Sliding hydrofoil boat for preventing sliding surface from splashing

A sliding surface and wing skid technology, which is applied in the field of wing skids and high-performance ships, can solve the problems of strict weight distribution, impact on economy, serious impact, etc., to improve impact and course stability, and comprehensive technical and economic performance Excellent, the effect of overcoming inflexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

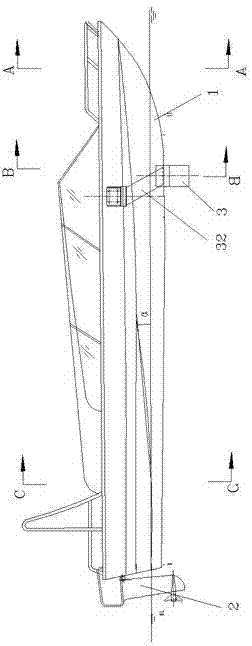

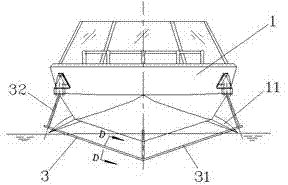

[0021] Such as figure 1 , figure 2 As shown, the present invention includes a hull 1, a propulsion device 2 and a hydrofoil 3 arranged at the front of the hull, and the propulsion device 2 is arranged as follows for hulls 1 of different scales: the length of the hull 1 is 8-9 meters When the propulsion device 2 is less than or equal to 10 meters in length, the propulsion device 2 adopts an outboard engine; when the length of the hull 1 is more than 8-9 meters, an inboard engine full-cavitation propeller or an outboard engine all-cavitation propeller is used; when the hull length is more than 15 meters, except for using In addition to the propulsion of the above two devices, a landline full-cavitation propeller can also be used.

[0022] The cutting hydrofoil 3 includes a horizontal hydrofoil body 31 and several symmetrically arranged pillars 32. The hydrofoil body 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com