Fermentation type air-dried beef and production method of fermentation type air-dried beef

A production method and technology for air-drying beef, applied in the fields of application, food preparation, food science, etc., can solve the problems of hidden safety hazards of food additives and spices, poor taste and color of fermented meat products, etc. Digestion and quality enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

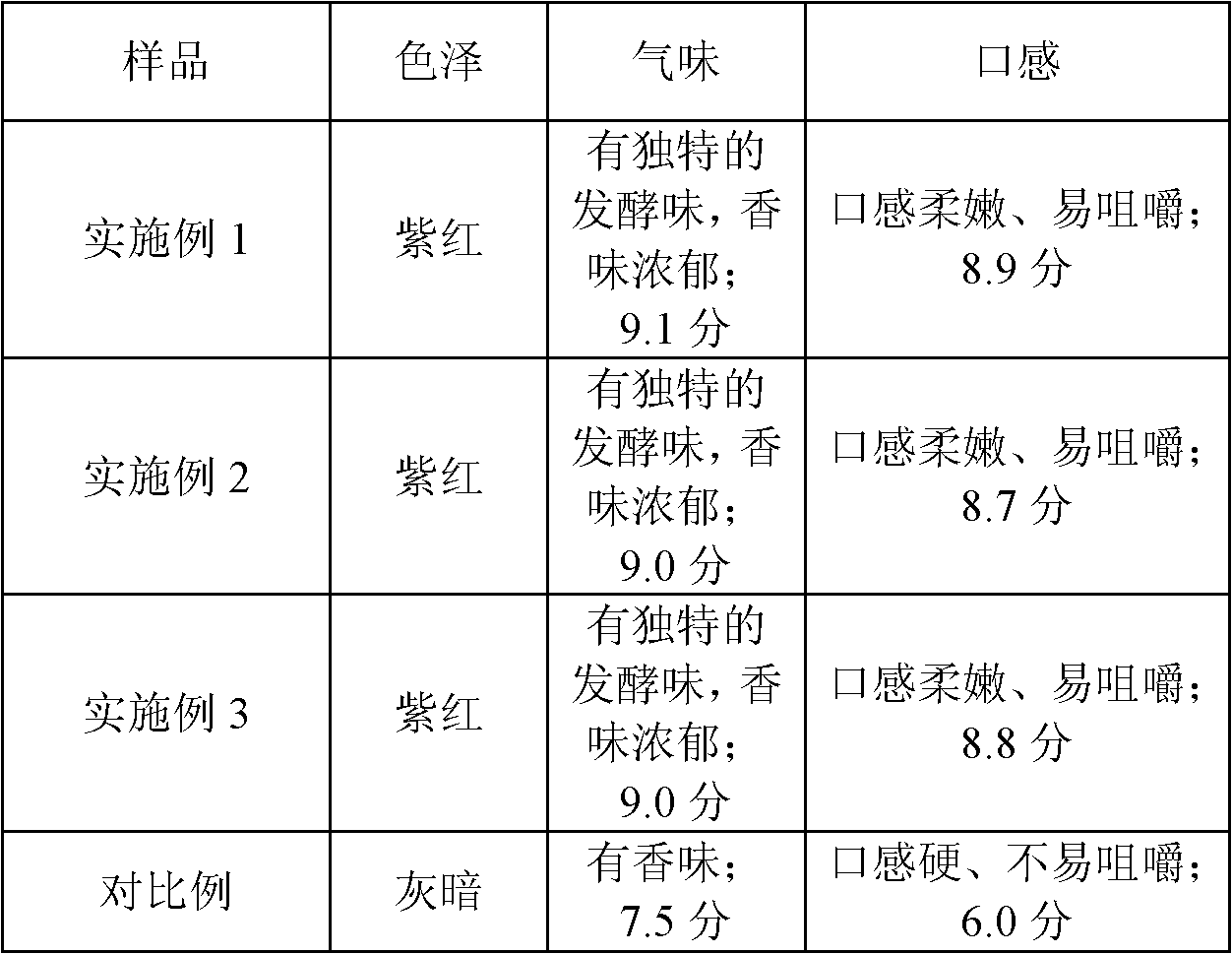

Examples

Embodiment 1

[0033] Adopt the following steps to produce fermented type air-dried beef:

[0034] 1) Choose raw meat: use qualified chilled fresh beef sirloin (three grilled and one Lin).

[0035] 2) Trimming: at an ambient temperature of 0-10°C, remove all the fat, tendons, and lymphatic lesion tissues on the raw meat.

[0036] 3) Fragment pulling: the trimmed raw meat is stretched according to the requirements of product specifications.

[0037] 4) Rolling and marinating: the vacuum rolling machine is cleaned and then disinfected, and then the meat strips are rolled and marinated for 10 minutes at an ambient temperature of 0-4°C. The marinating materials used in the rolling and kneading marinade include auxiliary materials and lactic acid bacteria TEXEL DCM-1, wherein the lactic acid bacteria TEXEL DCM-1 is purchased from Danisco, and the auxiliary materials include salt, white sugar and glucose, and are based on beef raw materials , the addition amount of auxiliary materials is 2.41wt%, ...

Embodiment 2

[0053] Adopt the same steps and methods as in Example 1 to produce fermented air-dried beef, the difference is that in the marinade used for rolling and marinating, the beef raw material is used as a benchmark, and the amount of auxiliary materials added is 2.30wt%, and the lactic acid bacteria TEXEL DCM- 1 The amount added is 0.0090%.

Embodiment 3

[0055] Adopt the same steps and methods as in Example 1 to produce fermented air-dried beef, the difference is that in the marinade used for tumbling and marinating, the beef raw material is used as a benchmark, and the amount of auxiliary materials added is 2.50wt%, and the lactic acid bacteria TEXEL DCM- 1 The amount added is 0.0125%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com