High-pressure water seal dual-power auger stem

An auger rod, dual power technology, applied in drill pipe, drill pipe, earthwork drilling, etc., can solve the problem of difficult to meet the requirements of high-efficiency deep hole drilling in soft coal seams, with low resistance of the outer flat drill pipe, and fluid slag discharge. Failure and other problems, to achieve the effect of simple structure, good slag discharge effect and high operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

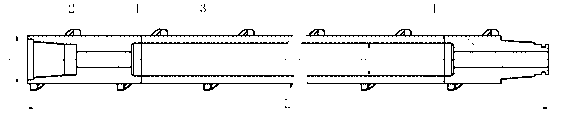

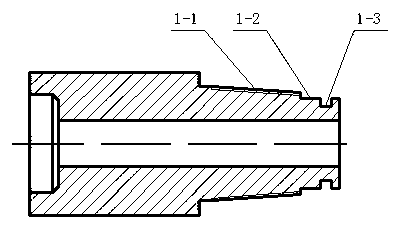

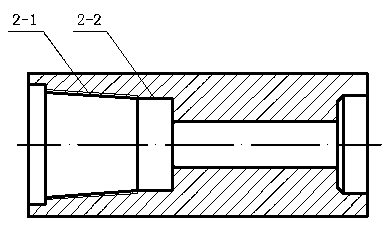

[0026] see figure 1 , the outer diameter of the dual power auger drill pipe φ 1 50mm, rod inner diameter φ 2 It is 34mm, and the length L is 1000mm. It is composed of a male joint 1, a rod body 3, a female joint 2 and a helical blade 4 connected in sequence, and is welded into one body by friction welding. The male joint 1 is connected to the next drill pipe female joint 2 The connection end of the drill pipe joint 1 is composed of the straight shaft section 1-2 and the external taper thread 1-1 in turn; Threaded 2-1 connection composition. The thread type of the external tapered thread 1-1 of the male joint and the internal tapered thread 2-1 of the female joint is a positive spiral tapered thread, the taper is 1:8, and the pitch is 5.08mm (5 teeth per inch). The straight shaft section 1-2 of the male joint is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com