Concrete member mending agent, preparation method and construction method

A construction method and repairing agent technology, which are used in earth-moving drilling, construction maintenance, shaft equipment and other directions, can solve the problems of large hydration shrinkage of cement slurry, insufficient cohesion, and easy cracking, and achieve improved construction performance, The effect of reducing construction strength and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

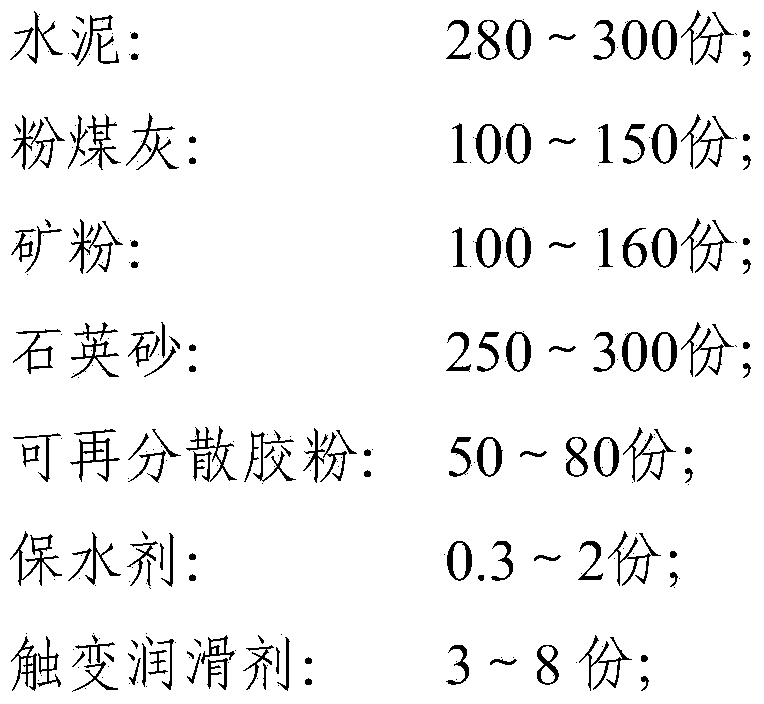

[0067] The formula of the repair agent is as follows:

[0068] P.O42.5 Portland cement: 240kg;

[0069] Grade 42.5 sulphoaluminate cement: 60kg;

[0070] Grade Ⅱ fly ash: 150kg;

[0071] S95 grade mineral powder: 100kg;

[0072] 70-120 mesh quartz sand: 280kg;

[0073] Rubber powder 8031H: 50kg;

[0074] Rubber powder 5011L: 20kg;

[0075] Cellulose ether 10007P4: 0.5kg;

[0076] Thixotropic lubricant 602: 5kg.

[0077] The preparation process is as follows: accurately weigh each raw material component of the above-mentioned weight, mix and stir evenly to obtain.

[0078] The construction process is as follows:

[0079] (1) The concrete components such as bridge piers, beam bodies, tunnels, track slabs, etc. to be treated are first cleaned with wire brush to clean the surface of the floating slurry;

[0080] (2) Sprinkle water on the surface of the concrete component to be treated until the concrete surface is saturated with water;

[0081] (3) Mix the repair agent and water in a ratio of water:...

Embodiment 2

[0094] The cement paint formula is as follows:

[0095] P.O42.5 Portland cement: 232kg;

[0096] Level 42.5 sulphoaluminate cement: 58kg;

[0097] Grade Ⅱ fly ash: 100kg;

[0098] S95 grade mineral powder: 160kg;

[0099] 70-120 mesh quartz sand: 300kg;

[0100] Rubber powder 8031H: 45kg;

[0101] Rubber powder 5011L: 20kg;

[0102] Cellulose ether 10007P4: 1kg;

[0103] Thixotropic lubricant 602: 7kg.

[0104] The preparation process is as follows: accurately weigh each raw material component of the above-mentioned weight, mix and stir evenly to obtain.

[0105] The construction process is as follows:

[0106] (1) The concrete components such as bridge piers, beam bodies, tunnels, track slabs, etc. to be treated are first cleaned with wire brush to clean the surface of the floating slurry;

[0107] (2) Sprinkle water on the surface of the concrete member to be treated until the surface is saturated with water;

[0108] (3) Apply the dry powder of the repair agent to the surface of the component...

Embodiment 3

[0117] The formula of the repair agent is as follows:

[0118] P.O42.5 Portland cement: 260kg;

[0119] Grade 42.5 sulphoaluminate cement: 75kg;

[0120] Grade Ⅱ fly ash: 90kg;

[0121] S95 grade mineral powder: 170kg;

[0122] 70-120 mesh quartz sand: 260kg;

[0123] Rubber powder 8031H: 45kg;

[0124] Rubber powder 5011L: 25kg;

[0125] Cellulose ether 10007P4: 1.3kg;

[0126] Thixotropic lubricant 602: 9kg.

[0127] The preparation method and construction method are the same as in Example 1.

[0128] The performance test after construction and treatment according to the aforementioned construction method is as follows:

[0129] (1) The appearance color is basically the same as the base color of the concrete member;

[0130] (2) Low water absorption, the 5 hours water absorption of the Caston tube is 0.7ml;

[0131] (3) Scrub resistance, can withstand 20,000 scrubs without showing the bottom;

[0132] (4) No obvious efflorescence phenomenon;

[0133] (5) The tensile bonding strength is high, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com