Real silk flame retardant and method for preparing flame-retardant real silk

A technology of flame retardant and silk, applied in the field of durable flame retardant finishing, to achieve the effect of convenient operation and long-lasting good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

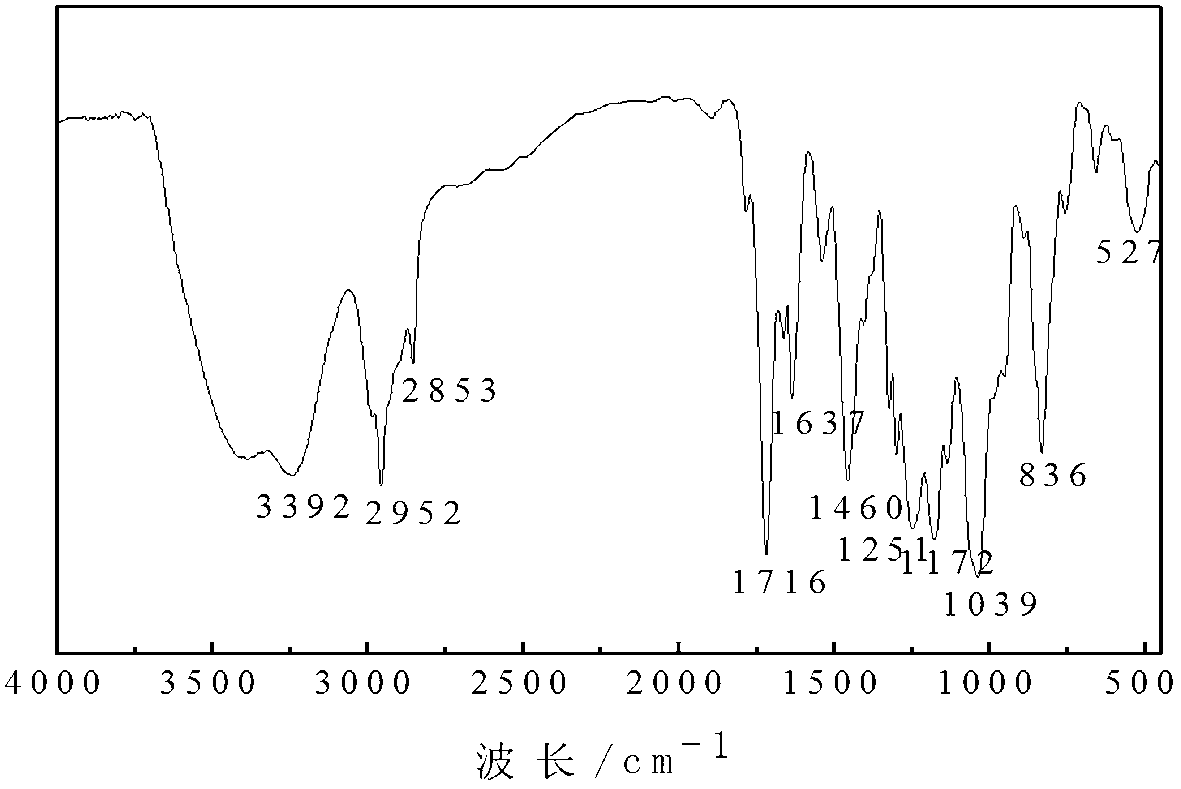

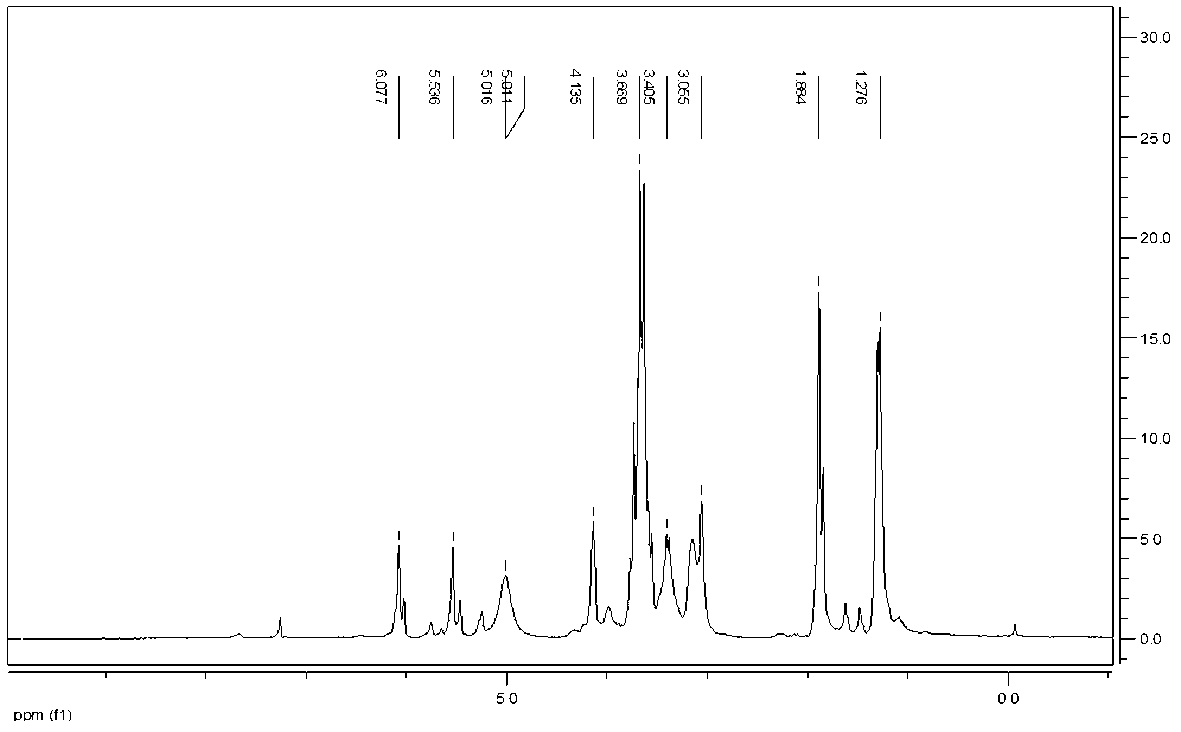

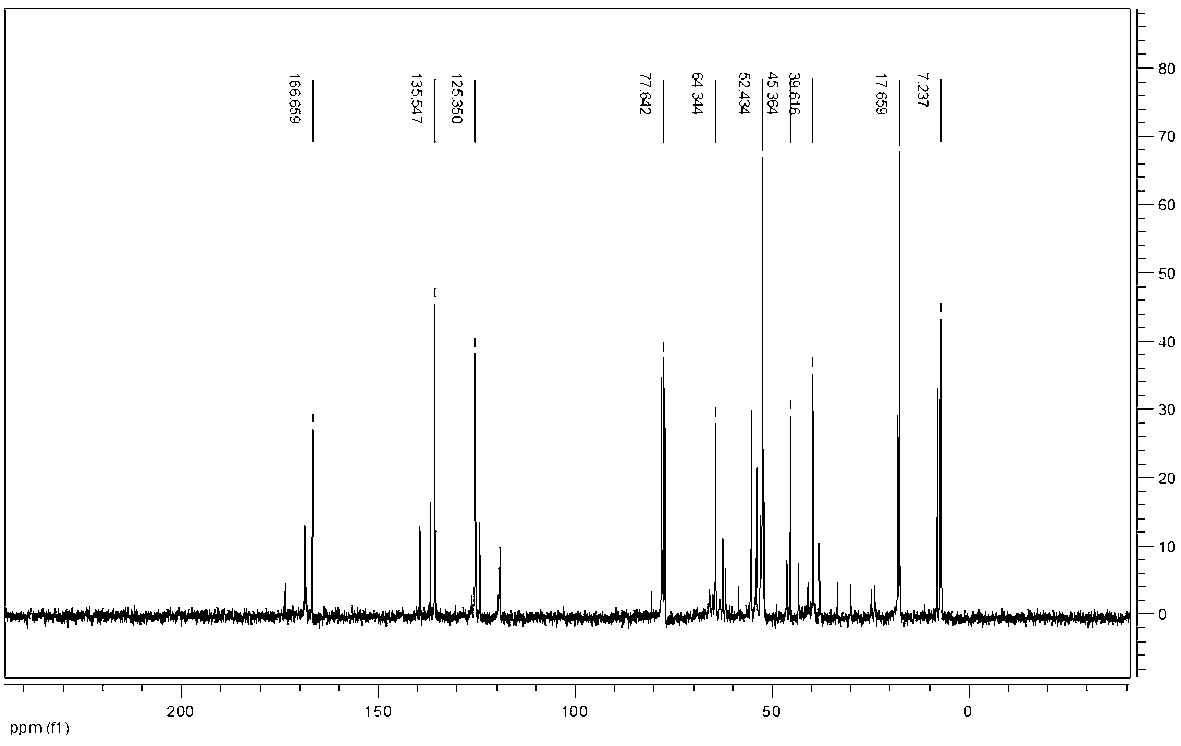

[0039] Example 1: Preparation of flame retardant.

[0040] The structural formula of the flame retardant prepared in this embodiment is:

[0041]

[0042] where R is CH 3 , n is 1, and the name is methacryloyloxyethyl dimethoxyphosphoramide.

[0043] It is prepared by the following method:

[0044] The first step: preparation of dimethyl chlorophosphate

[0045] After mixing 6.4g (0.1mol) of anhydrous methanol with 20.2g (0.2mol) of anhydrous triethylamine, slowly drop into a constant pressure dropping funnel containing 15.33g (0.1mol) of phosphorus oxychloride and In a four-neck flask containing 100g of anhydrous diethyl ether mixed solution, stir and pass nitrogen gas, control the dropping speed to 3-5s / drop, and the reaction