Method for batch preparation of pure phase AlON transparent ceramic powder body

A transparent ceramic and pure-phase technology, applied in the field of batch preparation of pure-phase AlON transparent ceramic powder, can solve the problems of unexplained performance of transparent ceramics, oxidation of AlON powder, unfavorable industrial production, etc. Activated carbon, good reactivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] ① Mixing: Al with an average particle size of 80nm 2 o 3 The mixed powder of analytically pure activated carbon particles is mixed with silicon nitride as the ball milling medium and dehydrated alcohol as the dispersion medium at a speed of 170r / min for 12h, wherein the activated carbon accounts for 5.6wt.% of the total mass of raw materials, and the quality of dehydrated alcohol is 4 times the quality of the raw material, the specific surface area is 253m 2 / g of mixed powder slurry.

[0062] ②Drying: Dry the slurry obtained in step ① on an electric heating plate at 140°C for 1.2h in the air, and pass through a 50-mesh sieve to obtain Al 2 o 3 Mix powder with activated carbon;

[0063] ③Fabrication: Put the mixed powder in a graphite crucible with a radius of 85mm, the powder filling height is 43mm, and the air holes with a diameter of 1.5mm and a spacing of 10mm are preset in the powder;

[0064] ④Pre-vacuumize the sintering furnace: place the graphite crucible i...

Embodiment 2

[0069] Other steps are identical with embodiment 1, difference is:

[0070] Step 1. Mixing: Al with an average particle size of 80nm 2 o 3 The mixed powder of analytically pure activated carbon particles was mixed with silicon nitride as the ball milling medium and dehydrated alcohol as the dispersion medium at a speed of 170r / min for 2h, wherein the activated carbon accounted for 5.6wt.% of the total mass of raw materials, and the quality of dehydrated alcohol was 4 times the quality of the raw material, the specific surface area is 195m 2 / g of mixed powder slurry.

[0071] ②Drying: Dry the slurry obtained in step ① on an electric heating plate at 140°C for 1.2h in the air, and pass through a 50-mesh sieve to obtain Al 2 o 3 Mix powder with activated carbon;

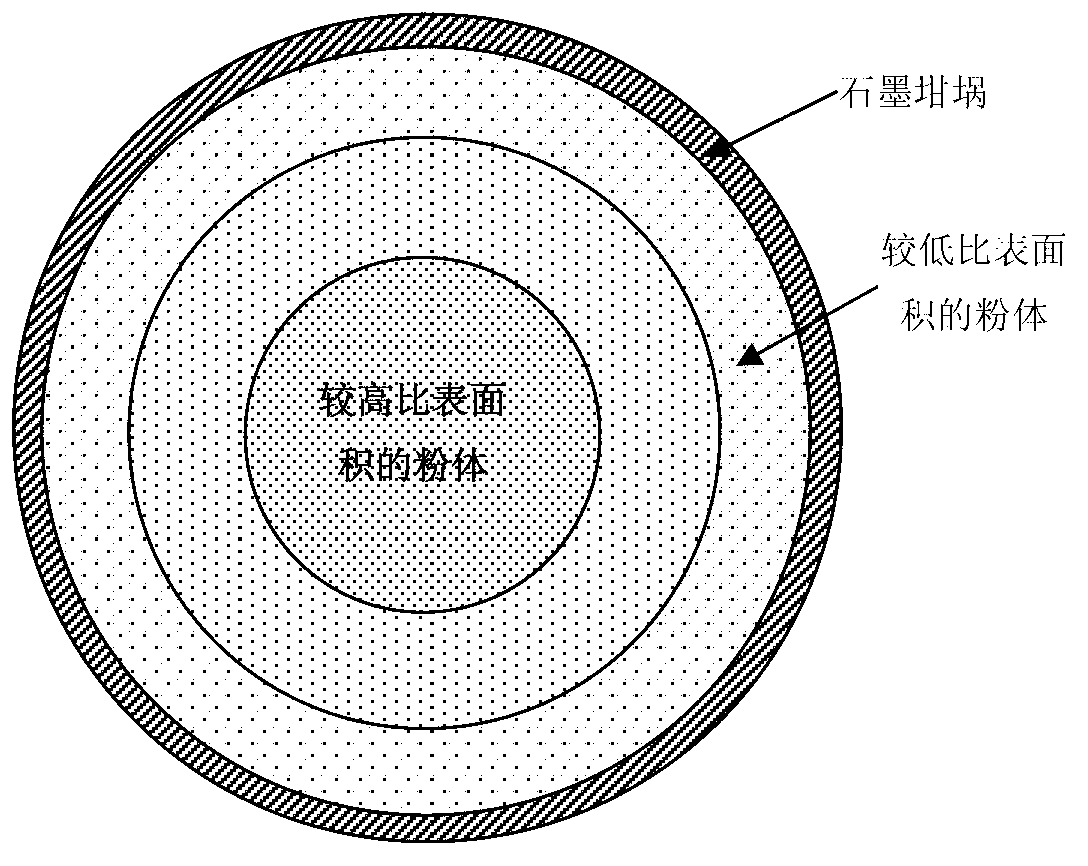

[0072] ③Fabrication: Put the mixed powder in a graphite crucible with a radius of 120mm, the powder filling height is 43mm, and the above-mentioned 195m 2 The mixed powder of / g is placed in the region with a rad...

Embodiment 3

[0075] Other steps are identical with embodiment 1, difference is:

[0076] Step 1. Mixing: Al with an average particle size of 80nm 2 o 3 The mixed powder of analytically pure activated carbon particles was mixed with silicon nitride as the ball milling medium and dehydrated alcohol as the dispersion medium at a speed of 160r / min for 24h, wherein the activated carbon accounted for 5.6wt.% of the total mass of raw materials, and the quality of dehydrated alcohol was 4 times the quality of the raw material, the specific surface area is 177m 2 / g of mixed powder slurry.

[0077] ③Fabrication: Put the mixed powder in a graphite crucible with a radius of 150mm, the powder filling height is 43mm, and the above-mentioned 177m 2 The mixed powder of / g is distributed in the area that the radius is greater than 120mm, and embodiment 2 steps 2. gained 195m 2 The mixed powder of / g is arranged in the area of radius 852 / g of mixed powder is placed in an area with a radius of less t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com