Angle steel

A technology of angle steel and outer arc, applied in towers, joists, girders, etc., can solve the problems of stress concentration of cross-connected plates, great influence of angle steel stiffness, and reduction of angle steel cross-sectional characteristics, so as to improve the strength of rolls and reduce grinding. The effect of reducing the workload and reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

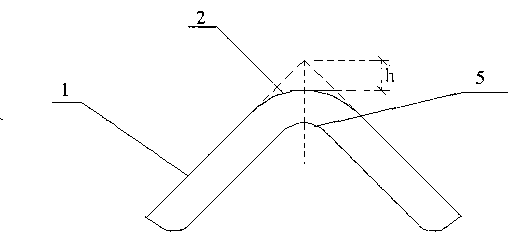

[0024] This example figure 1 shown. In the present embodiment, the outer arc A is tangent to the outer sides of the two limbs, and the radius R of the outer arc A is 5mm. According to formula 1, the point of intersection between the vertex of the outer arc A and the extension line of the outer sides of the two limbs is The distance h between them is 2mm.

[0025] The L100 angle steel produced by using the above parameters has an influence ratio of 0.42% on the cross-sectional area of the angle steel, and an influence ratio of 0.49% on the radius of inertia.

Embodiment 2

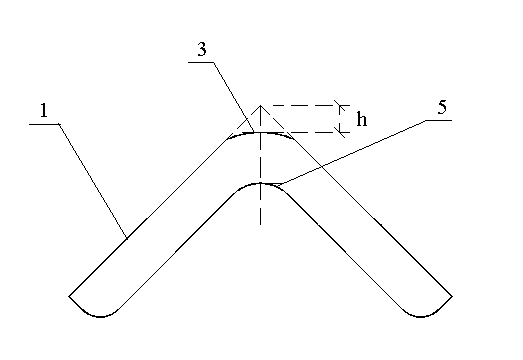

[0027] This example figure 2 shown. In this embodiment, the outer arc B intersects the outer sides of the two limbs, and the radius R of the outer arc B is 12.5 mm. The distance h between them is 5mm.

[0028] The L220 angle steel produced by using the above parameters has an influence ratio of 0.46% on the cross-sectional area of the angle steel, and an influence ratio of 0.57% on the radius of inertia.

Embodiment 3

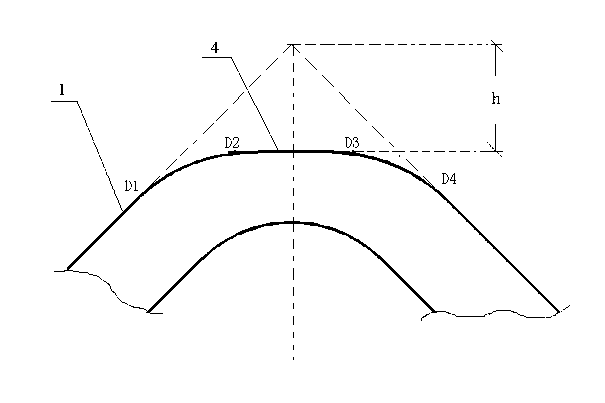

[0030] This example image 3 shown. In this embodiment, the two ends of the outer arc C and the two limbs are respectively tangent to the outer sides of the two limbs through two sections of arc D1D2 and arc D3D4, and the radius R of the outer arc C is 15mm. According to formula 1, The distance h between the vertex of the outer arc C and the intersection of the extension lines of the lateral sides of the two limbs is 6 mm.

[0031] The L250 angle steel produced by using the above parameters has an influence ratio of 0.51% on the cross-sectional area of the angle steel, and an influence ratio of 0.59% on the radius of inertia.

[0032] Certainly, the outer circular arc of the present invention can be connected with the outer sides of the two limbs in any form of transition, and the distance h between the apex of the outer circular arc and the intersection of the extension lines of the outer sides of the two limbs can also be 2 mm to 6 mm. Any value in between; the angle ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com