Adjustable scrapable high-voltage cable pitch coating device

A coating device and high-voltage cable technology, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of rough surface of the online sheath, scraping resistance, re-production of the cable outer sheath, etc., to solve the problem of spraying Unevenness, the effect of solving quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

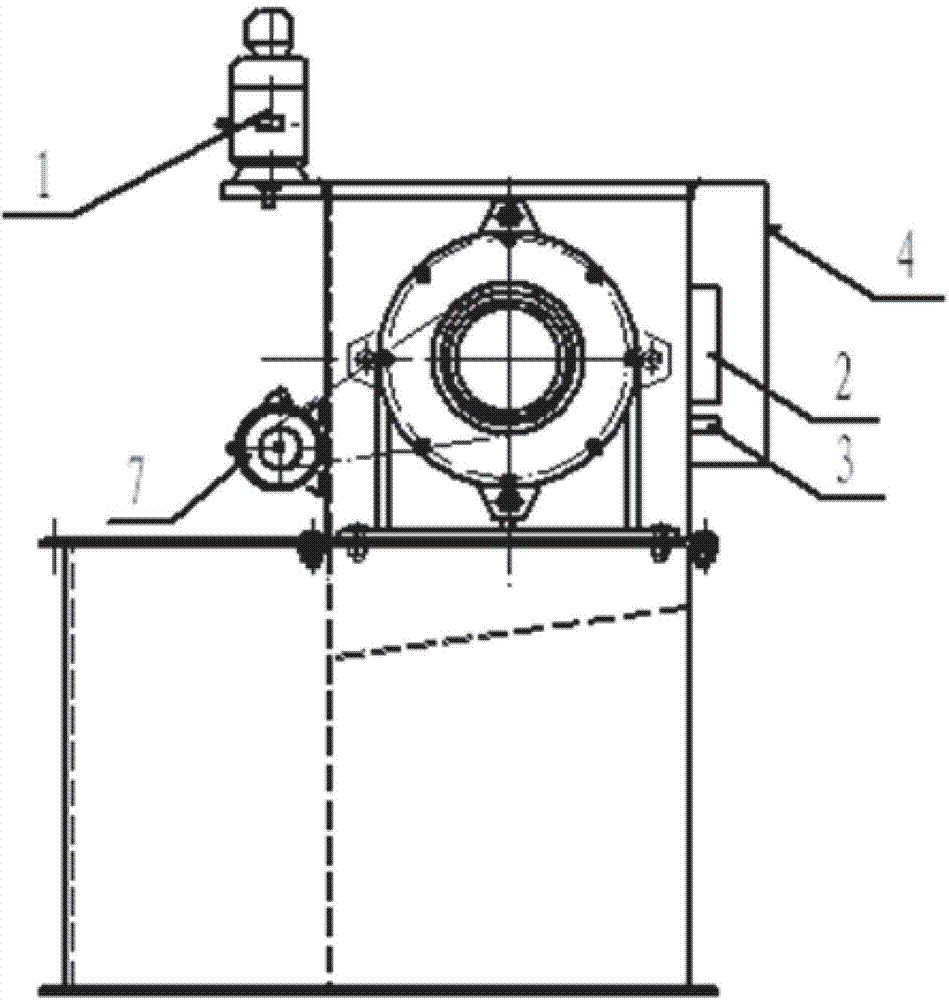

[0014] The existing high-voltage cable asphalt coating device directly delivers the asphalt to the spray nozzle through the asphalt pump, and its flow rate is difficult to control. Such as figure 1 , 2 As shown, the present invention adopts electric automation closed-loop to flow control by following parts on the basis of existing high-voltage cable asphalt coating device: variable frequency motor 1, frequency converter 2, PLC controller 3, potentiometer 4, shower nozzle 5 and Sprinkler device 6, asphalt flow control is given analog quantity by potentiometer 4, after digital calculation by PLC controller 3, the signal is transmitted to frequency converter 2, and the low-speed vector control frequency conversion motor 1 is set by frequency converter 2 to operate, and frequency conversion motor 1 The rotational speed of the pump controls the flow rate of the pump, so that the asphalt is sprayed out with an appropriate flow rate to the cable through the nozzle 5. In this proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com