Stamping reinforcement method of weak rolling area of roadbed and application thereof

A reinforcement and subgrade technology, applied in roads, roads, buildings, etc., can solve problems such as difficult design and operation by construction units, increased cost of backfilling at the back of the abutment, complex construction technology, etc., to reduce vehicle operating costs and improve road operation quality , technically reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The stamping reinforcement method of the subgrade weak rolling area of the present invention and its application will be described in conjunction with the accompanying drawings and embodiments.

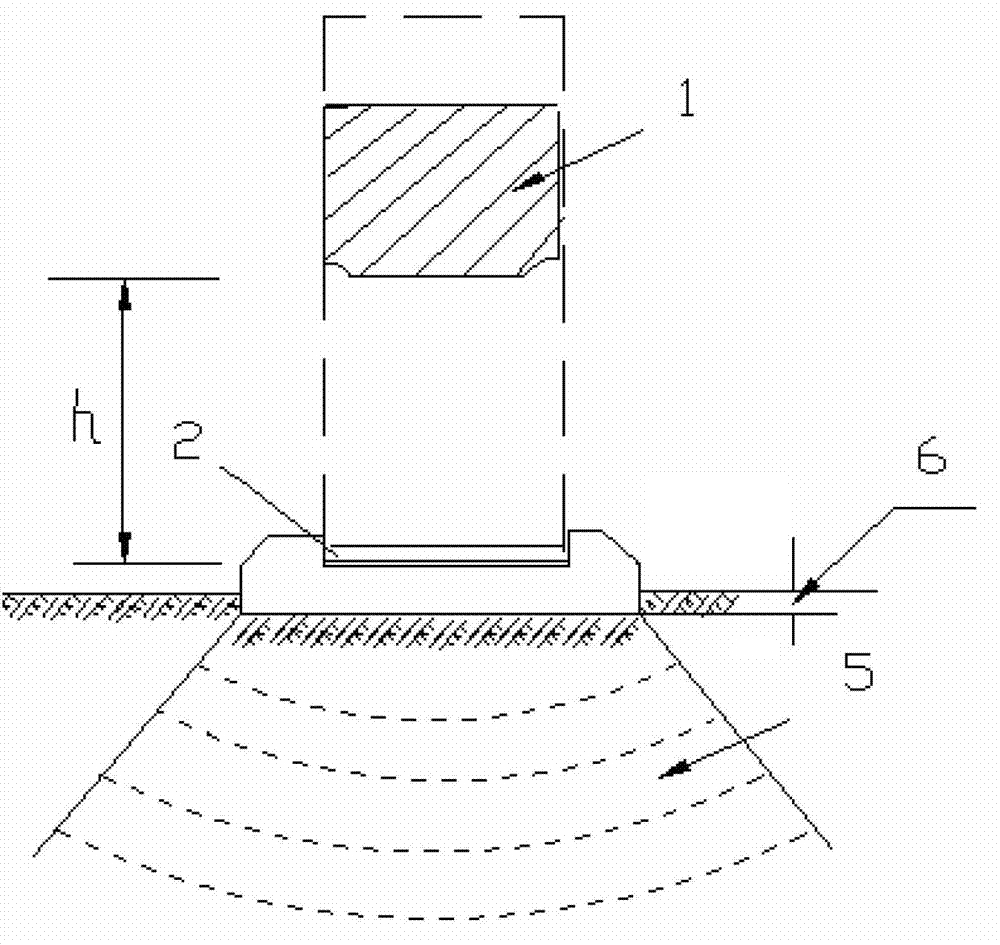

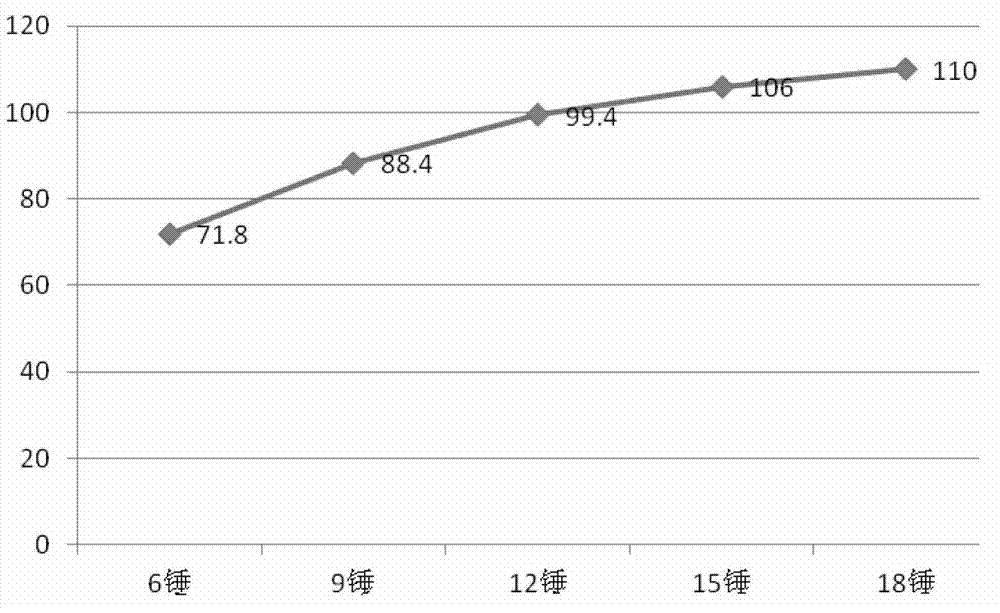

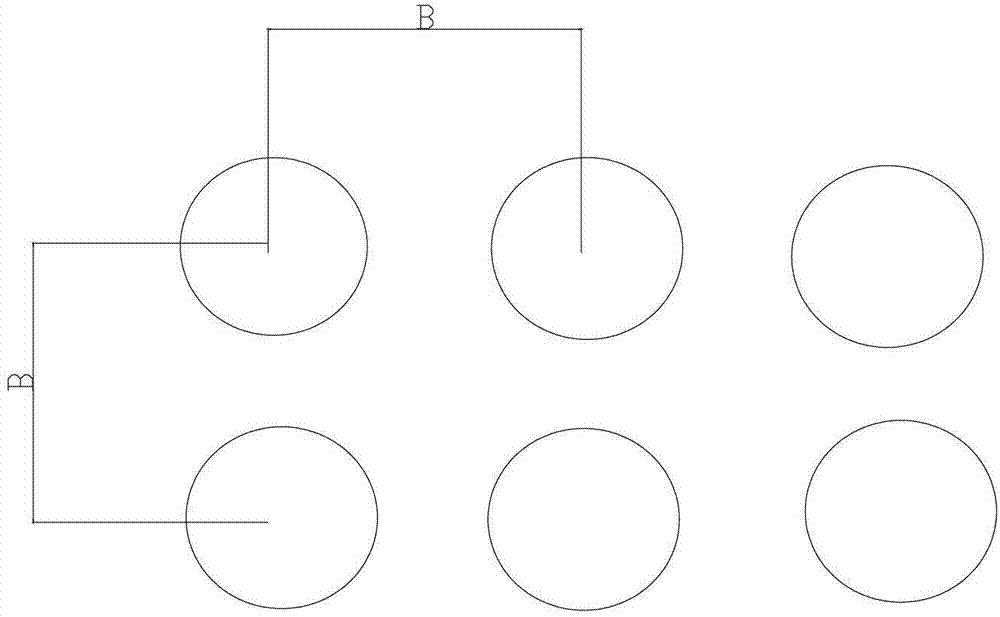

[0042] figure 1 It is a schematic diagram of the stamping reinforcement principle of the present invention, which shows the working principle of the stamping reinforcement machine. figure 2 The schematic diagram of single-point stamping times for stamping and strengthening operation is determined for the trial stamping settlement of the present invention, which shows the curve of the settlement produced by trial stamping, and the single-point stamping times for stamping and reinforcement operations are determined with three-hammer settlement less than 10mm. image 3 It is a stamping and reinforcement layout diagram of the tamping plate spacing S of the present invention, indicating a schematic diagram of the plane layout of the tamping plate for stamping and reinforcement co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com