Method and equipment for industrially producing clean liquid fuel by utilizing household waste or sludge press water

A technology for liquid fuel and domestic waste, applied in liquid carbon-containing fuels, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of high difficulty and high investment cost of wastewater, and achieve low cost and floor space. Small, high oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

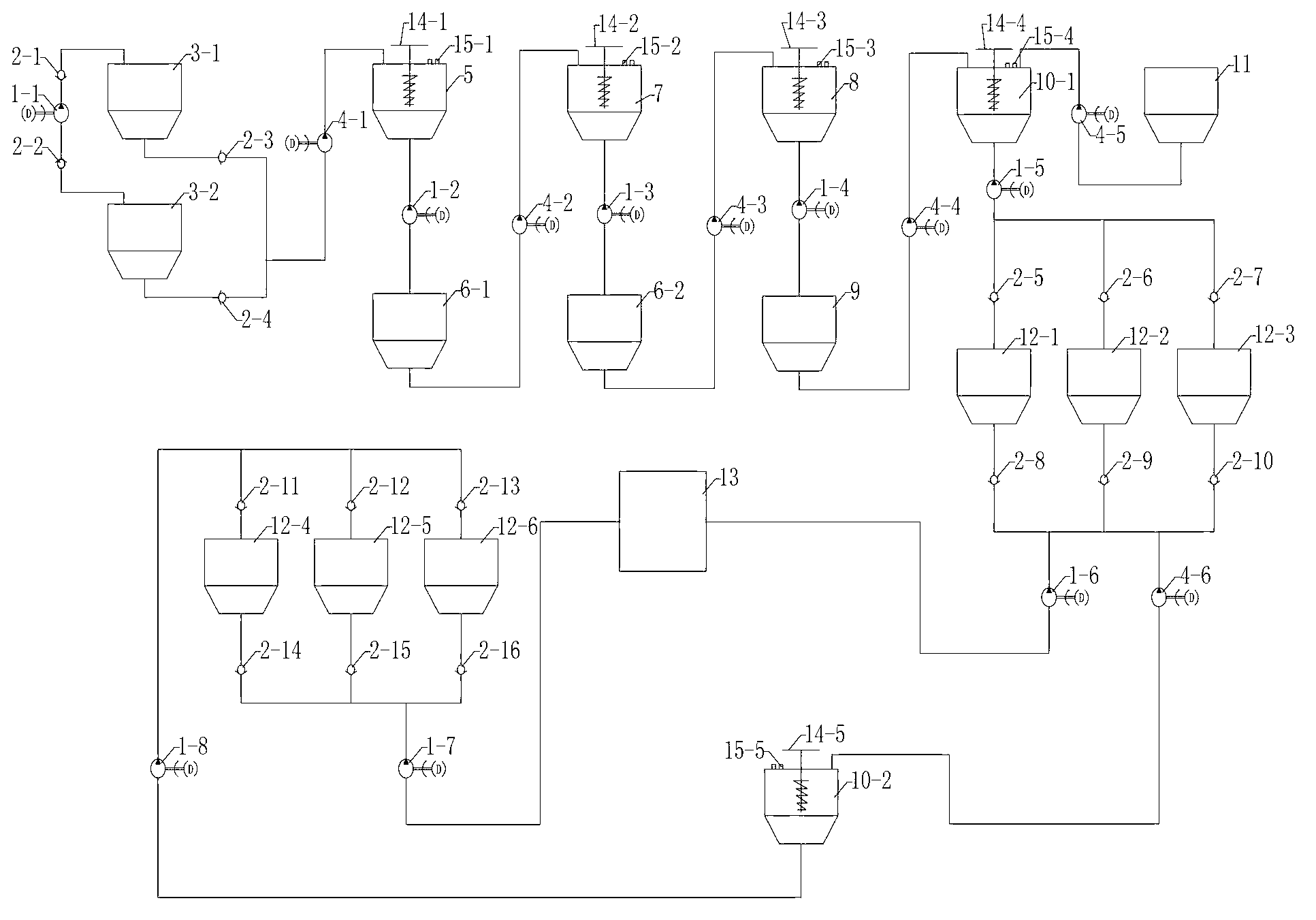

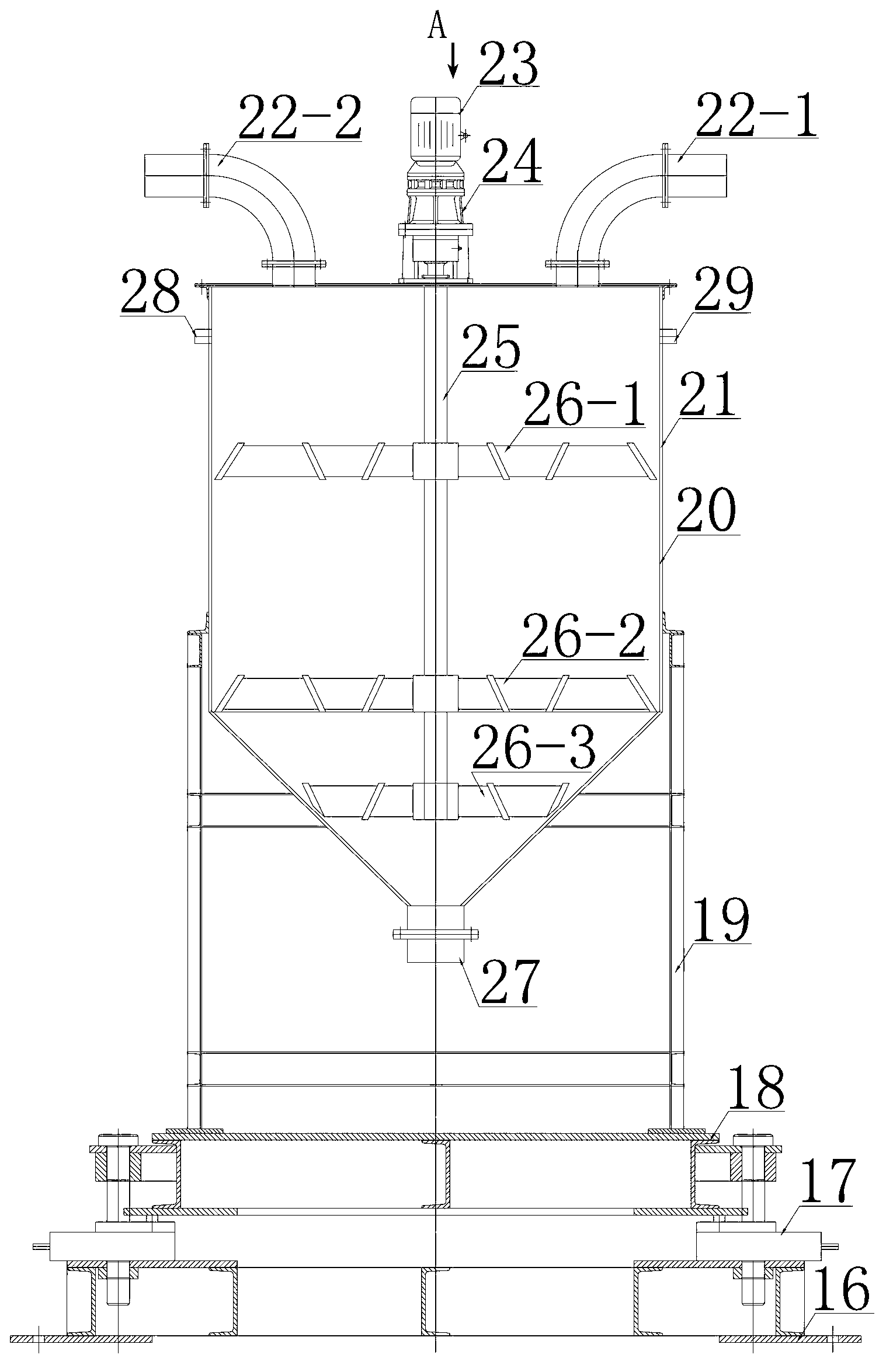

[0025] In the equipment for the industrial production of compressed water from domestic waste (leakage) and domestic sludge (water content below 85% by weight) into clean liquid fuels, direct current pumps 1-1 are used to squeeze water from domestic waste and sludge Drive into the waste liquid tanks 3-1, 3-2 respectively, there are pipeline connections between the DC pump 1-1 and the waste liquid tanks 3-1, 3-2, and check valves 2-1 are respectively installed on the pipelines , 2-2, the bottoms of the waste liquid tanks 3-1, 3-2 are equipped with outlets, which are connected by pipelines, and check valves 2-3, 2-4 are respectively installed on the pipelines to control the discharge. The pipelines equipped with check valves 2-3 and 2-4 are connected to the mechanical hydraulic diaphragm metering pump 4-1, and the squeezed water is metered and pumped into the regulating kettle 5 by the mechanical hydraulic diaphragm metering pump 4-1. Add 0.05% by weight of flocculant polymerize...

