Liquid hydrostatic bearing capable of realizing oil distribution from end surface

A hydrostatic bearing and liquid technology, applied in the field of bearing components, can solve problems such as inconvenient installation, disassembly and cleaning, difficult oil pressure consistency, increased cost, etc., to achieve convenient disassembly and cleaning and later maintenance, ensure consistency, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

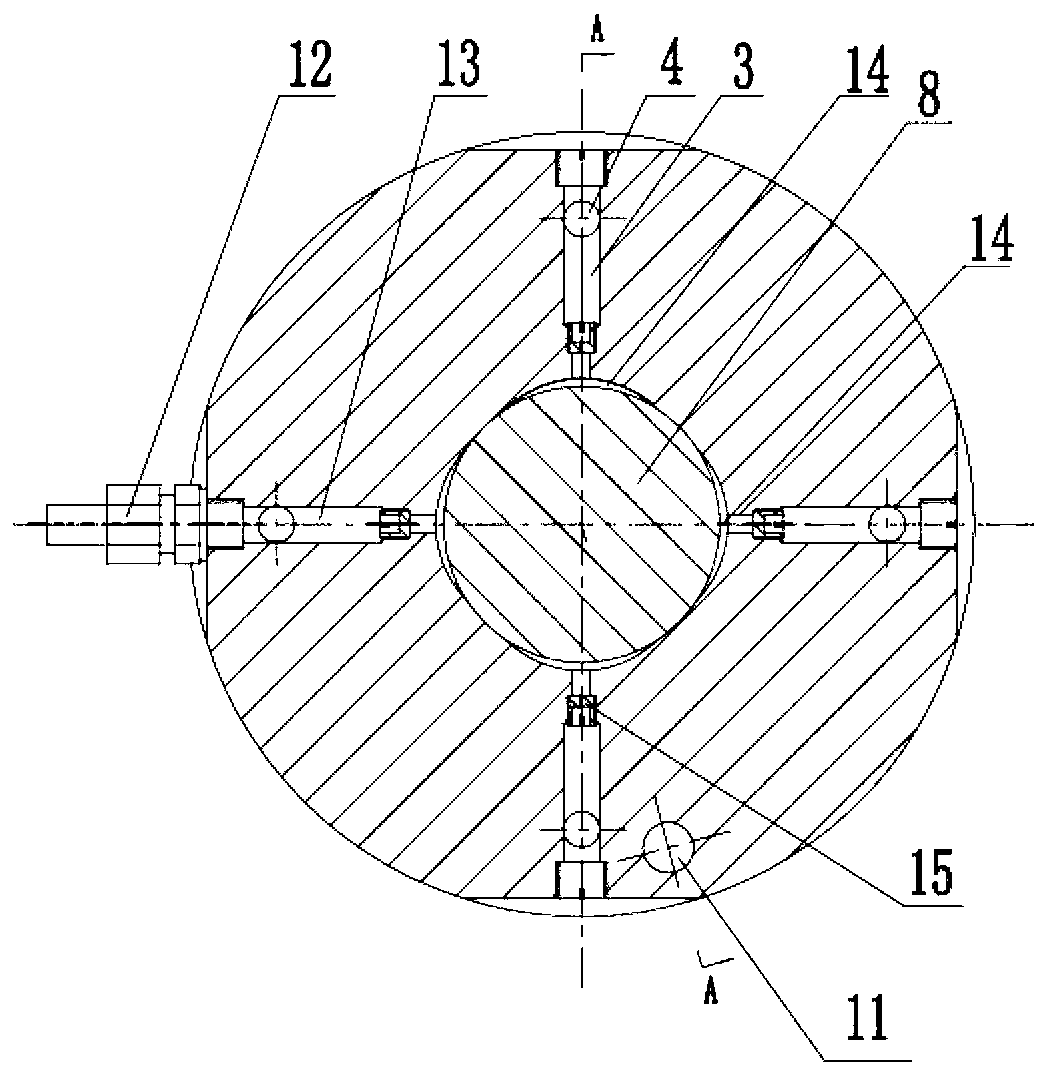

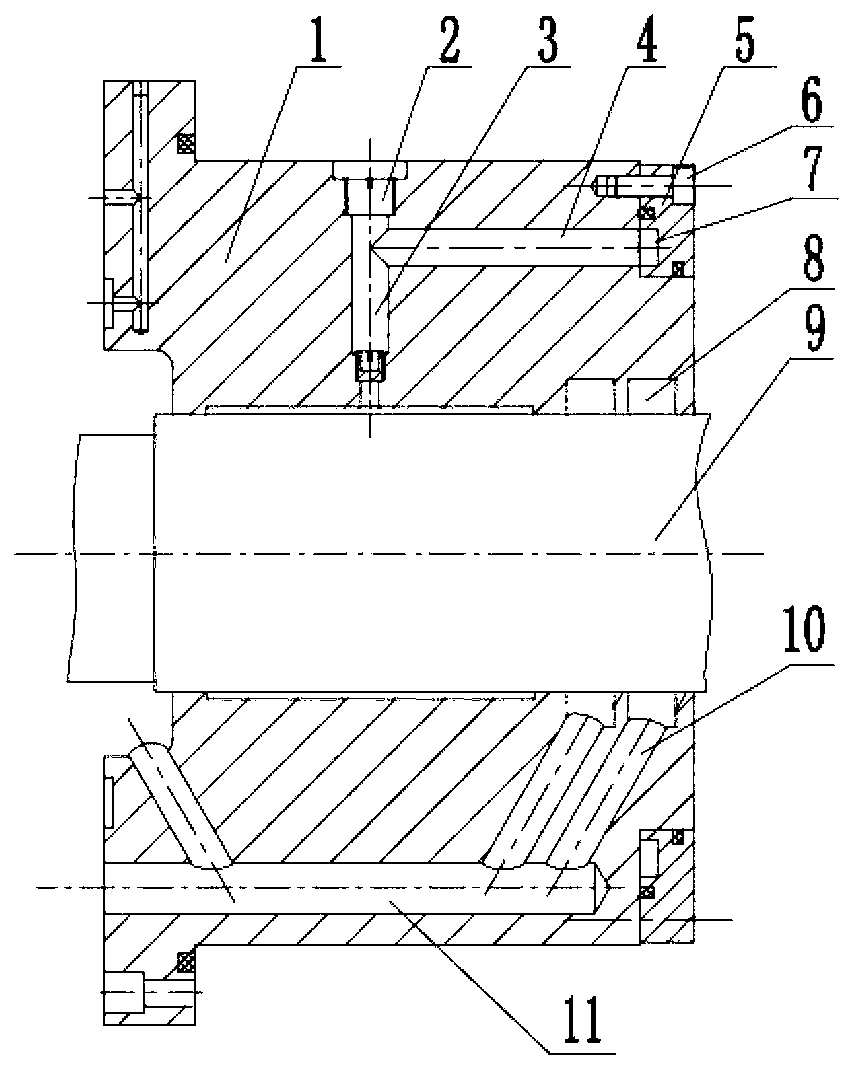

[0031] figure 1 is a schematic diagram of the main structure of the hydrostatic bearing according to the present invention. like figure 1 As shown in , the hydrostatic bearing according to the present invention mainly includes a bearing body 1, a plurality of bearing oil chambers 14 located on the inner surface of the bearing body 1 and evenly distributed along the bearing circumferential direction (in figure 1 shown as 4, and can also be designed as other numbers, such as 3, 6, etc.), the oil inlet piping system for delivering hydraulic oil to each bearing oil chamber 14, and for sending the use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com