Suspended type fiber grating vibration sensor

A fiber grating, vibration sensor technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of slow attenuation of sensor free vibration, affecting sensor performance, low sensor sensitivity, etc., to facilitate quasi-distributed Multi-point real-time monitoring, anti-electromagnetic interference, the effect of increasing the measurement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

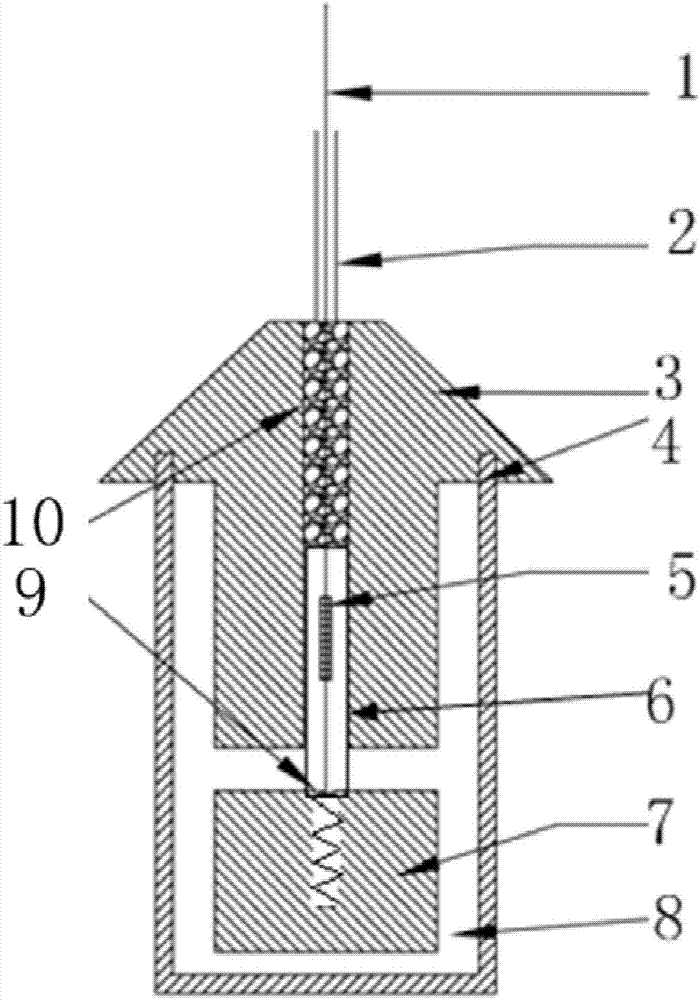

[0021] Example: such as figure 1 As shown, the present invention includes a housing, a signal transmission optical fiber 1, a protective sleeve 2, a fiber grating 5, and a vibrator 7. The housing is composed of a hollow screw 3 and a cylindrical protective shell 4. The shape of the hollow screw 3 is Umbrella structure, the bottom of the cylindrical protective shell 4 is sealed, and the upper port is threaded, which can be connected with the hollow screw 3 through the thread. The signal transmission optical fiber 1 and the protective sleeve 2 wrapped around it are bonded to the hollow top of the hollow screw 3 with colloid 10. The lower end of the signal transmission optical fiber 1 is placed with a fiber grating 5, and the fiber grating 5 is coated with a layer of elastic The polymer material 6 and the lower part of the fiber grating 5 are connected with the vibrator 7 through a spring 9 .

[0022] In this embodiment, the elastic polymer material 6 has a columnar structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com