Anti-hydrolysis poly urethane (PU) environment-friendly sole, manufacture method and manufacture mould thereof

A technology of shoe sole mold and manufacturing method, which is applied in the field of shoe manufacturing, can solve problems such as short service life, poor elasticity, and non-environmental protection, and achieve the effects of reducing production costs, easy size control, and low mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

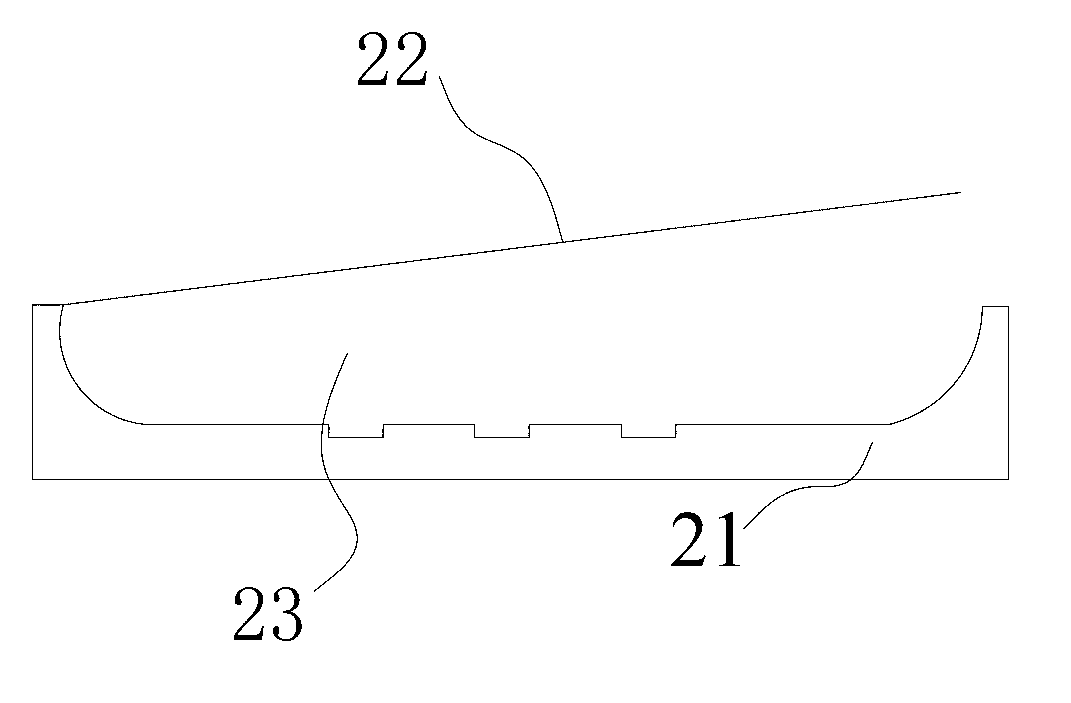

[0032] Such as figure 1 As shown, the anti-hydrolysis PU elastic environment-friendly shoe sole 1 of the present invention comprises a large bottom 11 and a PU foam layer 12, the large bottom 11 is provided with an accommodation cavity, and the PU foam layer 12 is made of low-density PU particles and filled The agent is foamed in the outsole, and the mass ratio of low-density PU particles to filler is 1:3-4. In the present invention, the filler is one or a mixture of two or more of activated carbon, spices, desiccants and medicinal powder for treating foot diseases. In the production process of shoes, the midsole and insole with perforation are used on the sole to produce shoes. When walking on the shoe, the PU foam layer is squeezed under the pressure of the foot, and the air in the shoe passes through the middle. The perforation between the sole and the insole is in contact with the filler, so the sweat and odor produced by the foot during walking can be effectively absorbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com