Shipment method combining large constructional element rolling and floating crane

A roll-on and component technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of difficulty in loading, high cost, and singleness, and achieve the effects of reducing construction costs, ensuring safe loading, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1 A ship loading method combining roll-off and floating cranes for large components, the steps are as follows:

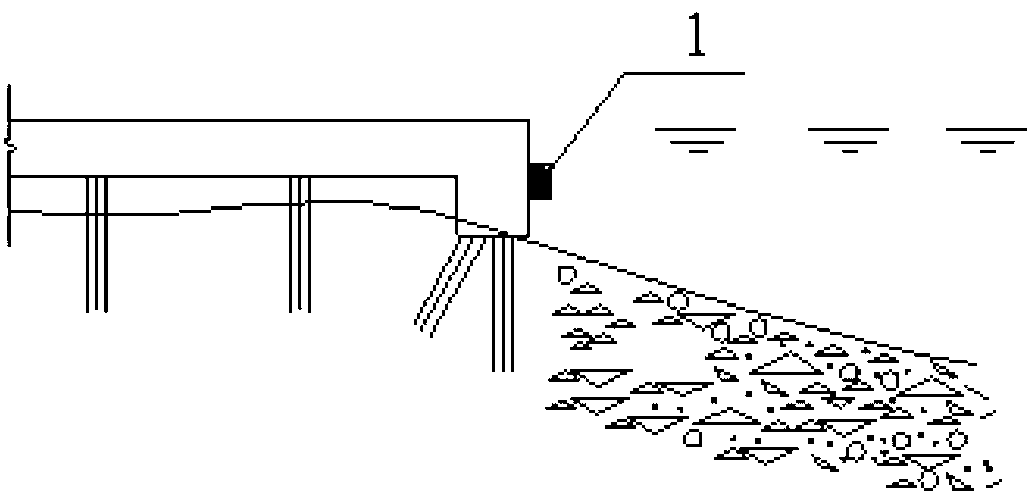

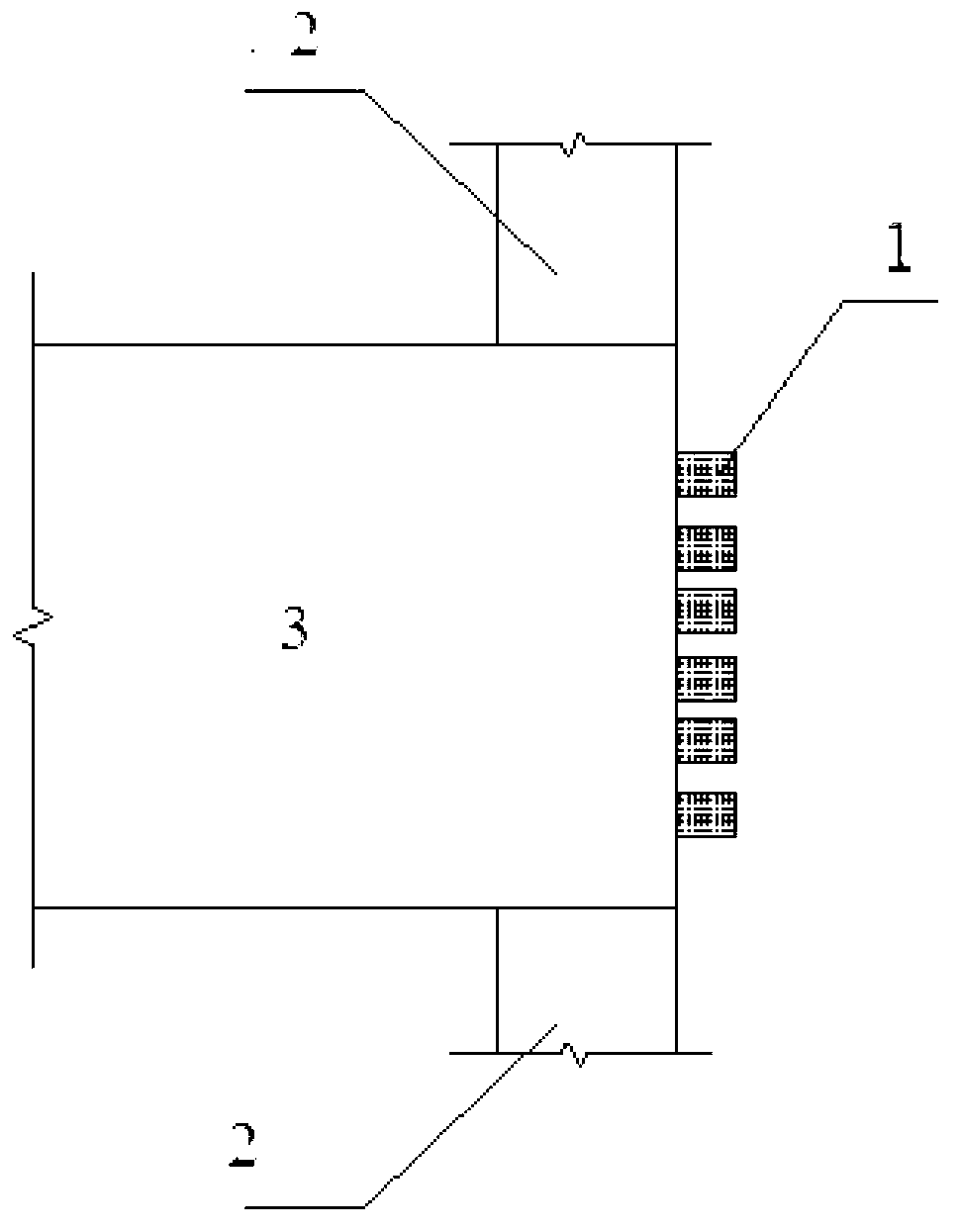

[0014] (1) Shipping preparation: dock the special girder ship on wharf 3, on which pier 3 is overlapped with trestle 2, set up pier 1 in front of wharf 3, and place the stern on pier 1 in front of wharf 3; Components are transported to wharf 3 with two large flatbed trucks, and inspected before shipment;

[0015] (2) Ro-Ro ships and floating cranes are in place: choose the appropriate tide level. When the ship is at a tide level of 2m, the deck is flush with the wharf; The flatbed truck boarded and disembarked smoothly;

[0016] Anchor positioning according to the pre-designed position; along the transverse direction of the coastline, two parallel lap platforms are arranged on the special beam carrier, and two rows of parallel tracks are laid between the lap platforms;

[0017] (3) Component ro-ro boarding: the special-purpose large flatbed truck...

Embodiment 2

[0019] Embodiment 2 A method for combining large components with ro-ro and floating cranes, the steps are as follows:

[0020] (1) Shipping preparation: dock the special girder ship on wharf 3, on which pier 3 is overlapped with trestle 2, set up pier 1 in front of wharf 3, and place the stern on pier 1 in front of wharf 3; Components are transported to wharf 3 with two large flatbed trucks, and inspected before shipment;

