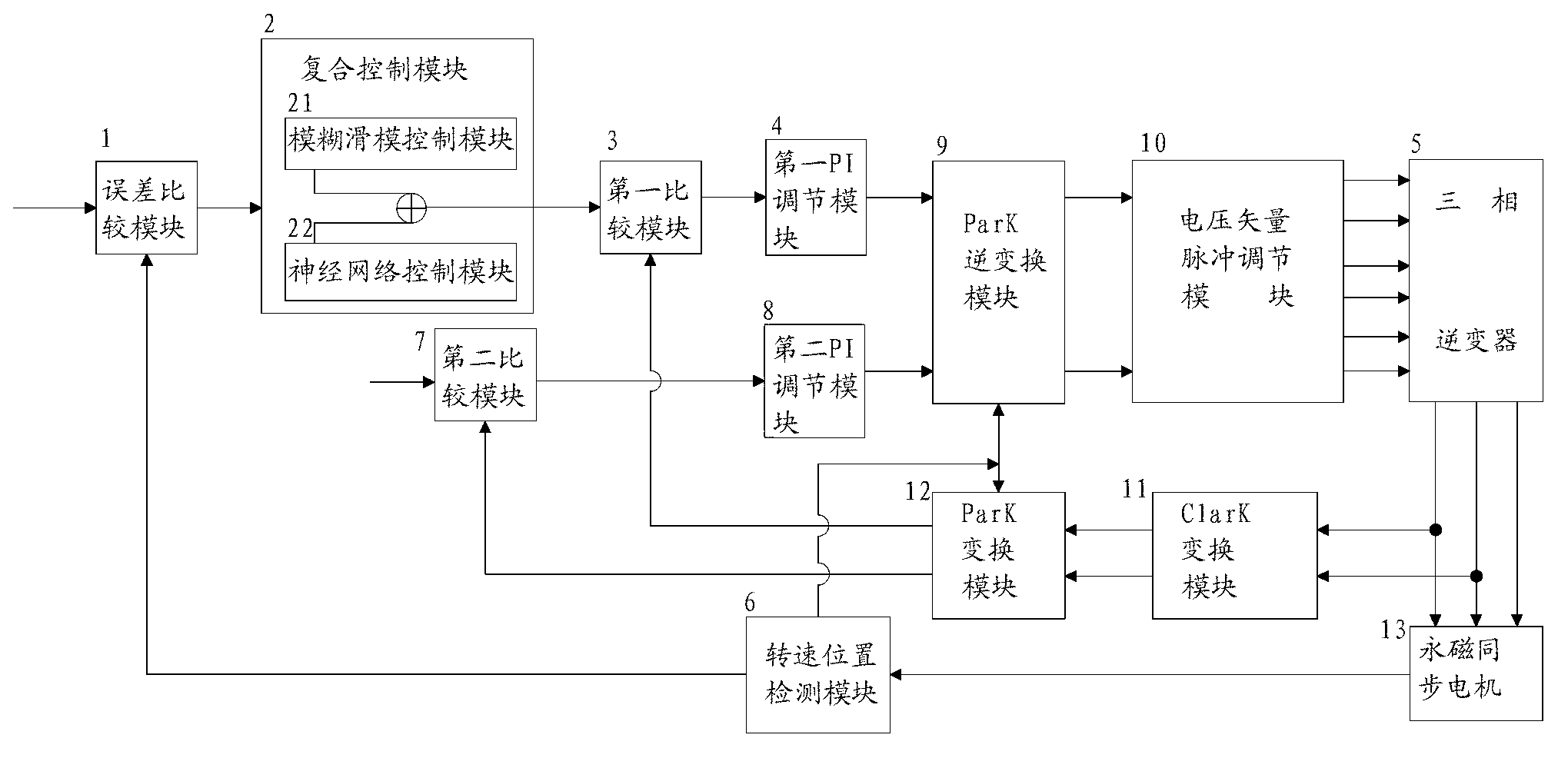

[0027] This embodiment describes a compound control system of permanent magnet synchronous motor based on fuzzy sliding mode and neural network, and its overall structure is as follows figure 1As shown, it includes a speed control outer loop and a current control inner loop. The speed control outer loop includes an error comparison module 1, a compound control module 2, a first comparison module 3, a first PI adjustment module 4, and a three-phase inverter 5 and a rotation speed position detection module 6, the current control inner loop includes a second comparison module 7, a second PI adjustment module 8, a Park inverse transformation module 9, a voltage vector pulse width modulation module 10, a Clark transformation module 11 and a Park transformation module 12. The three-way output of the three-phase inverter 5 is connected to the permanent magnet synchronous motor 13, the permanent magnet synchronous motor 13 is connected to the speed position detection module 6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com