Device for automatic blanking of three-plate mold spreader channel cold slug

A technology of automatic material cutting and flow diversion, which is applied in the field of material cutting mechanism, can solve the problems of high work intensity, excessive labor, and labor-intensive work, and achieve the effects of improving efficiency, reducing work intensity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

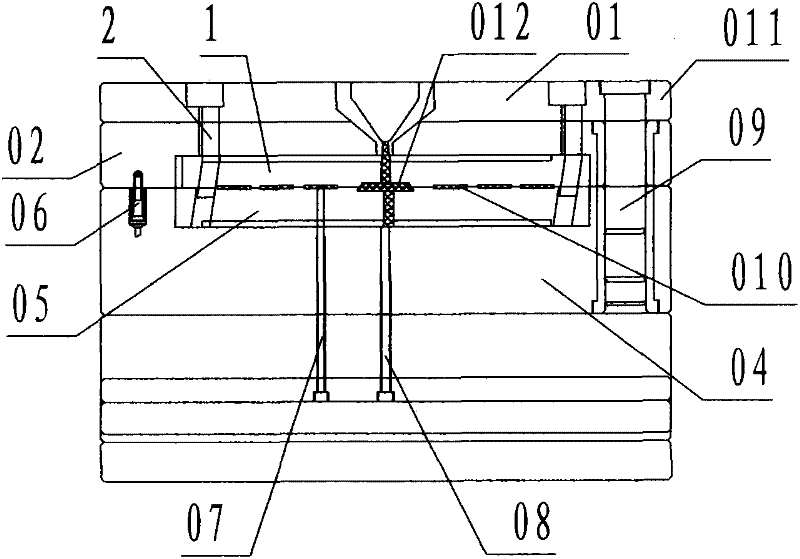

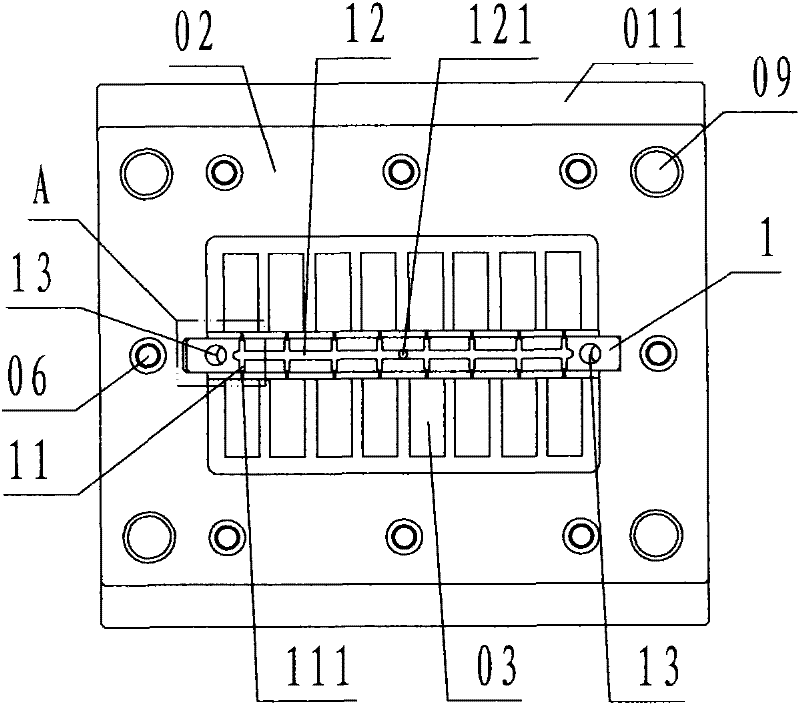

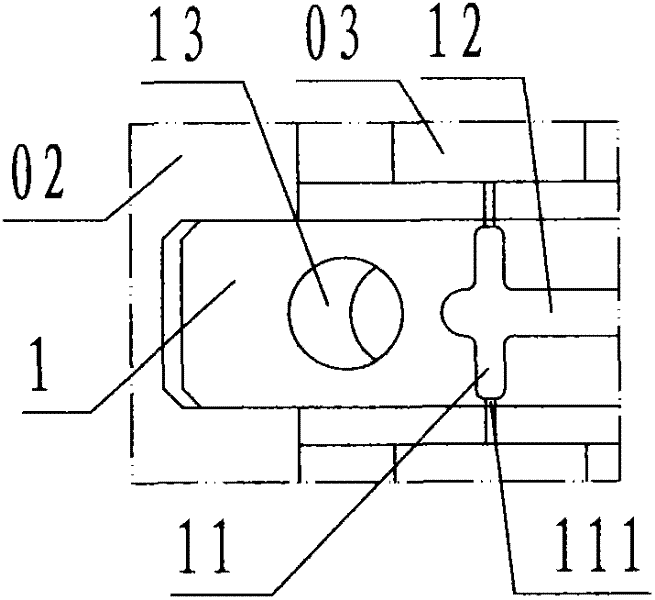

[0019] refer to Figure 1 to Figure 5 , an automatic cutting mechanism for the cold material head of the three-plate mold runner channel of the present invention, including a sliding manifold 1, a toggle rod 2, and a pulling plate 02, wherein: the sliding manifold 1 is a steel rectangular strip As a plate member, the center of the sliding manifold 1 is provided with a circular through hole corresponding to the butt hole of the pulling plate 02, which is called the main runner hole 121; the lower edge of the sliding manifold 1 is along the center parallel to the long side Line, is provided with the sprue 12 that is made of elongated groove, and described sprue 12 communicates with described sprue hole 121; The runner 11 formed by the connected grooves, the runner 11 is located at one end of the long side of the sliding manifold 1 and is provided with a thin runner 111 formed by a groove connected to the gate of the product; the two sides of the long side of the sliding manifold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com