Embodiment 2

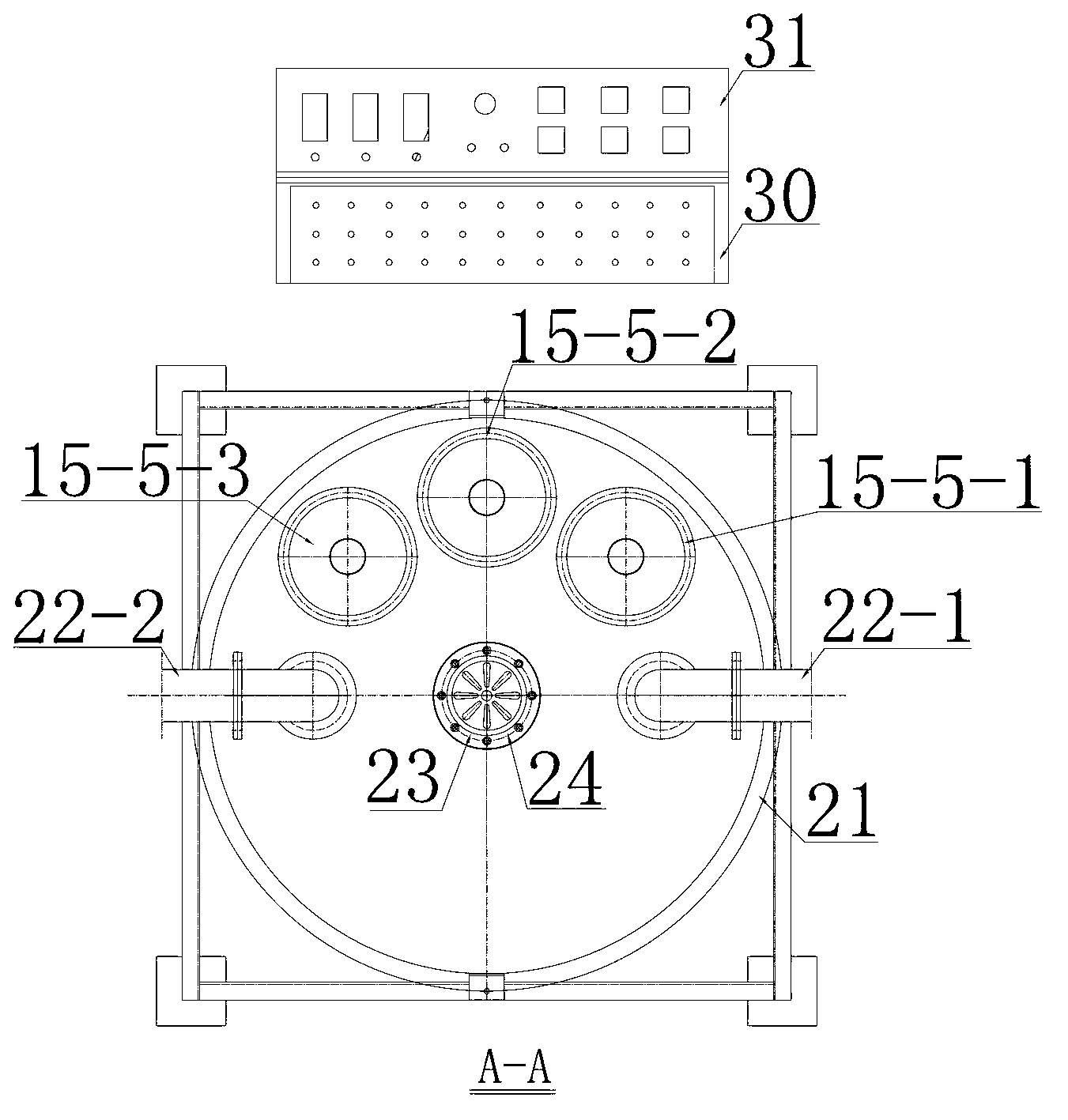

[0027] With the mechanical-hydraulic diaphragm metering pump 4-6, the B-grade clean liquid fuel of Example 1 in the finished product tank 12-1 or 12-2 or 12-3 is pumped into the multifunctional reaction tank 10-2 by the required amount through the pipeline, Enter from feed port 22-1, then gasoline and ammonia liquid additive are added respectively from the feed port 22-2 of multifunctional reaction tank 10-2, the add-on of gasoline additive is 7 weights of B grade clean liquid fuel amount %, the add-on of ammoniacal liquor additive is 5% by weight of B grade clean waste liquid fuel, thus starts the mixing system on the multifunctional reaction tank 10-2 to stir at a slow speed for 30 minutes, then in the additive feeding of multifunctional reaction tank 10-2 Port 15-5-1, 15-5-2, and 15-5-3 add potassium permanganate, hydrogen peroxide, and camphor essence additives respectively, and the addition amounts are respectively 0.2% by weight and 0.03% by weight of the amount of B-leve...

Embodiment 3

[0029] Example 3 The steps of industrialized production of clean liquid fuel are the same as in Example 1, except that the ratio of feed squeezed water:methanol is 35:65 parts by weight, and the combustion furnace temperature of Class B clean liquid fuel can reach 900 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com