Hydroenergy impactor

A technology of impactor and water energy, applied in the field of impact tools, can solve the problems of no lubrication system, waste of energy, increase of cost, etc., and achieve the effect of solving power waste and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

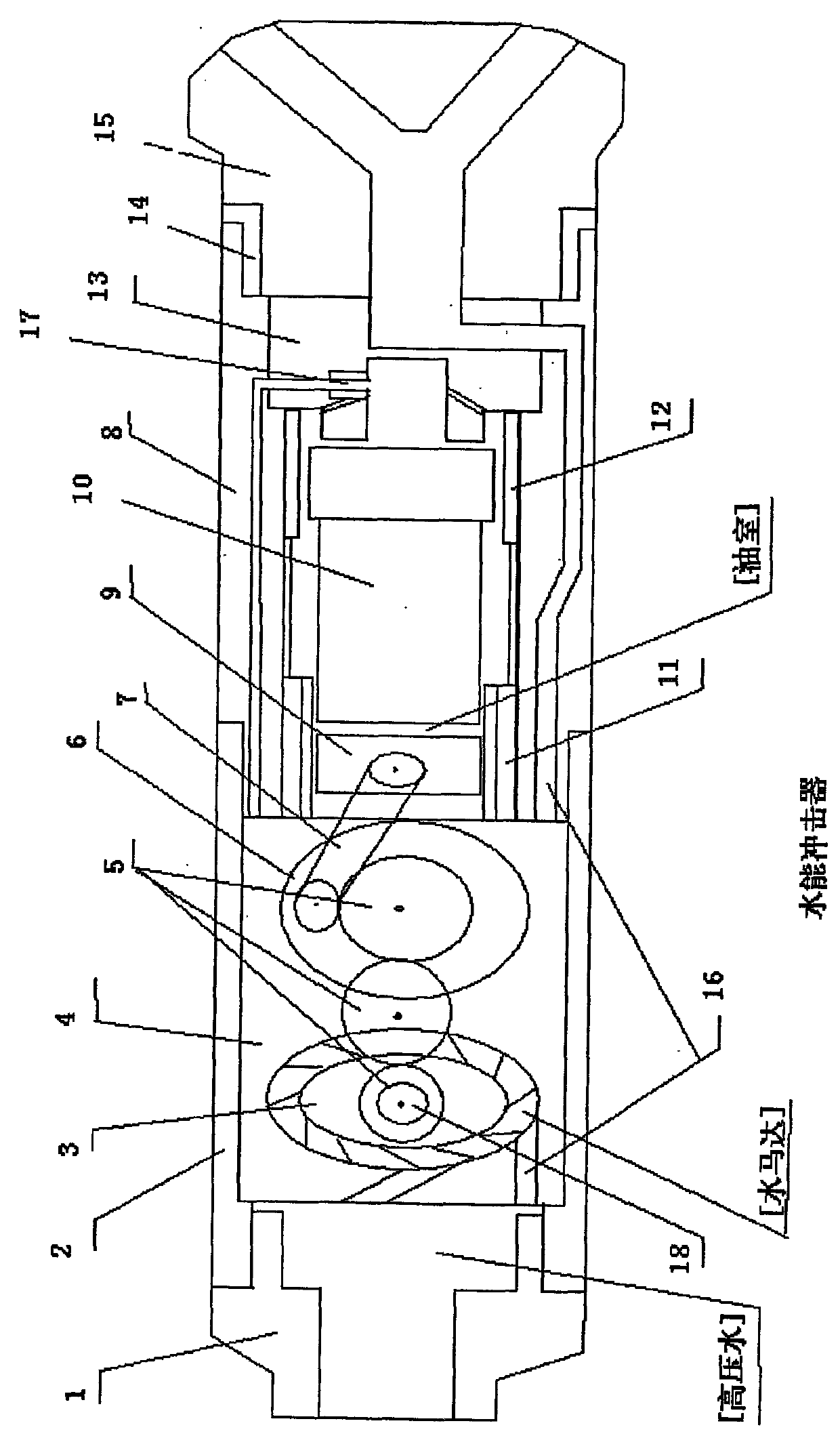

[0009] In summary, the present invention discloses a water energy impactor such as figure 1 , including 1 front joint, 2 outer casing, 3 impeller, 4 inner body, 5 gear, 6 crankshaft, 7 connecting rod, 8 outer body, 9 piston, 10 impact hammer, 11 upper cylinder liner, 12 lower cylinder liner, 13 lower Sit. 14 Lower joint. 15 Drill bit. 16 Waterway system. 17 Lubricating system. 18 Sealing system. It is characterized in that the high-pressure water pushes the impeller through the high-pressure holes of the inner body at different angles to make it rotate at a high speed of 1500 rpm, and is discharged from the water channel. Two alloy sealing rings are installed on the impeller shaft to achieve the purpose of water and oil separation. The gear is transmitted to the crankshaft, connecting rod, piston, oil chamber, and hammer to achieve the purpose of high-frequency impact, and the oil hole in the middle of the oil groove around the low seat, the check valve, and the oil reaches th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com