temperature to 0-5°C. After the dropwise addition, keep the temperature at 0-5°C Continue to react for 5-6 hours. After the reaction, it was suction filtered to remove salt, and then rotary evaporated to obtain a colorless liquid.

[0046] The ...

Embodiment 2

[0055] Embodiment two: real silk fabric (real silk power spinning, 36g / m 2 ) flame retardant finishing and performance testing

[0056] Carry out three groups of comparative tests, add the flame retardant prepared in Example 1 equivalent to 50%, 80%, and 100% of the weight of the real silk fabric into the beaker, then add water 30 times the weight of the real silk fabric, add 3% (mass percentage of the flame retardant) of potassium persulfate, adjust the pH of the flame retardant aqueous solution to 3.5 with ammonia water, put it into the silk fabric for immersion, raise the temperature to 90°C, keep it warm for 1 hour, then take it out, wash it with cold running water, and use it again Wash at 50°C for 10 minutes, then wash with cold running water, and then dry at 70°C.

[0057] After flame-retardant finishing, the oxygen index of the fabric was tested according to GB5454-85, and the carbon length of the fabric was tested according to GB5456-85. The results are shown in Tabl...

Embodiment 3

[0062] Example 3: Flame-retardant finishing and performance testing of real silk fiber (20 / 21D degummed silk, degumming rate 23%)

[0063] Add 50% (to the mass percentage of real silk fiber) of the flame retardant obtained in Example 1 into the beaker, then add 20 (to the mass percentage of real silk fiber) deionized water, and then add 2.5% (to the mass percentage of the real silk fiber) of the flame retardant mass percent) of ammonium persulfate, adjust the pH of the flame retardant aqueous solution to 3.5 with ammonia water, immerse it in silk fabrics, raise the temperature to 90°C, keep it warm for 1 hour, then take it out, wash it with cold running water, and then wash it with 50°C water for 10 minutes , and then washed in cold running water, then dried at 70. It is measured that the weight gain rate of the treated real silk fiber is 9%.

[0064] Since silk fibers do not have corresponding standards for testing oxygen index and carbon length, the flame retardant performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com