A foam tube extrusion die with adjustable feed flow rate

A technology of feed flow and extrusion mold, which is applied in the field of molds for manufacturing plastic pipes, can solve the problems of invariable position and poor controllability of slurry flow, and achieve the effects of ensuring stability, facilitating flexible control, and ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

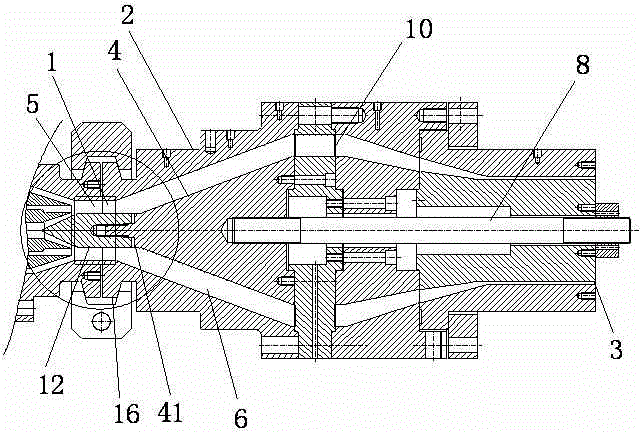

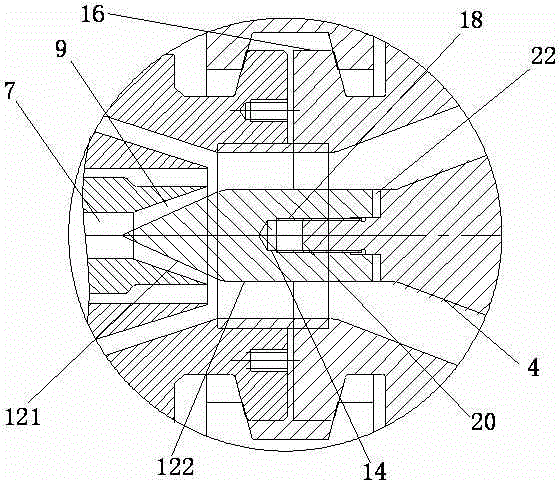

[0017] Embodiment 1: as Figure 1-2 As shown, a foam tube extrusion die with adjustable feed flow rate of the present invention includes a cylindrical die 2 extending transversely and a cylindrical mandrel 4 arranged in the die, between the die 2 and the mandrel 4 The tubular gap between them becomes the slurry channel 6, the axis of the mandrel 4 is provided with a mandrel 8 extending transversely, and the axial middle part is provided with a columnar support rod 10 connecting the mandrel 8 and the outer wall of the die 2, and the extrusion die The two ends in the transverse direction are the inlet port 1 and the outlet port 3 respectively. At the inlet port 1, the mandrel 4 is provided with a regulator 12 whose head is tapered and whose axial distance relative to the mandrel 4 is adjustable. The regulator 12 is connected to the mandrel 4 through screws 14, with the head facing outwards. The inlet end 1 is provided with a flange 16 for connecting with the feeding mold. Alon...

Embodiment 2

[0018] Embodiment 2 (not shown): The difference from Embodiment 1 is that the screws 14 are located along the radial direction of the mandrel 4, and the protrusions 20 of the mandrel 4 are provided with 3-4 axially located at different positions. The screw holes 24 are matched with the screws 14 respectively. When in use, the axial distance of the regulator 12 relative to the outlet end 3 of the feed mold is changed by inserting the screw 14 into different screw holes 24 .

[0019] When manufacturing the foam tube, the inlet end 1 of the extrusion die and the outlet end 5 of the feed die are connected through a flange, and the head 121 of the regulator 12 is inserted into the inner passage 7 of the feed die. Since the two ends of the usual inner passage 7 are Trumpet-shaped, so that the regulator head 121 is specifically inserted into the horn-shaped part 9 of the inner channel close to the outlet end 5 of the feed mould. Change the distance of the adjuster head 121 relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com