[0021] (2) Ro-Ro ships and floating cranes are in place: choose the appropriate tide level. When the ship is at a tide level of 3m, the deck is flush with the wharf; The flatbed truck boarded and disembarked smoothly;

[0022] Anchor positioning according to the pre-designed position; along the transverse direction of the coastline, two parallel lap platforms are arranged on the special beam carrier, and two rows of parallel tracks are laid between the lap platforms;

[0023] (3) Component ro-ro boarding: the special-purpose large flatbed truck loaded wit...

Embodiment 3

[0025] Embodiment 3 A ship loading method combining roll-off and floating cranes for large components, the steps are as follows:

[0026] (1) Shipping preparation: dock the special girder ship on wharf 3, on which pier 3 is overlapped with trestle 2, set up pier 1 in front of wharf 3, and place the stern on pier 1 in front of wharf 3; Components are transported to wharf 3 with two large flatbed trucks, and inspected before shipment;

[0027] (2) Ro-Ro ships and floating cranes in place: choose the appropriate tide level. When the ship is at a tide level of 2.63m, the deck is flush with the wharf; The large flatbed truck boarded and disembarked smoothly;

[0028] Anchor positioning according to the pre-designed position; along the transverse direction of the coastline, two parallel lap platforms are arranged on the special beam carrier, and two rows of parallel tracks are laid between the lap platforms;

[0029] (3) Component ro-ro boarding: the special-purpose large flatbed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com