Manufacturing method for high-pressure quick soft recovery diode with diffusing buffer layer

A recovery diode and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of voltage drop increase, voltage drop, loss of conductance modulation ability, etc., and achieve soft recovery characteristics and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

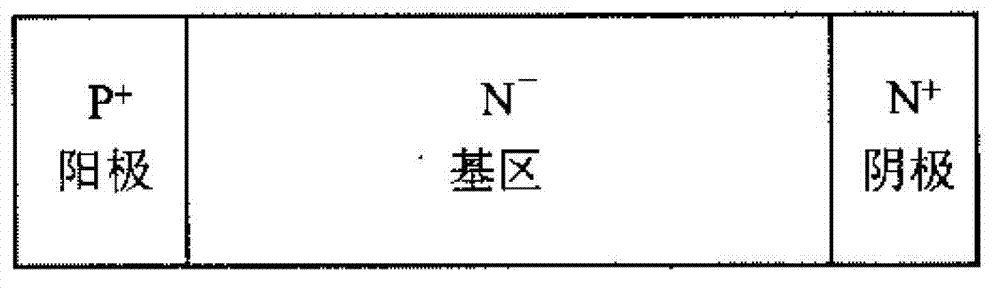

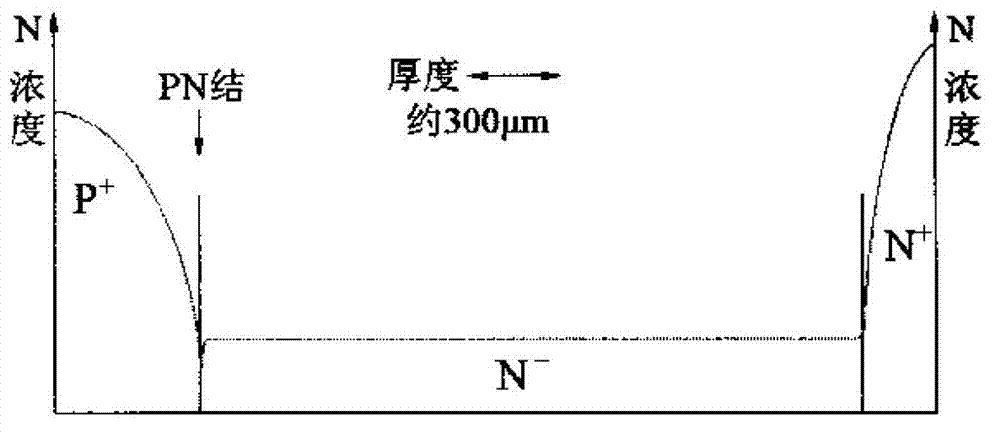

[0046] The invention proposes a manufacturing method of a high-voltage fast soft recovery diode with a diffusion buffer layer. Be described below in conjunction with accompanying drawing.

[0047] So far, buffer layers for fast recovery diodes have all been fabricated using a two-step epitaxy method. The main production steps are as follows: the raw material is silicon single crystal N + Substrate sheet, sheet thickness 500-600μm, doping concentration> 8×10 19 cm -3 ; at N + A thin layer with a concentration of 10 was grown on the substrate by epitaxy 14 cm -3 The range of silicon single crystal film is used as N buffer layer; then continue to epitaxially grow N on the N buffer layer - single crystal layer for diode N - Base and P + layer production.

[0048] The existing problems of making fast recovery diodes by epitaxial method are: 1. In view of the current technical level of epitaxial technology, the thickness of the epitaxial layer can only be up to 100 μm, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com