Easy-joint PVC (polyvinyl chloride)-core polyvinyl chloride conveying belt and preparation method thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, applied in the direction of conveyors, transportation, packaging, coating, etc., can solve the problems of increasing use cost and difficulty, affecting the working state and service life of the conveyor belt, and improving production Operational Efficiency, Avoidance of Large Expenses, Effect of Avoidance of Processing Fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Easy joint PVC core polyvinyl chloride conveyor belt

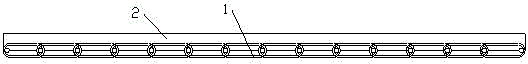

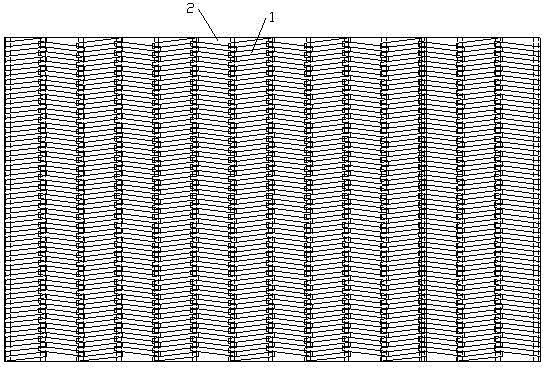

[0033] see Figure 1-2 The shown easy-joint PVC core polyvinyl chloride conveyor belt includes a ring-type PVC core skeleton 1 and a polyvinyl chloride resin coating layer (covering layer) 2 coated on the upper surface of the ring-type PVC core skeleton.

[0034] The ring-type PVC core skeleton is composed of PVC straight cores 3 and PVC winding cores 4; there are more than three PVC straight cores arranged in parallel and at intervals. Between two adjacent PVC straight cores, there is a PVC winding core that spirally bypasses adjacent two PVC straight cores; two PVC winding cores wound on the same PVC straight core The cores are spaced apart in the axial direction. see Figure 4 , the helical directions of two PVC winding cores wound on the same PVC straight strip core are opposite. see Figure 5Looking at a PVC winding core from the axial direction of the PVC straight strip core, the PVC winding co...

Embodiment 2

[0036] Embodiment 2: the preparation of easy joint PVC core polyvinyl chloride conveyor belt

[0037] The preparation process of this easy-joint PVC core polyvinyl chloride conveyor belt, see the flow chart Figure 6 As shown, it mainly includes the following steps:

[0038] (1) Preparation of ring-type PVC core skeleton

[0039] Ring buckle PVC core skeleton structure such as Figure 4-5 As shown, there are PVC winding core a, PVC winding core b (the PVC winding core is divided into a and b for the convenience of expression, the diameter of the PVC winding core is about 0.8mm) and PVC straight core 3 (the diameter is about 1mm) composition. Among them, PVC winding core a is coiled clockwise on two adjacent PVC straight cores from bottom to top to form a chain, and PVC winding core b is counterclockwise on two adjacent PVC straight cores from bottom to top. Winding into a chain shape, PVC winding core a and PVC winding core b are interspersed at intervals of each circle, P...

Embodiment 3

[0046] Embodiment 3: the joint method of easy joint PVC core polyvinyl chloride conveyor belt

[0047] The joint process is greatly simplified by using the ring-type PVC core skeleton instead of the conventional fabric core skeleton. The specific joint method is described as follows:

[0048] (1) End cutting

[0049] Determine the length and width of the conveyor belt to be used according to the requirements of the actual assembly line equipment, and cut it accurately, such as Figure 7 , 8 As shown, the two ends 5 and 6 that need to be butted in the length direction of the conveyor belt are cut along the outer edge of the winding core, and the ends of the winding core are kept intact.

[0050] Pull out the PVC straight strip core on the cut end to get the conveyor belt end without PVC straight strip core fixed, such as Figure 9 , 10 shown.

[0051] (2) Soften stitching

[0052] Such as Figure 11 , 12 As shown, heat the two ends of the conveyor belt with the PVC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com