Non-contact transformer auxiliary automatic cooling system and method

An automatic cooling and non-contact technology, applied in the field of transformer cooling, can solve the problems of obvious cooling effect and insufficient auxiliary cooling measures of transformers, so as to ensure the safety of personnel and equipment, improve aesthetics, and avoid maintenance work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

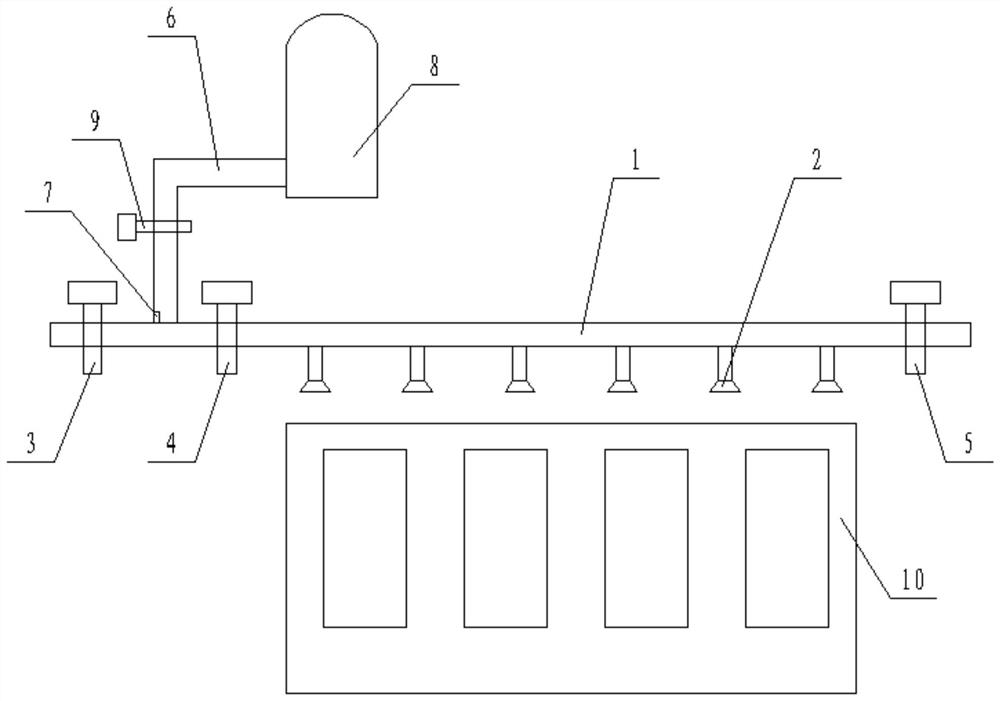

[0036] Such as figure 1 The shown non-contact transformer auxiliary automatic cooling system includes a temperature sensor used to collect the temperature of the transformer radiator, and the temperature sensor is connected to the temperature controller, time relay, intermediate relay, and electromagnetic water valve in sequence. The output end is connected to the spray pipe 1 through a hose, and several spray heads 2 are arranged on the spray pipe 1, and the spray heads 2 face the direction where the transformer is located.

[0037] Preferably, the intermediate relay is a contactor, and the contactor is used to control the electromagnetic water valve; the time relay is used to control the spraying time.

[0038] The device is characterized by small size, easy operation, arbitrarily expanded spraying system, and adaptability to transformers of various voltage levels.

Embodiment 2

[0040] Such as figure 1 and figure 2 As shown, on the basis of Embodiment 1, the spray pipe 1 is provided with a first shut-off valve 3, a second shut-off valve 4, and a third shut-off valve 5 in sequence along the direction from upstream to downstream. The first shut-off valve 3. The gas filling pipeline 6 is connected between the second shut-off valve 4, and the gas filling pipeline 6 communicates with the high-pressure gas source 8; the nozzle 2 is located between the second shut-off valve 4 and the third shut-off valve 5, and all nozzles are synchronized On and off. The gas filling pipeline 6 is located directly above the spray pipe 1 , and the axis of the gas filling pipeline 6 is perpendicular to the axis of the spray pipe 1 . A pressure sensor 7 is arranged on the inner wall of the gas filling pipeline 6 , and the pressure sensor 7 is located at the bottom of the gas filling pipeline 6 . A fourth shut-off valve 9 is arranged on the gas filling pipeline 6 , and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com