Newly Filled Sludge Foundation Treatment Method

A technology for foundation treatment and dredging of silt, which is applied in the field of building foundations, can solve problems such as the difficulty in guaranteeing the effect of foundation treatment, the difficulty in allocating resources, and the disturbance and damage of the hard crust on the surface, so as to achieve good foundation treatment effect and shorten the growth time , the effect of shortening the drainage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A dredging mud foundation treatment method, comprising three stages of shallow vacuum dewatering combined with preloading, vacuum combined with surcharged preloading and composite foundation, characterized in that the following steps are carried out in sequence:

[0054] During vacuum preloading, foundation treatment shall be carried out as follows:

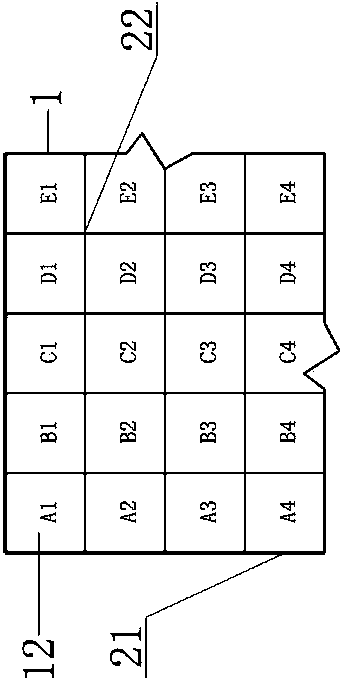

[0055] a. Partition: partition the area to be processed 1, such as figure 1 As shown, the area of each partition unit 11 is 10000m 2 ~20000m 2 , erect floating bridge 22 between partition unit 11;

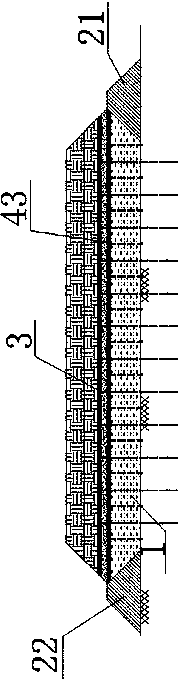

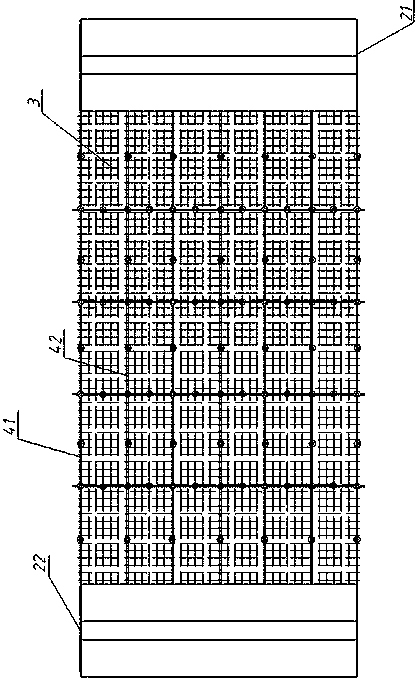

[0056] b. Lay shallow vacuum dewatering combined with preloaded cushion:

[0057] On the land, the corrugated seepage pipes 41 form a criss-cross network structure in the horizontal direction, and the intersections of the corrugated seepage pipes 41 are connected with two-way elbows or three-way joints. The diameter of the corrugated seepage pipes 41 is 50 mm to 70 mm. The distance between adjacent corrugated seepage pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com