Nuclear power plant ring crane corbel and manufacturing method thereof

A nuclear power plant and ring-hoisting technology, which is applied to manufacturing tools, load-hoisting components, and hoisting equipment braking devices, etc., can solve the problems of high degree of restraint, easy cracks in welding seams, and harsh environment, so as to compensate for welding deformation and speed up The construction process and the effect of ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

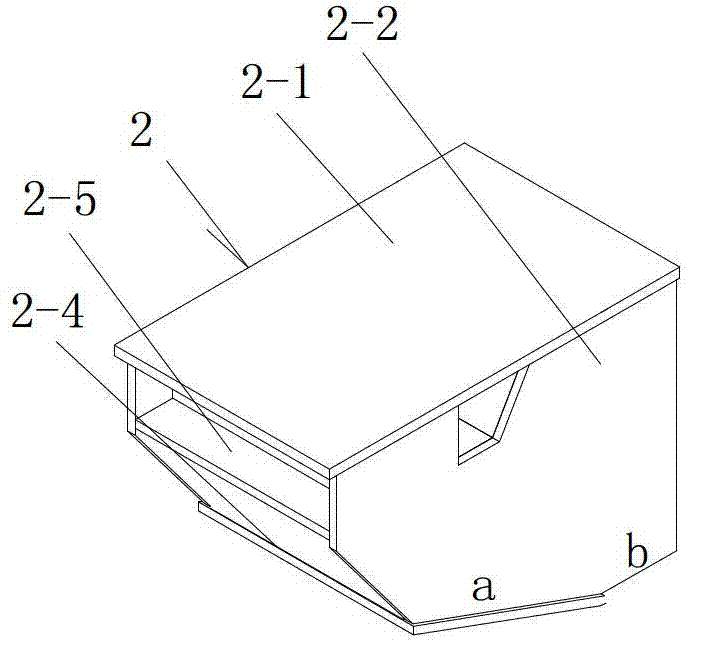

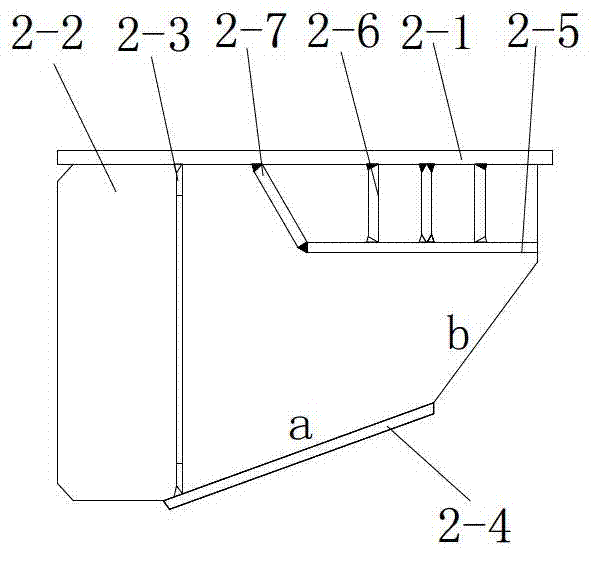

[0024] The ring hanging corbel of the nuclear power plant in this embodiment is designed through a combination of estimation and experimentation, and is composed of a back stiffener 1, a load-bearing box 2 extending forward from the front of the back stiffener, a reinforcing plate, and a sealing plate (see Figure 4 ).

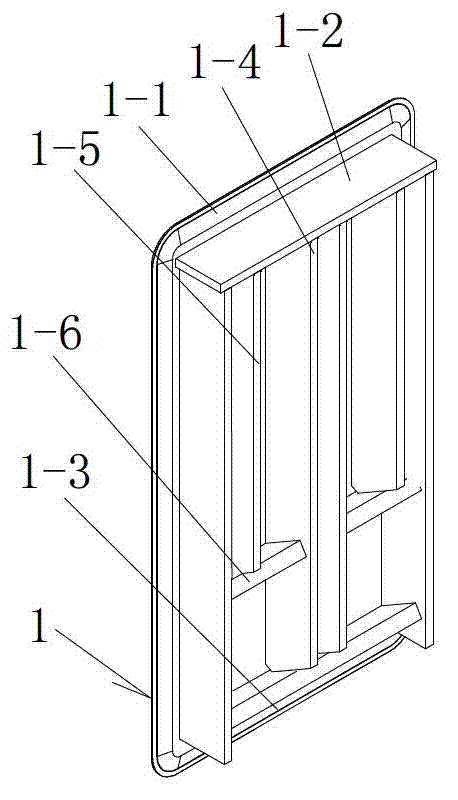

[0025] The specific structure of the back stiffener 1 is as follows: figure 1 As shown, it is composed of a vertical main board 1-1 welded to a fixed rib on the back. The reinforcement plate includes a door frame 1-2, a horizontal main reinforcement 1-3 located at the lower part of the door frame 1-2, two vertical main reinforcements 1-4 at intervals in the middle of the door frame, and a vertical central reinforcement 1-4 And the two vertical auxiliary ribs 1-5 between the two sides of the door frame 1-2, and the two horizontal auxiliary ribs 1-6 respectively located at the lower ends of the two vertical auxiliary ribs 1-5 corresponding to the middle part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com