Gluing process used for gluing of metal

A bonding metal and bonding technology, applied in the direction of coating, etc., can solve the problems of long time, not being able to meet the production application, not being able to be put into use soon, and achieve the effect of good connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

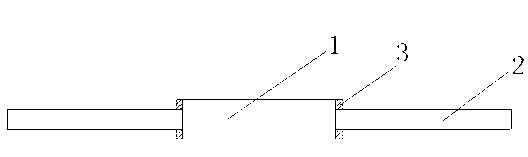

[0014] Below in conjunction with accompanying drawing, describe in further detail:

[0015] Such as figure 1 Shown, be a kind of insulating gauge pull rod that is used on the railway track, promptly adopt the bonding process of the metal described in the present invention, concrete technological process is: 1, straighten the insulating gauge pull rod, then draw the pull rod from from Put the round tube 1 at both ends and place it on the injection molding machine, then choose nylon 66 particles as the binder, dry it first after selection, put it into the hopper of the injection molding machine to heat and melt it after 4 hours, and form a fluid. Until it flows smoothly and evenly from the injection rod hole.

[0016] 2. According to the requirements of the railway standard and the assembly structure of the tie rod, adjust the setting of the bonded steel mold and injection molding, injection temperature and injection time (about 2 minutes) and the overall length of the rod. 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com