Vitamin C effervescent granule and preparation method thereof

A technology of effervescent granules and vitamins, which is applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., which can solve the problems of disintegration timeout, poor stability, and disintegration time easily affected by water temperature, etc. problems, to achieve the effect of increasing disintegration speed, improving stability, and facilitating storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

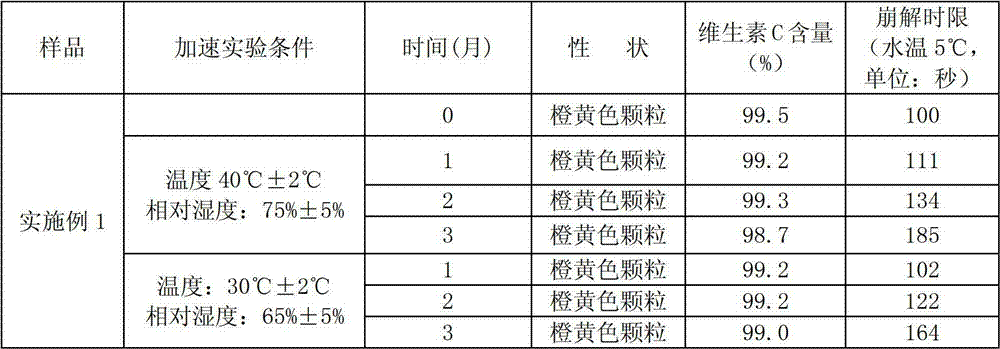

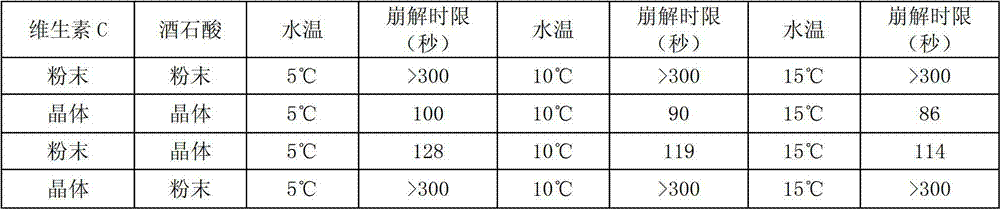

Examples

Embodiment 1

[0014] Acid Granules Recipe:

[0015] Vitamin C (40-60 mesh crystal) 150g; tartaric acid (40-60 mesh crystal) 1050g; sunset yellow 1g.

[0016] Alkali grain formula:

[0017] Sodium bicarbonate 1200g; Sodium chloride 30g; Sucrose 400g; Aspartame 50g; Sunset yellow 10g; Hydroxypropyl methylcellulose 5g.

[0018] Preparation process: Acid granules: Dissolve the prescribed amount of sunset yellow in an appropriate amount of 80% ethanol aqueous solution by ultrasonic to obtain an ethanol aqueous solution containing pigment. After mixing vitamin C and tartaric acid evenly according to the prescription amount, the soft material is prepared with the prepared ethanol aqueous solution containing pigment, granulated with a 24-mesh sieve, dried at 50°C, and sieved through a 16-mesh sieve and a 60-mesh sieve respectively.

[0019] Alkali Granules: Dissolve sunset yellow in 5% (w / w) hydroxypropyl methylcellulose (50cp) to obtain an aqueous binder solution containing pigment. After mixin...

Embodiment 2

[0022] Acid Granules Recipe:

[0023] Vitamin C (40 mesh-60 mesh) 450g; citric acid (40 mesh-60 mesh) 910g; sunset yellow 2g.

[0024] Alkali grain formula:

[0025] Sodium carbonate 1060g; Sodium chloride 6g; Sucrose 600g; Aspartame 25g; Sunset yellow 8g; Polyvinylpyrrolidone 8g.

[0026] Preparation process: Acid granules: Dissolve the prescribed amount of sunset yellow in an appropriate amount of 80% ethanol aqueous solution by ultrasonic to obtain an ethanol aqueous solution containing pigment. After mixing vitamin C and citric acid evenly according to the prescription amount, the soft material is prepared with the prepared ethanol aqueous solution containing pigment, granulated with a 24-mesh sieve, dried at 50°C, and sieved through a 16-mesh sieve and a 60-mesh sieve respectively.

[0027] Alkali particles: Dissolve sunset yellow in 12% (w / w) polyvinylpyrrolidone aqueous solution to obtain an aqueous binder solution containing pigment. Mix sodium carbonate, sodium chl...

Embodiment 3

[0030] Acid Granules Recipe:

[0031] Vitamin C (40-60 mesh) 200g; malic acid (40-60mesh) 1200g; tartrazine 1.5g.

[0032] Alkali grain formula:

[0033] Sodium bicarbonate 1320g; Sodium chloride 10g; Sucrose 100g; Aspartame 60g; Tartrazine 8.5g; Syrup 6g.

[0034] Preparation process: acid granule: Dissolve the prescribed amount of tartrazine in an appropriate amount of 70% ethanol aqueous solution by ultrasonic to obtain an ethanol aqueous solution containing pigment. After mixing vitamin C and malic acid evenly according to the prescription amount, the soft material is prepared with the prepared ethanol aqueous solution containing pigment, granulated with a 20-mesh sieve, dried at 40°C, and sieved through a 16-mesh sieve and a 60-mesh sieve respectively.

[0035] Alkali granules: Dissolve lemon yellow in 10% aqueous syrup solution to obtain an aqueous binder solution containing pigment. After mixing sodium bicarbonate, sodium chloride, sucrose and aspartame evenly accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com