Dye and method for dyeing and finishing polyester fabric by using same

A dye and polyester technology, applied in the dyeing field of polyester fabrics, can solve the problems of poor color migration of related fastness PVC, unsatisfactory moisture absorption and decontamination ability, etc. Fastness, related fastness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0017] 1. Dyes and dyeing and finishing methods

[0018] A kind of dyestuff of the present invention, comprises following raw material: Disperse dye FW-N violet 0.8%owf, HAC 0.5g / L, disperse leveling agent 0.5g / L, moisture-absorbing perspiration easy decontamination agent FC226 1.5g / L, degreasing Agent 1.0g / L, acid reducing cleaning agent 3.0g / L and anti-ultraviolet shielding agent 10g / L. Among the present invention, the disperse dye FW-N purple is purchased from Quanzhou Modern Dyestuff Chemical Co., Ltd., and the moisture-absorbing perspiration and easy decontamination agent FC226 is purchased from the U.S. 3M company. In addition, disperse leveling agent, degreaser, acid reduction cleaning agent and All the anti-ultraviolet shielding agents are commercially available.

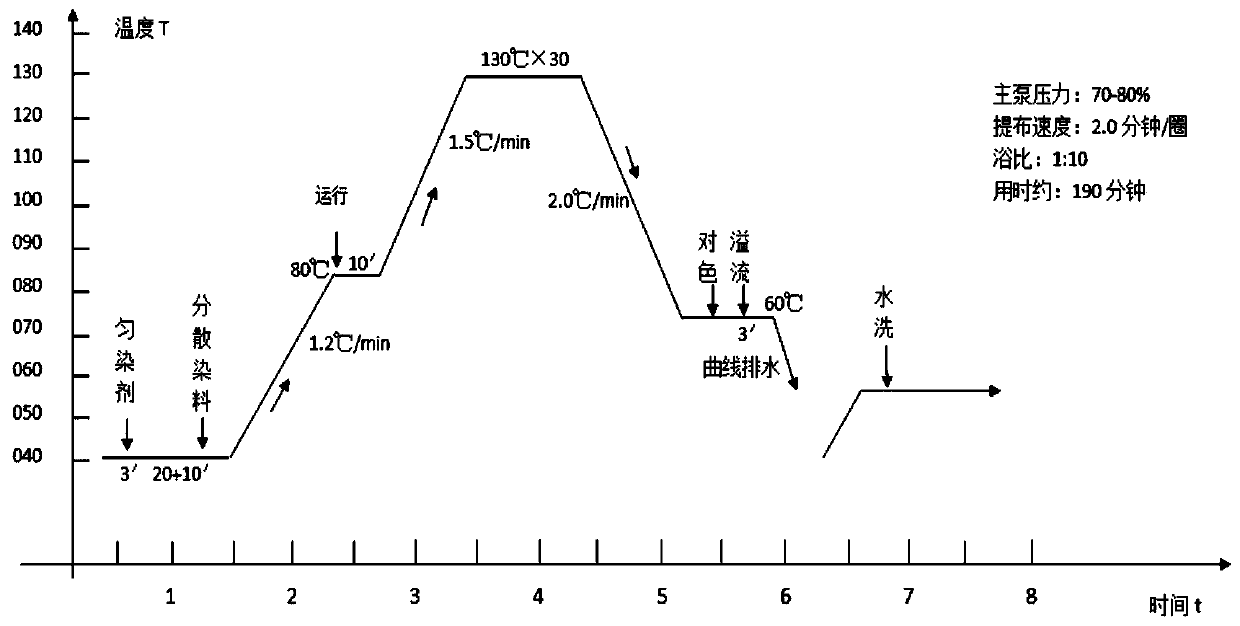

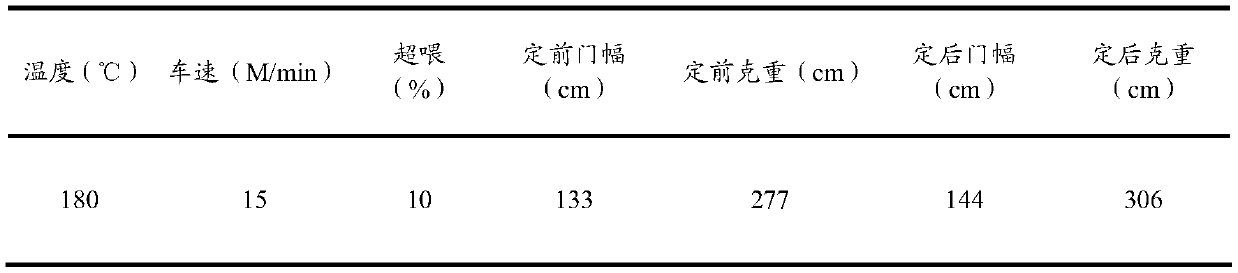

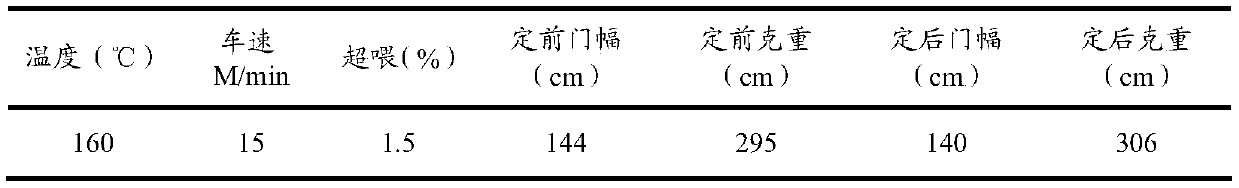

[0019] A dyeing and finishing method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com