Shell cover opening and closing force detection system for pneumatic sample-transporting shells and detection method

A detection system and projectile technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems of undetectable opening and closing force, easy loss of samples of sent projectiles, etc., to achieve reliable and convenient detection, reduce Equipment cost, effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

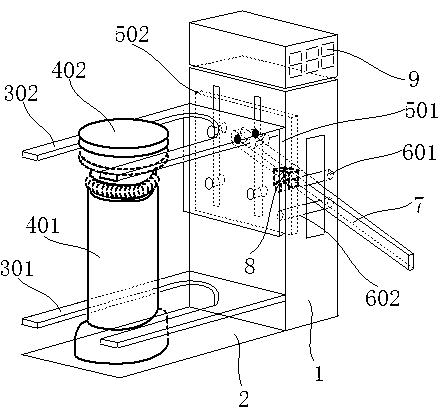

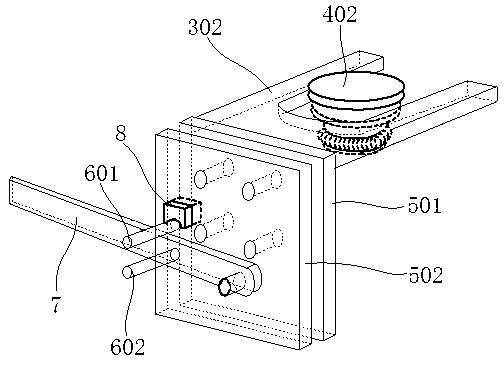

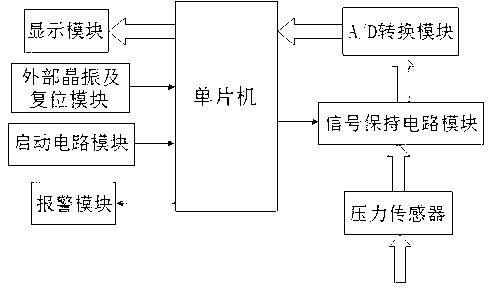

[0036] combine figure 1 and figure 2 , a shell cover opening and closing force detection system for pneumatic sample delivery shells of the present embodiment, which consists of an opening and closing device box 1, a bottom plate 2, a lower caliper 301, an upper caliper 302, an outer connecting plate 501, an inner connecting plate 502, It consists of a cover-opening force column 601, a cover-closing force column 602, a handle 7, a pressure sensor 8, a force-measuring control box 9, and the like.

[0037] The structural diagram of the shell cover opening and closing force detection system is as follows: figure 1As shown, a lower caliper 301, an upper caliper 302, and a bottom plate 2 are arranged outside the same side wall of the opening and closing device box 1 in this embodiment, and the lower caliper 301, the upper caliper 302, and the bottom plate 2 are all arranged horizontally, and the bottom plate 2. It is fixedly connected to the bottom of the opening and closing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com