Spinneret plate microscopic examination instrument

A technology of a microscope and a spinneret is applied in the field of a spinneret microscope, which can solve the problems of low work efficiency and high labor intensity, and achieve the effects of convenient dredging, convenient operation and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

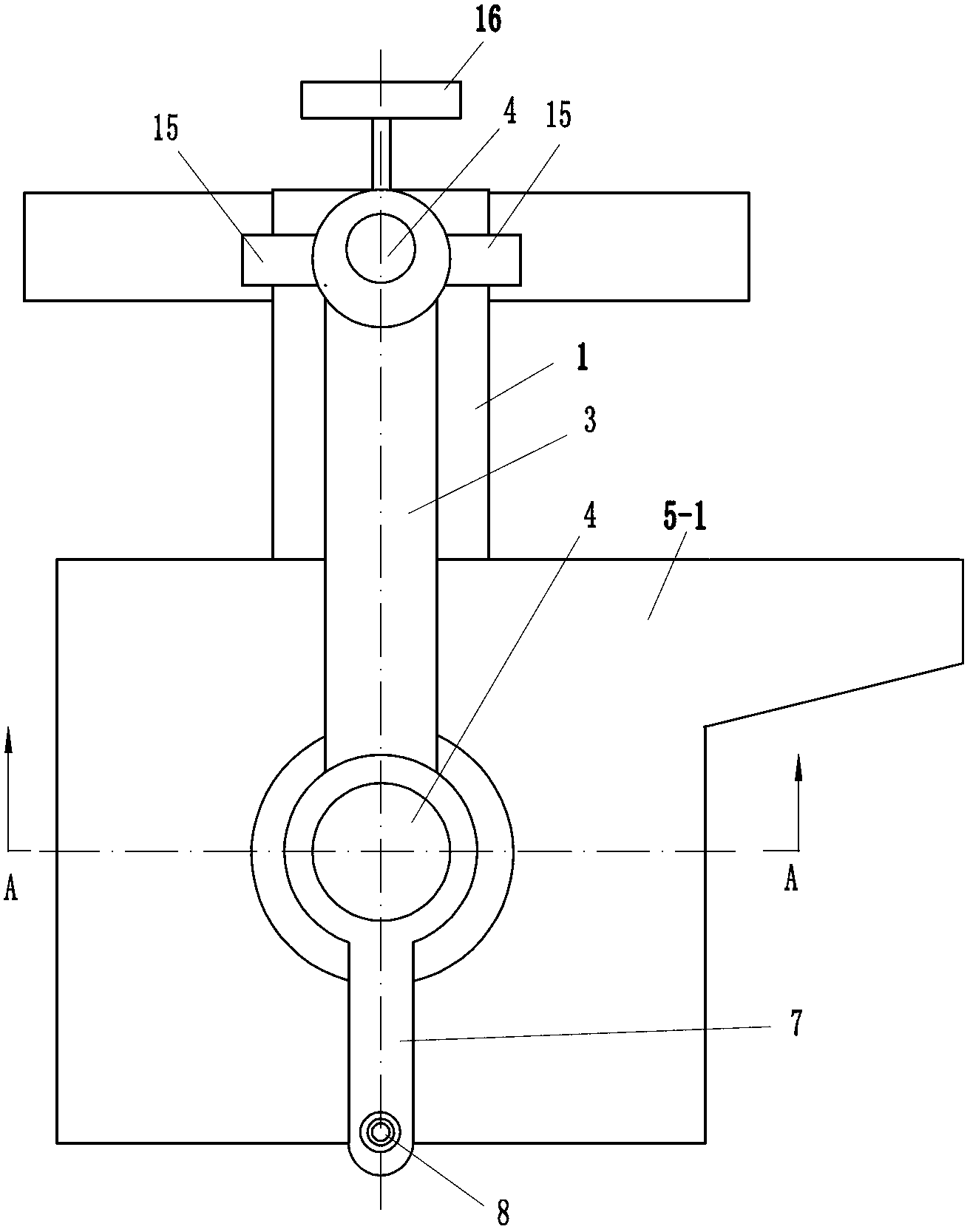

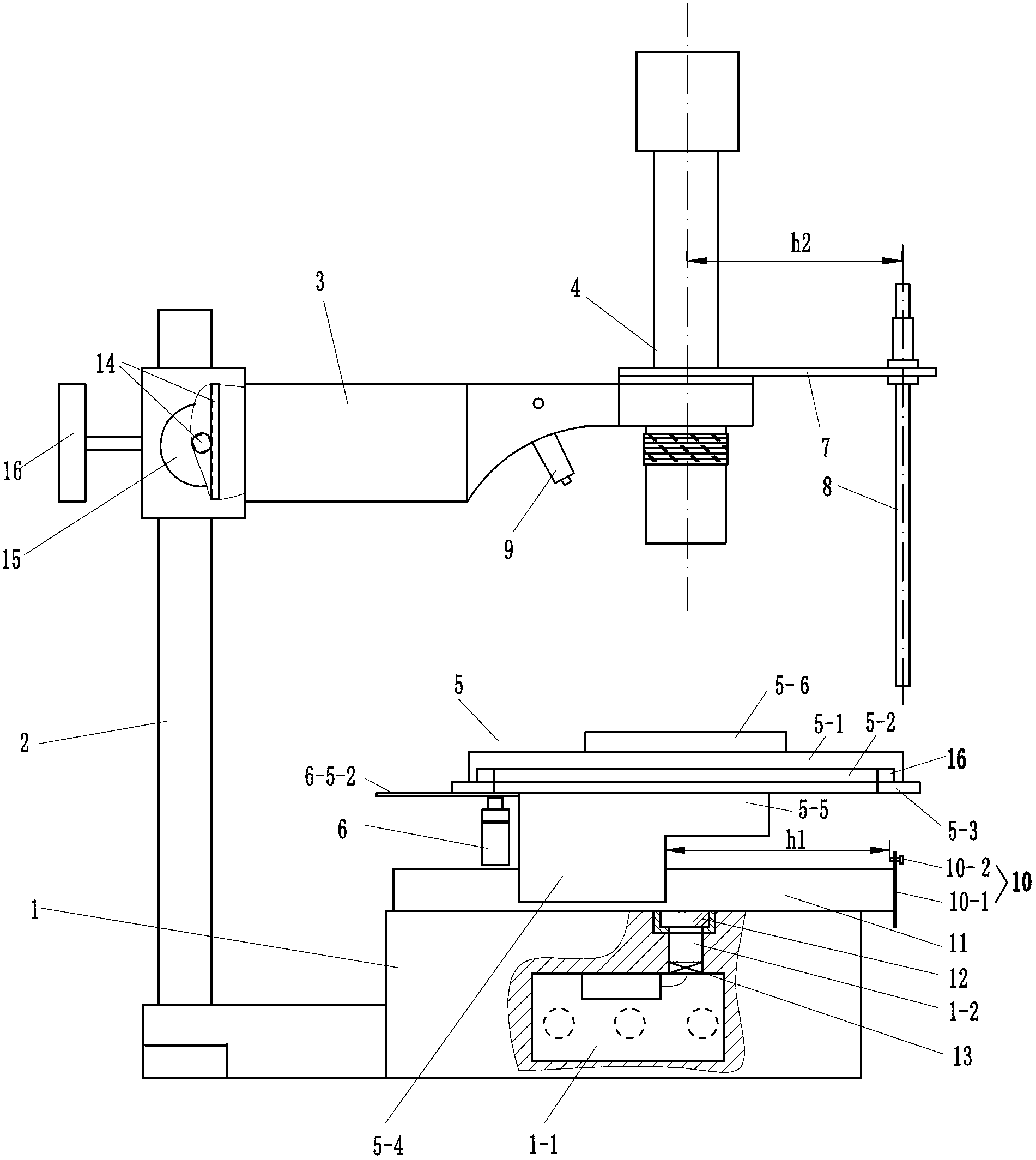

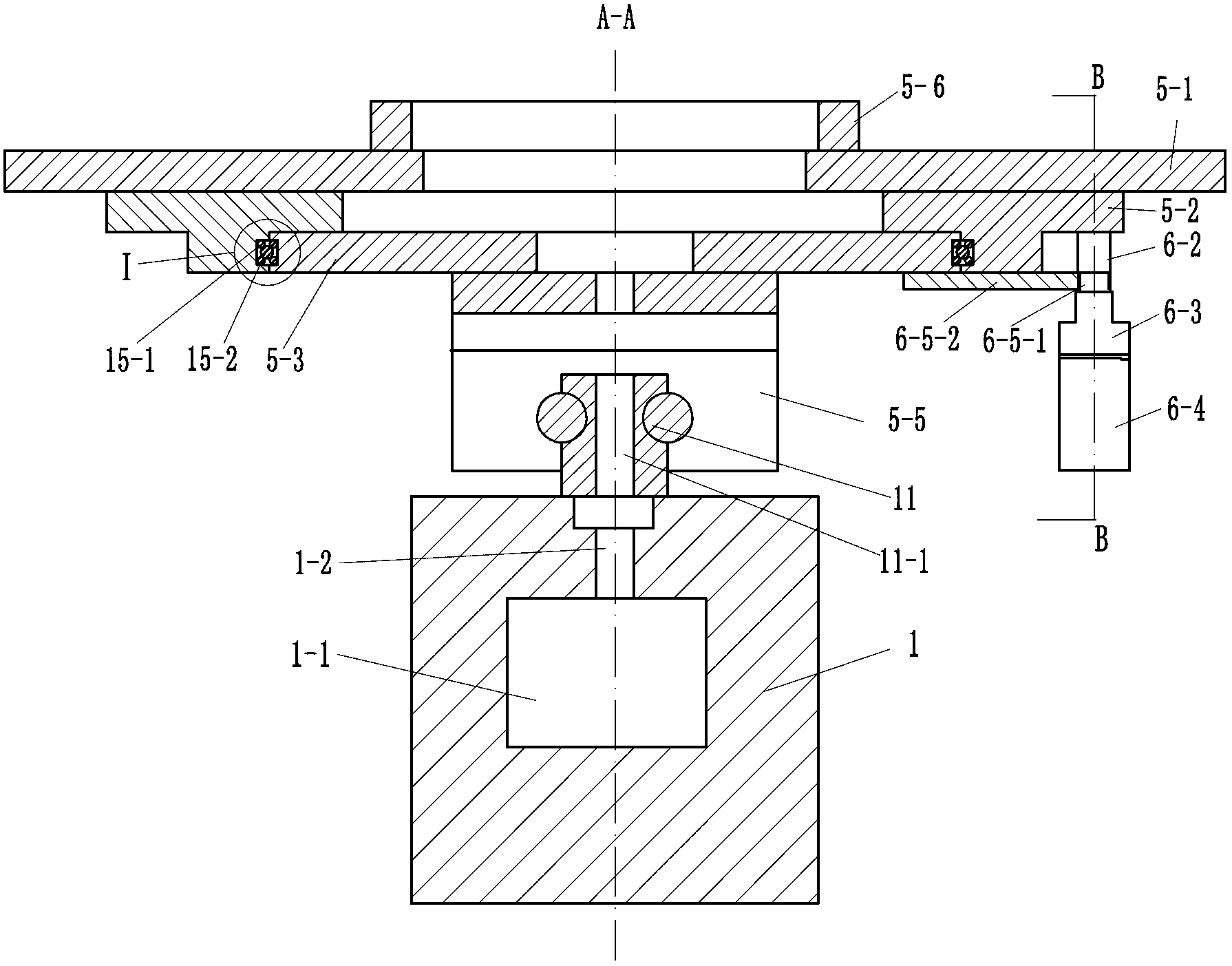

[0017] See Figure 1 to Figure 5 , the present embodiment has a base 1, a pillar 2 fixed on the base 1, a cantilever 3 that can be lifted on the pillar 2, a coaxial microscope 4 with a CCD camera installed on the cantilever 3, and can move forward and backward on the base 1 The workbench 5 further includes a workbench adjusting device 6 and a light source 13 . An elevating rack and pinion pair 14 is arranged between the pillar 2 and the cantilever 3, and the gear 14-1 of the elevating rack and pinion pair 14 is driven by the hand wheel 15 to rotate, and the rack 14-2 drives the cantilever 3 to elevate. The cantilever 3 is locked on the support 2 by the locking screw 16 .

[0018] The workbench 5 has a base plate 5-3, a support plate 5-2 slidably connected to the base plate 5-3, and a table 5-1 slidably connected to the support plate 5-2. The platen 5-1, the supporting plate 5-2 and the bottom plate 5-3 are all provided with light-transmitting holes; the bottom side of the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com