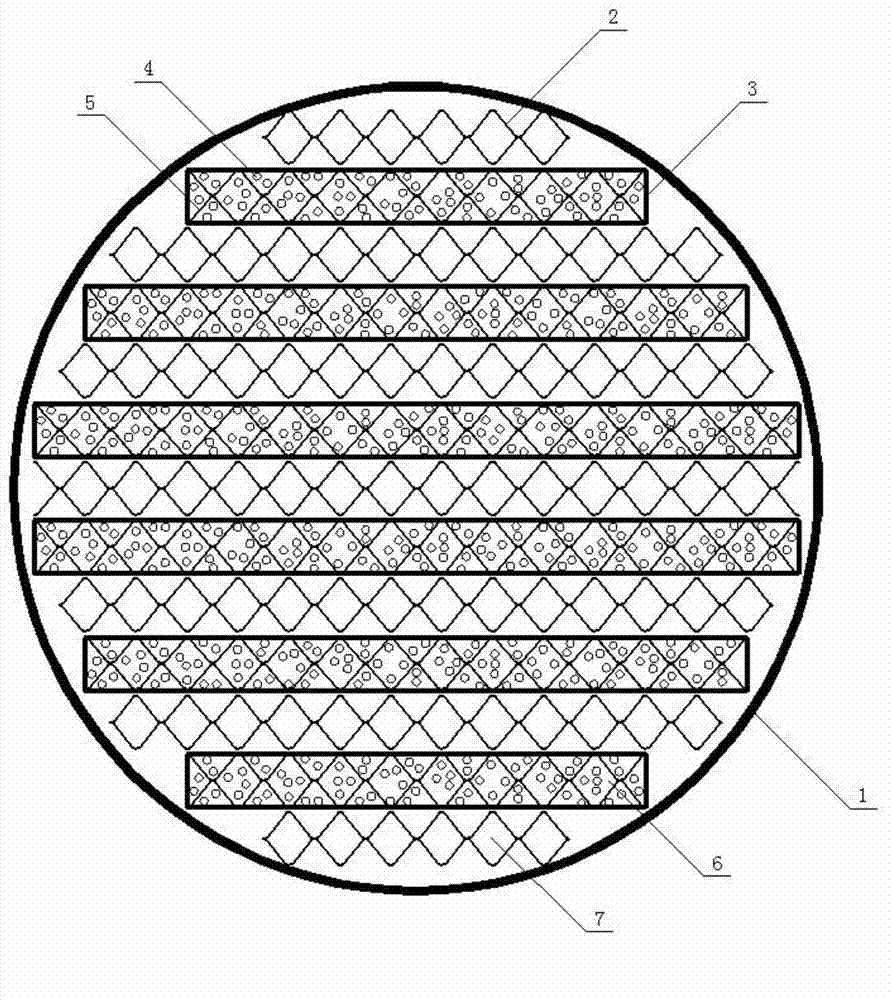

Catalytic distillation filler with alternative flow structure

A technology of catalytic rectification and flow structure, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve the problem of increasing the reaction surface area, increasing the pressure drop in the tower, plugging the packing layer, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

