Direct-evaporation temperature and humidity exchange air-conditioning system

An air conditioning system, temperature and humidity technology, applied in air conditioning systems, heating and ventilation control systems, heating and ventilation safety systems, etc. and other problems, to achieve the effect of energy saving and water saving, reducing labor intensity and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

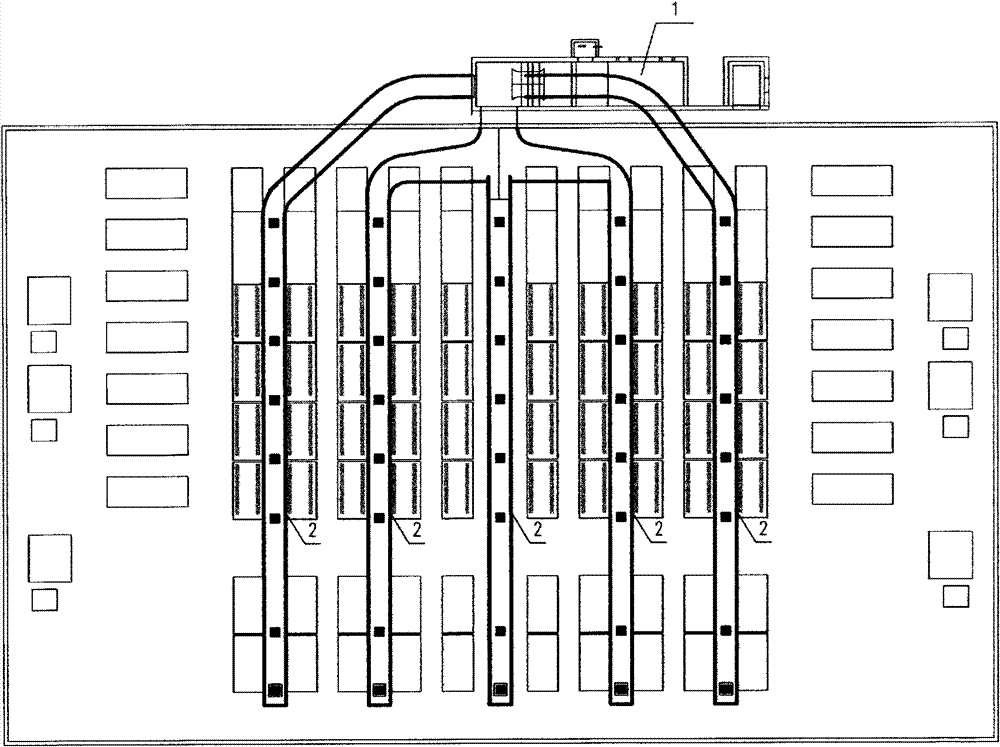

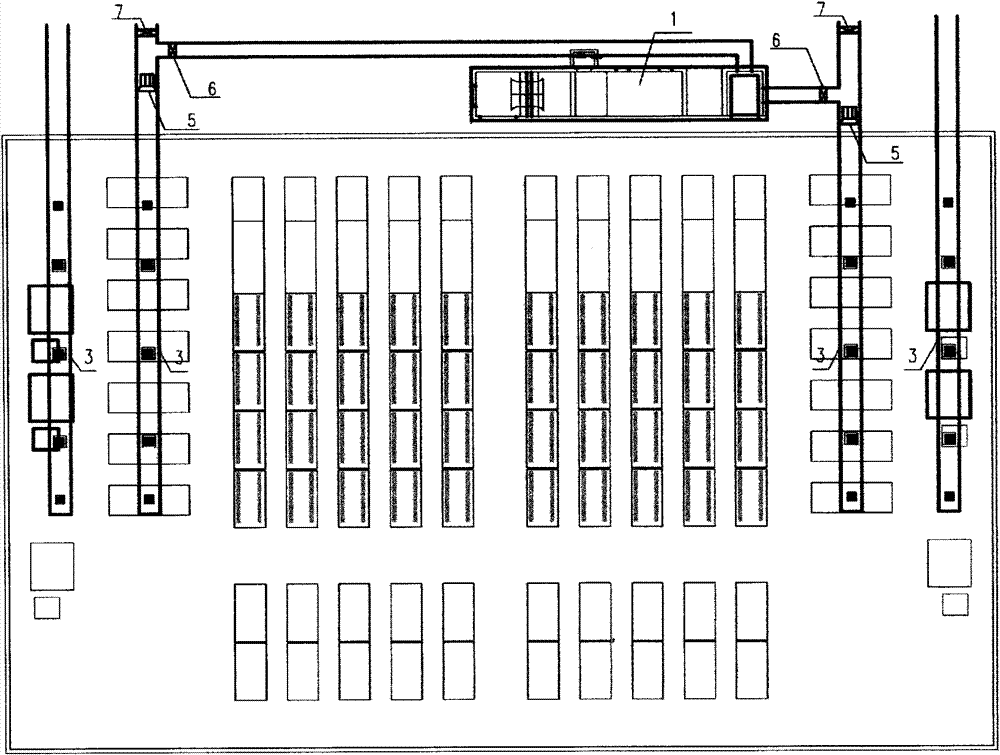

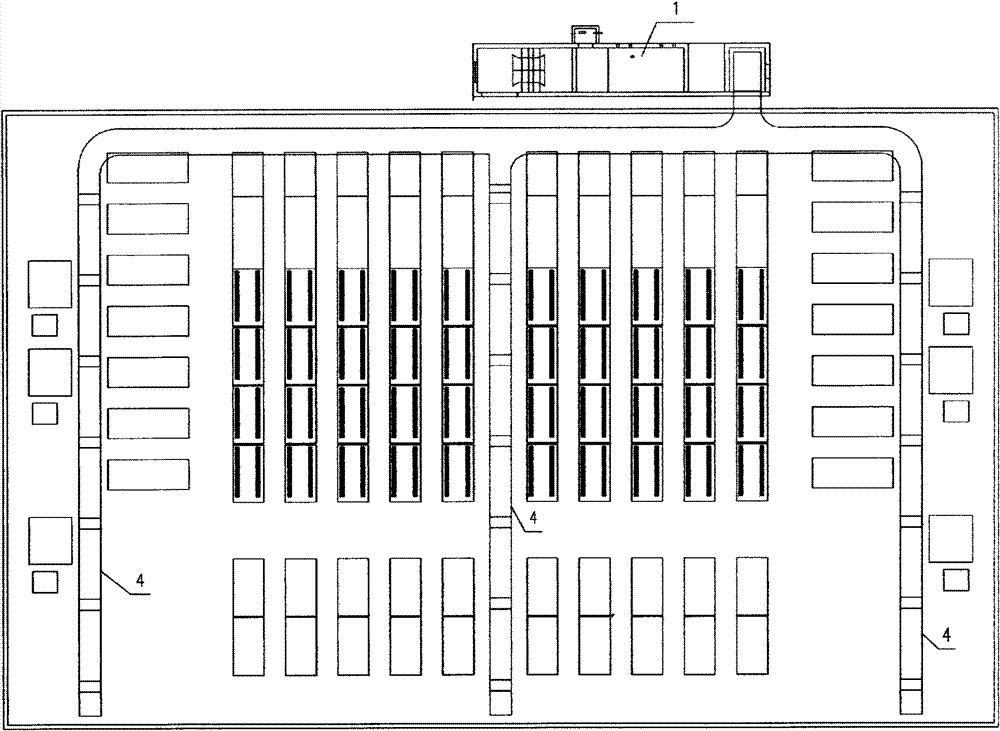

[0042] refer to Figure 1-Figure 5 , the direct evaporative temperature-humidity exchange air-conditioning system of the present invention comprises the air-conditioning room 1 made up of the air supply chamber 111, the spray chamber 112 and the return air chamber 113 and the air supply pipe 2, the air supply port 106 and the upper return air pipe 3, The air supply and return system formed by the ground return air pipe 4 and the air return port 107, wherein a blower 101 is installed between the air supply chamber 111 and the spray chamber 112 (the air volume is calculated as the number of air changes is not greater than 8 times per hour), In the spray room, respectively install water baffles 102, one or two groups of controllable spray pipes 103, and install 2 to 3 rows of nozzles 104 in each group, and the number of nozzles is 3-5 per m 2 The air supply chamber 111 sends wet and cold air into the work area through the air supply pipe 2 and the air supply port 106 located at t...

Embodiment 2

[0044] A cut-off valve 6 and an exhaust valve 7 are arranged between the upper return air pipe 3 and the return air chamber. In summer, the stop valve 6 can be closed and the exhaust valve 7 can be opened to discharge hot air; in winter, the exhaust valve 7 can be closed. Open the cut-off valve 6 to allow hot air to enter the return air chamber 113, so as to make full use of the original waste heat, thereby omitting the heater in the traditional air-conditioning system, and improving the energy-saving efficiency of the air-conditioning system. A blower fan 5 is arranged in the air supply pipe 2 or the air return pipe 3, which can be opened as required to facilitate normal work in high temperature climates. The feng-shui ratio is appropriate, and the circulating water does not heat up, thus achieving the purpose of water saving. The air supply outlet is preferably located above the working area of the equipment, so that the wet and cold air can exchange temperature and humidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com