Automatic film spreading and laminating device

A mulching device and automatic technology, applied in the direction of plant protection cover, etc., can solve the problems of affecting the use effect of mulching film, stretching and deformation of mulching film, waste of mulching film material, etc., and achieve high utilization rate of mulching film, small deformation of mulching film, and not easy to curl. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

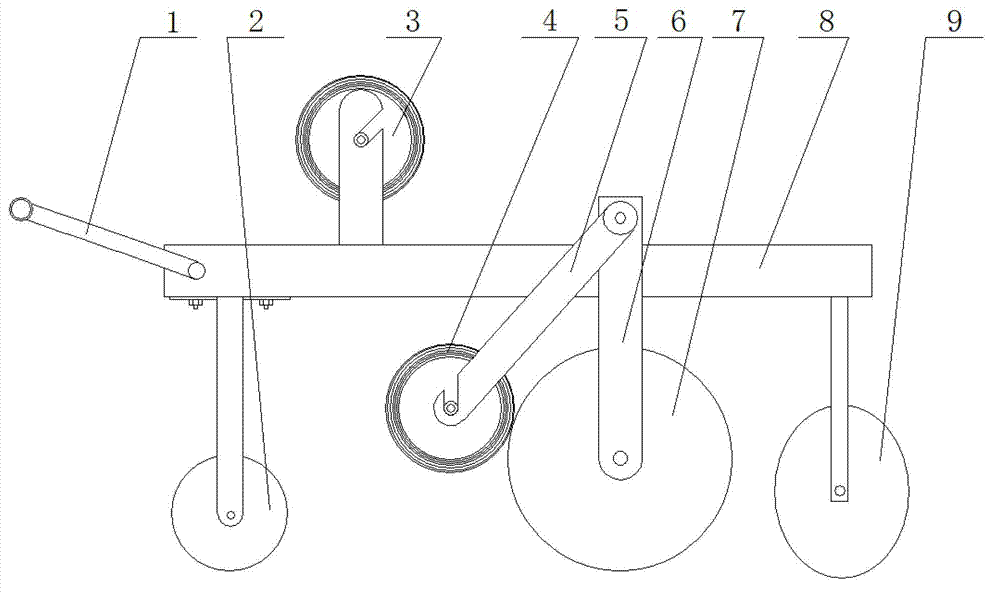

[0010] Such as figure 1 Shown, a kind of automatic spread coating device, comprises frame 8, walking wheel 2, covering soil plate 9, film roller 4, lamination roller 7; The film roller stand 5 of this device is hinged on frame 8 or lamination roller 6, the lamination roll frame 6 is fixed on the frame 8, the film roll 4 is in contact with the lamination roll 7, and the free end of the mulch is positioned at the tangent between the film roll and the lamination roll; ; Walking wheel 2 is located in front of laminating roller 7.

[0011] Working process and working principle:

[0012] When the present invention is in use, the spare film roll 3 is installed in the draw-in groove of the film roll frame 5, and the free end of the ground film is pulled out from the tangent place between the film roll and the pressure film roll, and fixed; the connecting mechanism 1 is connected with the traction device, when When the frame moves forward with the indexing device, the traveling wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com