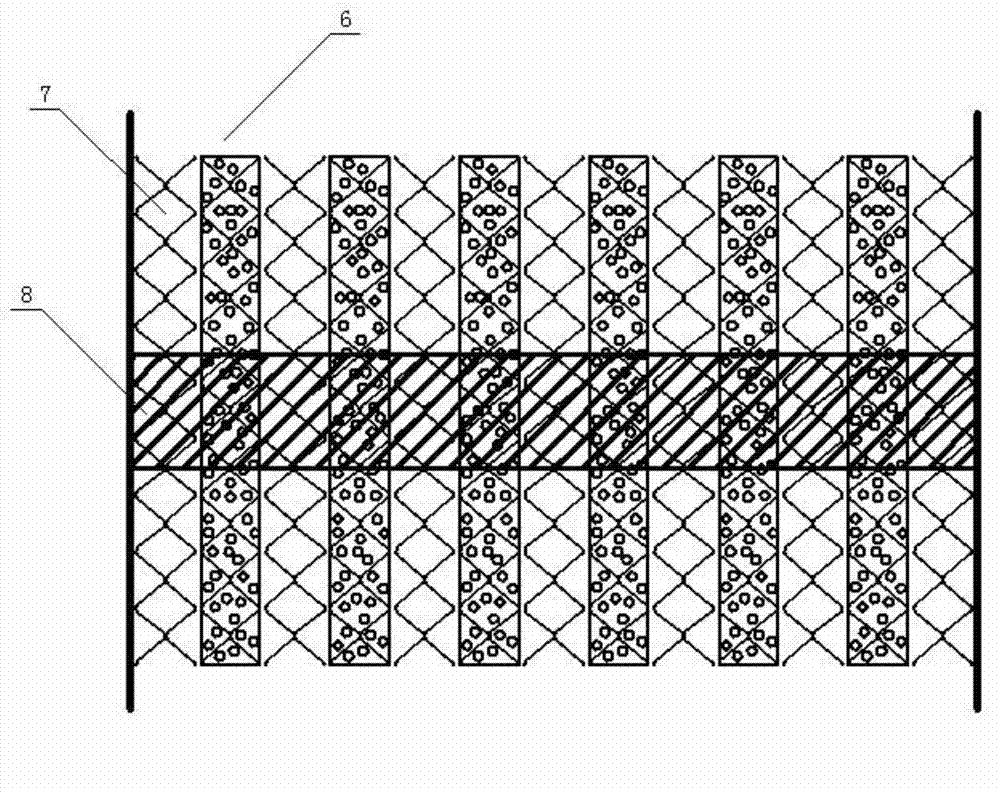

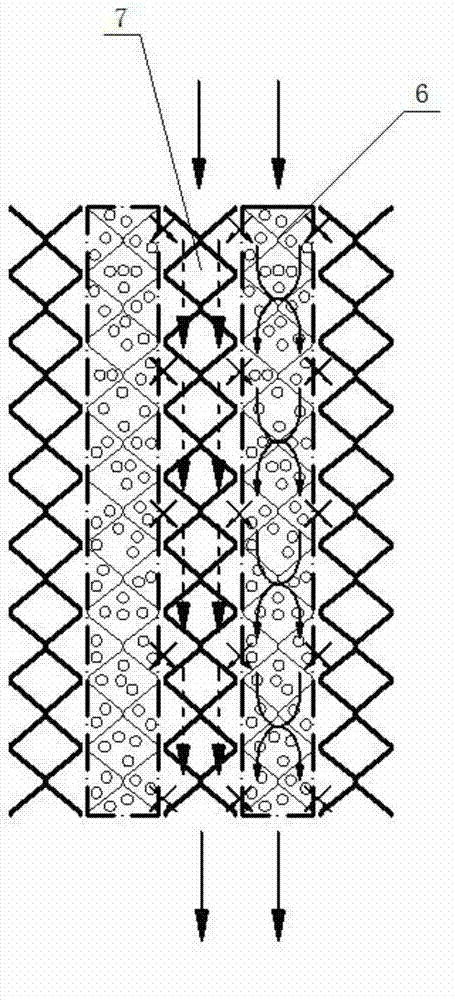

Method used

Image

Examples

specific Embodiment 1

[0022] In the raw material pretreatment of MTBE (methyl tert-butyl ether) plant, C 4 、C 5 For catalytic hydrogenation, the packing adopts window-opening diversion packing and metal calendered orifice corrugated packing. There are 15 packing sheets in each layer of packing disc, a total of 30 packing sheets, and there are 3 packing sheets in each component A and component B. , The wire mesh is made of stainless steel, the mesh number is 18 mesh, the tower diameter is DN600, and the upper and lower packings rotate 15°. The use of the catalytic rectification filler of the present invention is compared with the use of common bundled catalysts. Experiments show that the volume fraction of butadiene is reduced by more than 30%, the volume fraction of dimethyl ether is reduced by 9%-15%, and other impurities are reduced by 5%-23%. 2-Butene increased by more than 28%.

specific Embodiment 2

[0023] In the production of MTBE (methyl tert-butyl ether) equipment, the packing adopts window-opening diversion packing and metal orifice corrugated packing. There are 12 packing sheets in each layer of packing tray, a total of 24 packing sheets. Each component A and There are 2 packing sheets in component B, the wire mesh is made of stainless steel, the mesh number is 35 mesh, the tower diameter is DN600, and the upper and lower packings are rotated 90°. Using the catalytic rectification filler of the present invention compared with the use of common bundled catalysts, the methanol content is reduced by 12.8%, C 4 21.0% reduction in mixture, C 5 The mixture is reduced by 27.7%, other impurities are reduced by 10.3%-46.9%, and the MTBE content is increased by 1.61 percentage points.

specific Embodiment 3

[0024] During the hydrolysis process of methyl acetate, the fillers are window-opening diversion fillers and honeycomb fillers. There are 50 filler sheets in each layer of packing sheets, a total of 100 packing sheets, and there are 2 packing sheets in each component A and component B. The wire mesh is made of nylon, the mesh number is 60 mesh, the tower diameter is DN1200, the upper and lower packings are rotated 60°, and the packing discs are installed in blocks. Using the catalytic rectification filler of the present invention is compared with the use of common bundled catalysts, the hydrolysis rate of methyl acetate is increased by 5.3%-10.9%, and the product yield is increased by about 9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com