Electronic expansion valve and manufacturing method therefor

An electronic expansion valve and valve needle technology, applied in lighting and heating equipment, climate sustainability, fluid circulation arrangements, etc., can solve problems such as large internal leakage, hidden dangers of product reliability, and stuck.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The core of the present invention is to provide an electronic expansion valve, which improves the nut and its matching relationship, so as to increase the coaxiality between the nut and the valve seat and ensure the reliability of the whole machine. Two embodiments will be described in detail below in conjunction with the accompanying drawings.

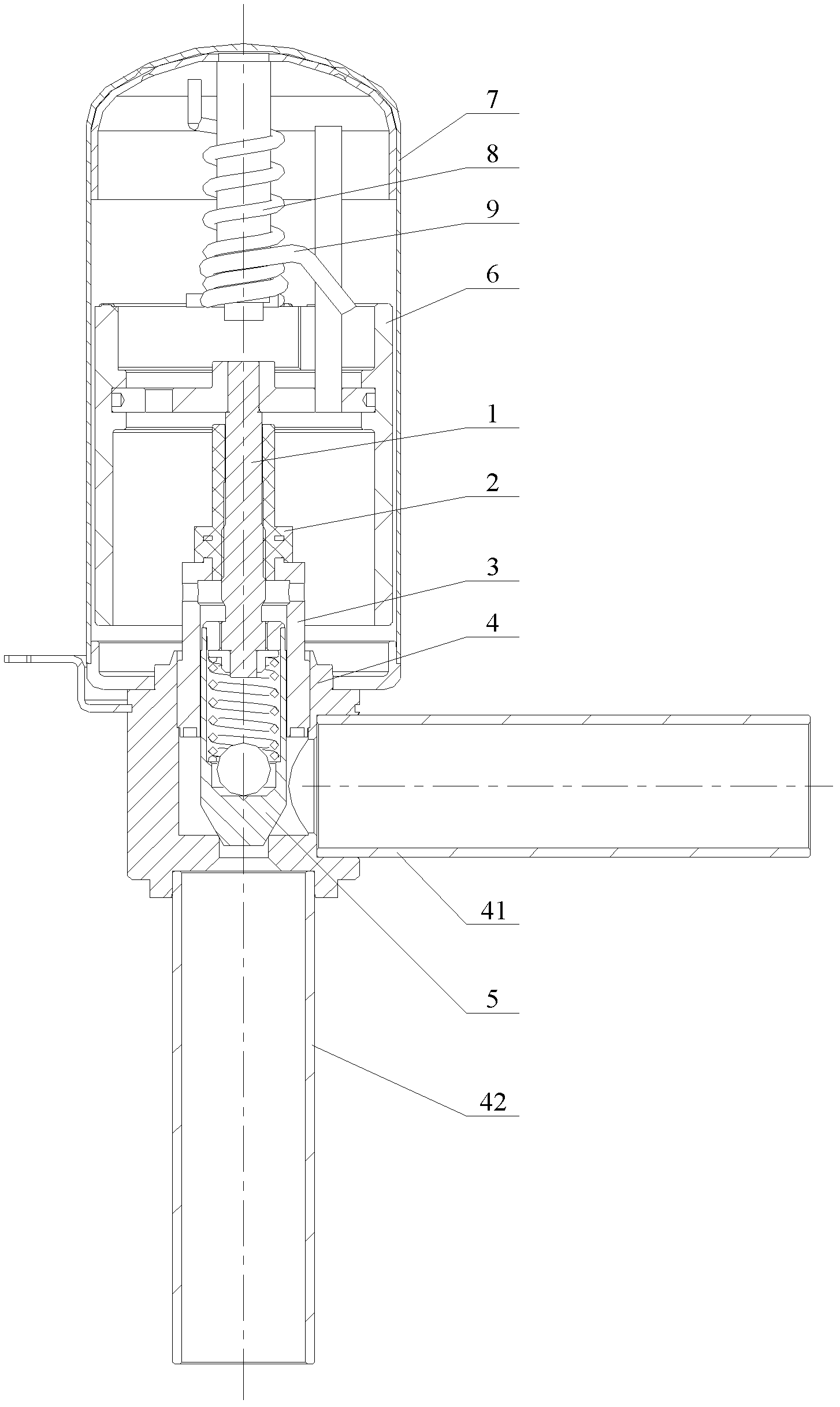

[0035] See figure 2 , which is a schematic diagram of the overall structure of the valve body of the electronic expansion valve described in the first embodiment.

[0036] Same as the prior art, the electronic expansion valve is mainly composed of two main parts: a valve body and a coil (not shown in the figure), and the rotor 6 and the coil in the valve body form a stepping motor. Such as figure 2 As shown, parts such as the valve seat 4, the inlet connecting pipe 42, and the outlet connecting pipe 41 form the valve seat assembly through a brazing process, and the shell 7 and the valve seat 4 form an inlet and outlet (the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com