Dyeing method of cellulosic fiber fabric

A technology of cellulose fiber and dyeing method, which is applied in the field of dyeing of cellulose fiber fabrics, can solve the problems of poor soaping fastness and low dyeing rate, and achieve the effects of low production cost, simple process flow and improved adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

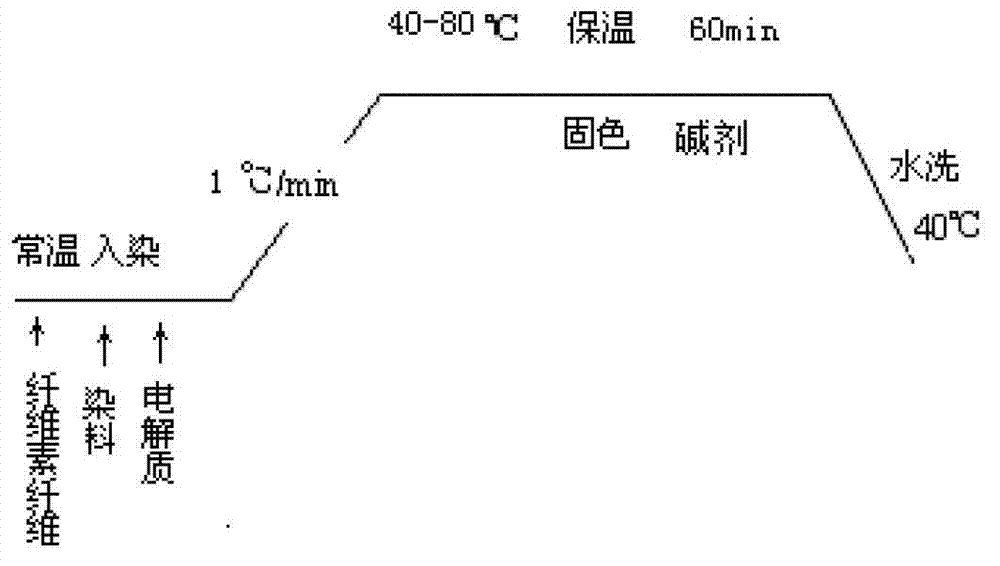

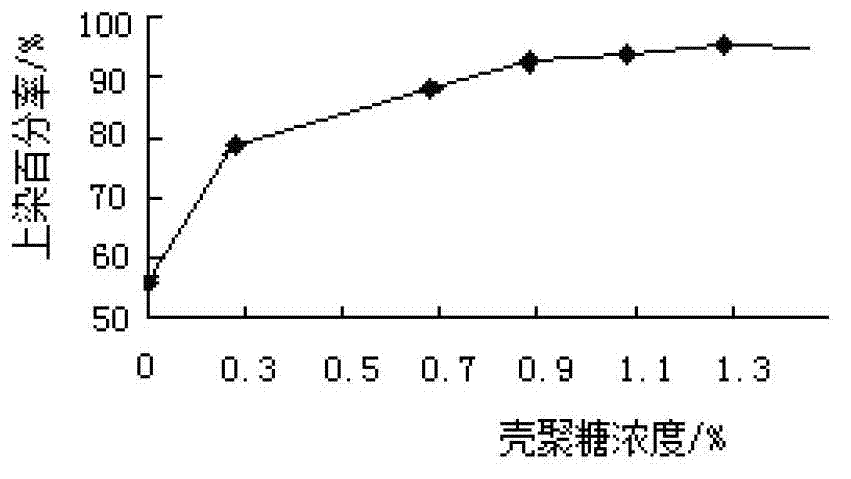

[0038] The chitosan solution that mass fraction is respectively 0.4%, 0.8%, 1.2%, is processed fabric by the method for step 1 respectively, then by the reactive dye dyeing method in step 2 and step 3, the fabric after processing is dyed, dyeing Process reference figure 1 , the fabric after dyeing is carried out dyeing performance test, and test result, when chitosan mass fraction is 0.4%, 0.8%, 1.2%, K / S value is respectively 18.5, 21.2, 22.3, it can be known that when chitosan When the mass fraction is about 0.8%, the fabric has the best dyeing depth.

Embodiment 2

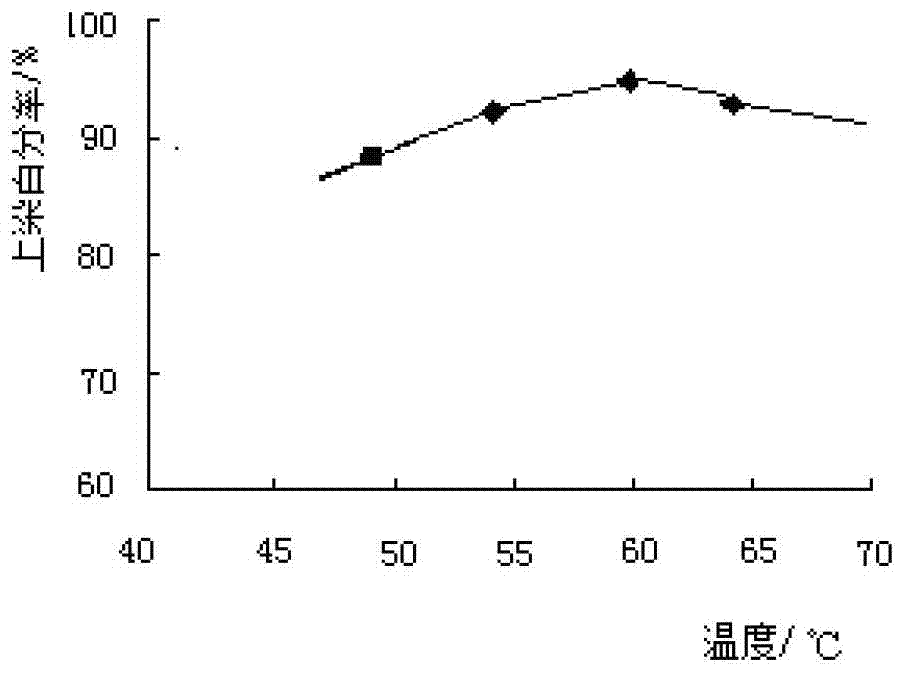

[0040] When the chitosan solution with a mass fraction of 0.8% is at 40°C, 60°C, and 80°C, the fabric is treated according to the method of step 1, and then the treated fabric is dyed according to the reactive dye method in step 2 and step 3. The fabric is dyed, and the dyeing process refers to figure 1 , the dyed fabric was tested for dyeing performance. The test results showed that when the chitosan pretreatment temperature was 40°C, 60°C, and 80°C, the K / S values were 19.8, 23.1, and 22.8. It can be seen that when the chitosan When the pretreatment temperature of polysaccharide is about 60℃, the deep dyeing property of the fabric is the best.

Embodiment 3

[0042] With a chitosan solution with a mass fraction of 0.8%, the temperature is 60°C, when the pretreatment temperature is 8min, 16min, and 24min respectively, the fabric is treated according to the method of step 1, and then dyed with reactive dyes in step 2 and step 3 The method is to dye the treated fabric, and the dyeing process refers to figure 1, the fabric after dyeing is carried out dyeing performance test, test result, when chitosan pretreatment time is respectively 8min, 16min, 24min when K / S value is respectively 18.9, 22.7, 22.1, it can be known that when chitosan pretreatment When the treatment time is about 16 minutes, the deepness of the fabric is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com