Beverage bottle for storing solute

A beverage bottle and solute technology, which is applied in the field of beverage bottles, can solve the problems of thick connecting edges of sealing films, reduction of beverage substances, and resource consumption, etc., and achieves the effects of good film cutting effect, fast release of solute, and fast falling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

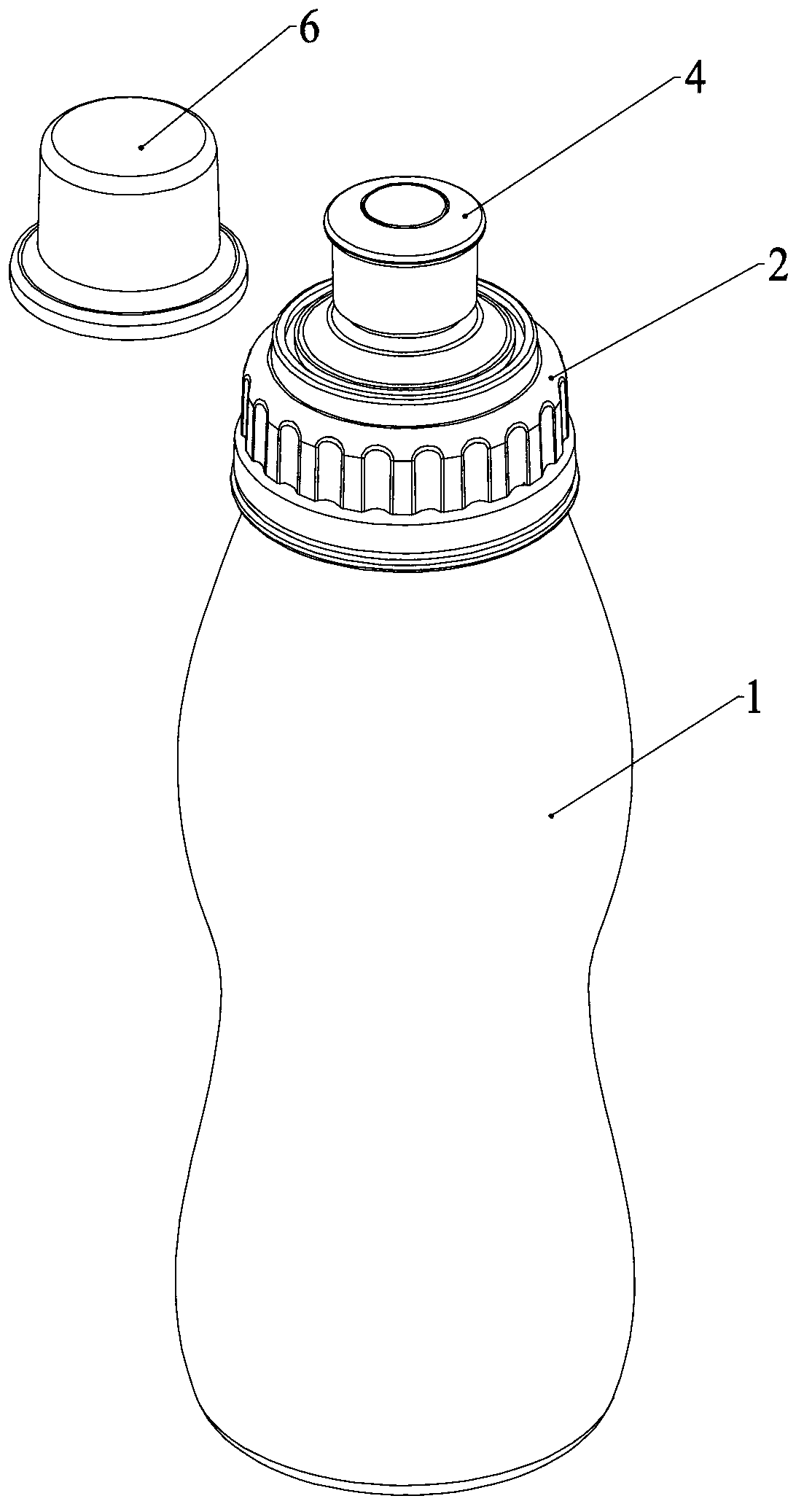

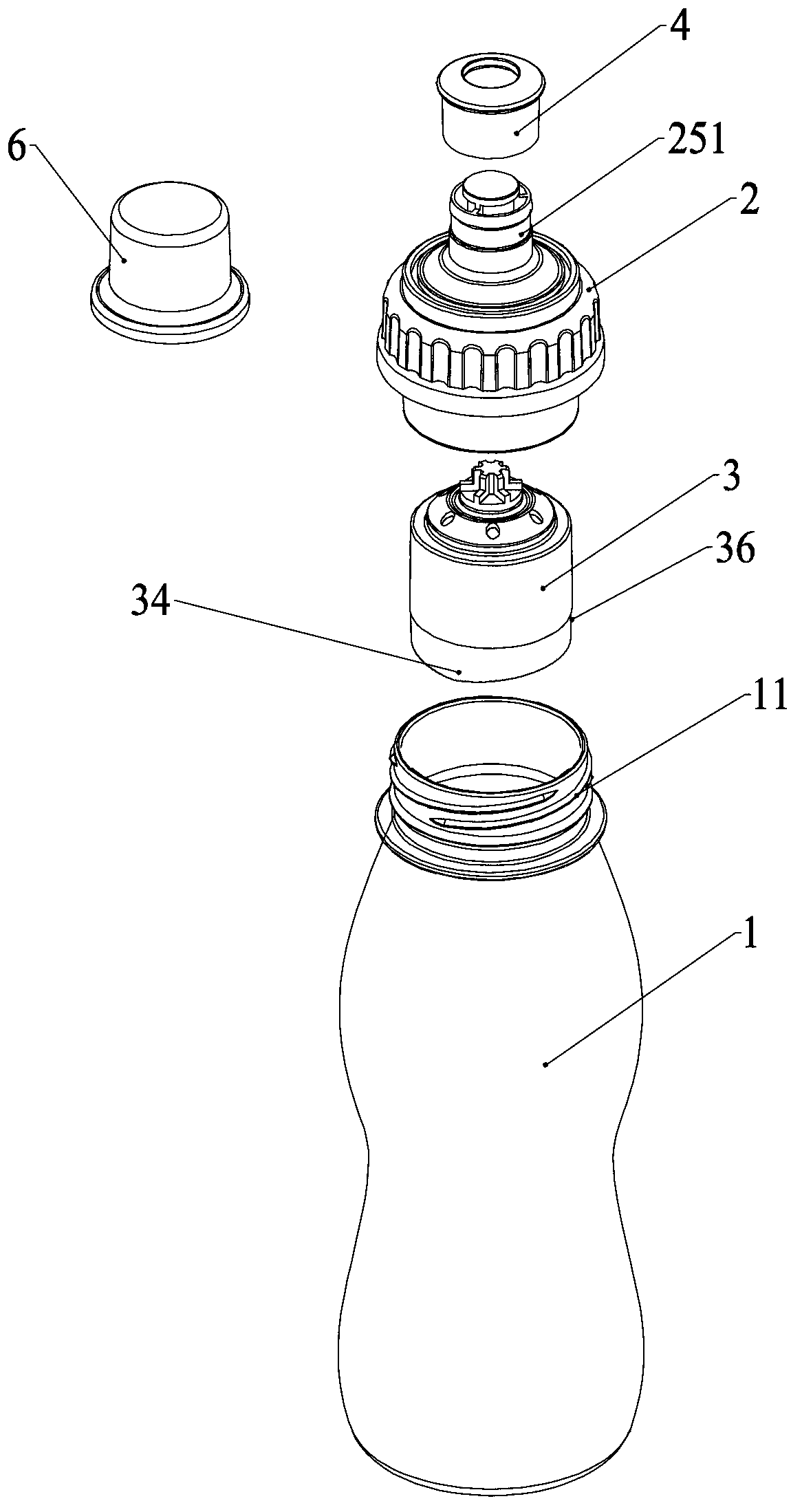

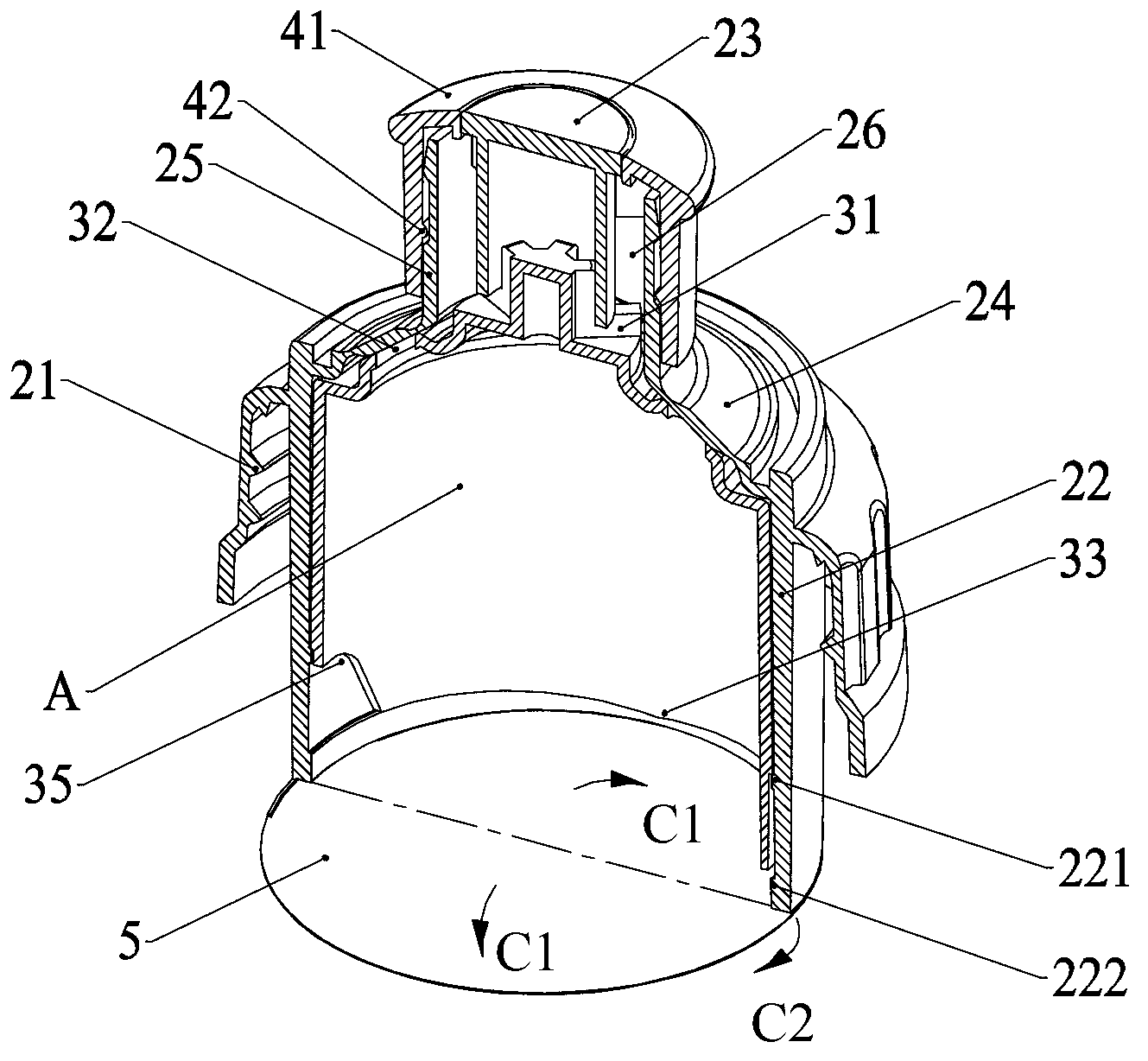

[0025] refer to Figure 1 to Figure 8 , the present embodiment is a beverage bottle with storage solute, including a bottle body 1 and a bottle cap, the bottle cap includes a bottle cap main body 2, a cut film inner cylinder 3 and a drinking pump 4; the bottle cap main body has a tightening part 21, Inner tube part 22, pressing part 23, deformable part 24 and water outlet tube part 25, the connecting end of tightening part and inner tube part are connected with water outlet tube part through bendable deformation part; The bottleneck 11 of the bottle body is screwed and connected; the cylinder body of the pressing part of the bottle cap body is fixedly connected with the water outlet cylinder part of the bottle cap body through ribs 26; The support step 36 of the cylinder is buckled on the inner convex rib 221 of the inner cylinder to prevent the beverage bottle with stored solute from breaking the membrane of the inner cylinder due to vibration before use, such as during trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com