Cutting fluid recovery system for high-speed tool steel

A recycling system and cutting fluid technology, applied in the field of processing aid recycling, can solve the problems of mixing impurities, damage to the surface of the tool, waste of resources, etc., to increase the service life and application value, reduce production costs, and prevent deterioration and failure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be specifically introduced below in conjunction with specific embodiments.

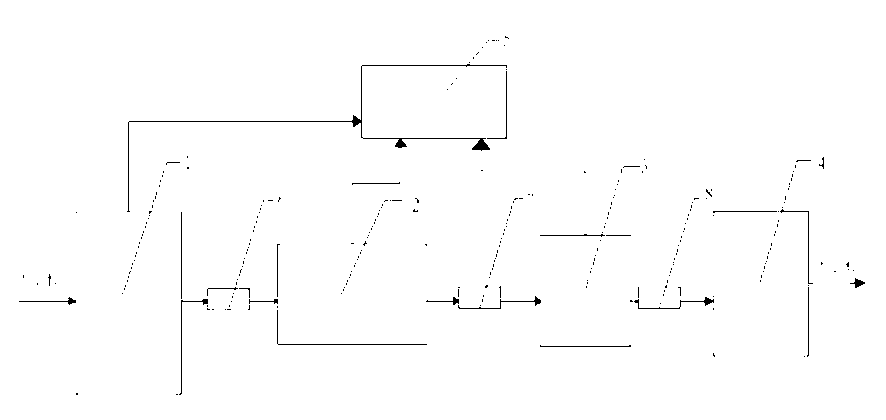

[0015] figure 1 It is a structural schematic diagram of an embodiment of the present invention.

[0016] like figure 1 Shown: The cutting fluid recovery system for cutting high-tech steel, including settling tank 1, magnetic separator 2, filtering device 3, water tank 4 and concentrated liquid storage tank 5, among which, settling tank 1, magnetic separator 2, filtering device 3 It communicates with the water tank 4 sequentially, while the concentrated liquid storage tank 5 communicates with the settling tank 1, the magnetic separator 2 and the filter device 3 at the same time, and the settling tank 1 and the water tank 4 are respectively communicated with the lathe in the grinder workshop.

[0017] Specifically: the first water pump 6 is also arranged on the pipeline between the settling tank 1 and the magnetic separator 2, the second water pump 7 is arranged betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com