Polyphenyl core panel composite heat insulation external wall panel

A polystyrene core board, composite thermal insulation technology, applied in the direction of synthetic resin layered products, building components, layered products, etc., can solve the problems of high production requirements, high cost, empty drums, etc., to improve project quality and construction progress , the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

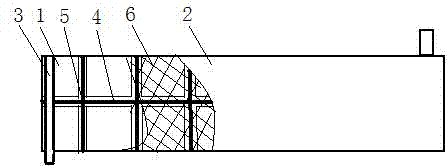

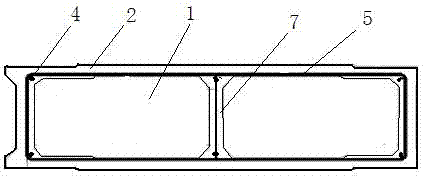

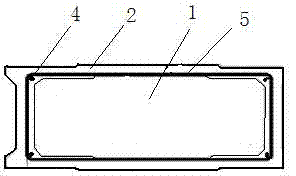

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] As shown in the figure: a polyphenylene core board composite thermal insulation exterior wall board, including a polyphenylene core board 1, a lightweight thermal insulation mortar shell layer 2 and connecting iron parts 3, the thickness of the thermal insulation mortar layer is not less than 10mm, and the thermal insulation mortar layer It is composed of cement, fly ash, lightweight aggregate and rubber powder. The weight percentage of each component is cement 15%-30%, fly ash 55%-70%, light aggregate 10%-15%, rubber powder 1%-3%, the lightweight aggregate is slag with a particle size of 5-60 mesh, the front and back of the polyphenylene core board 1 along the length direction are respectively provided with linear longitudinal reinforcement grooves, and the polyphenylene core board 1 is provided with rings along the width direction Reinforcing bar groove, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com