Rapid locking mechanism for stirring paddle

A locking mechanism and stirring paddle technology, applied in mixer accessories, mixers, dissolving and other directions, can solve the problems of inconvenient and quick disassembly, unable to achieve fast locking installation and disassembly, etc., to achieve convenient processing, reduce machine downtime, improve The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

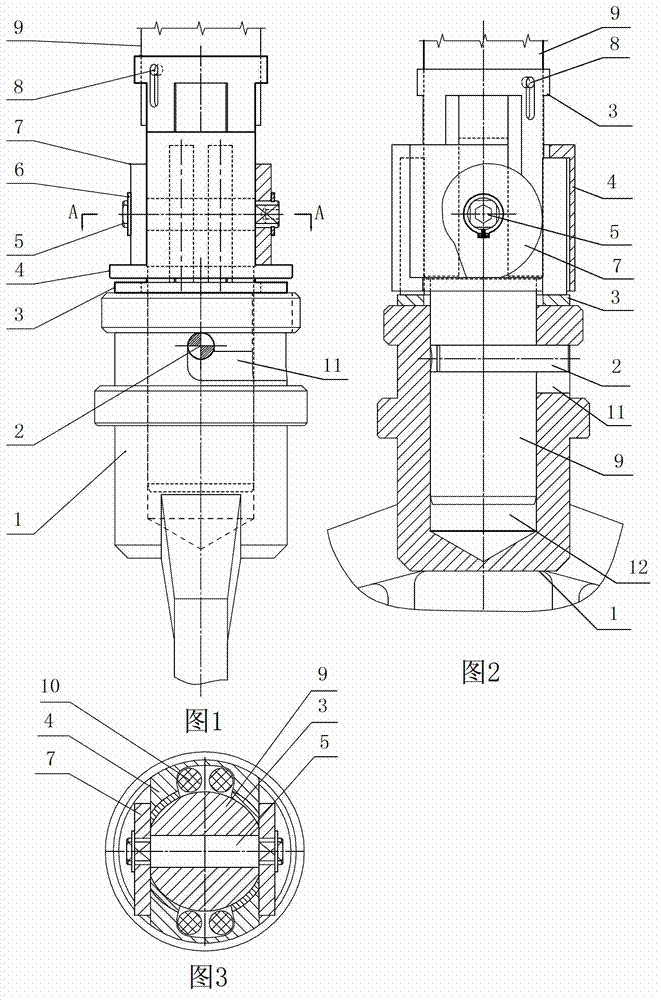

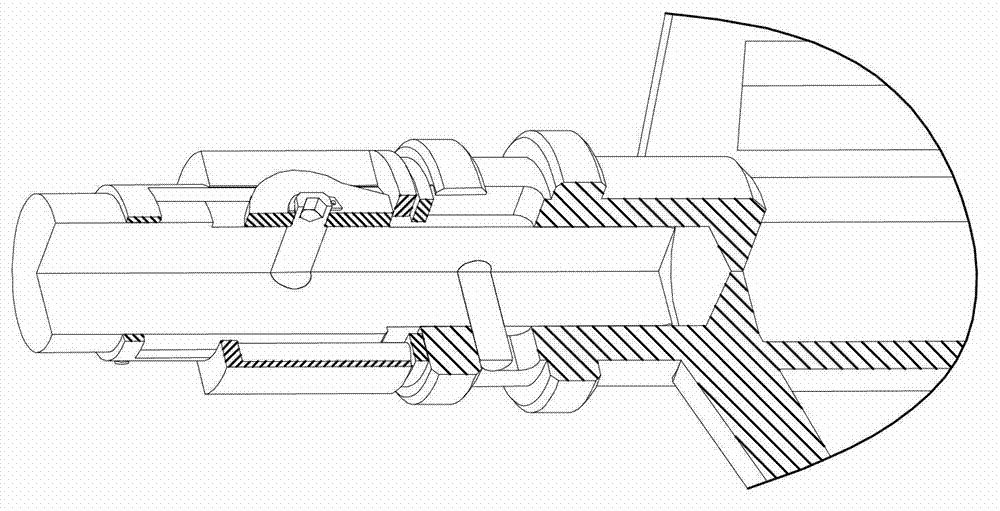

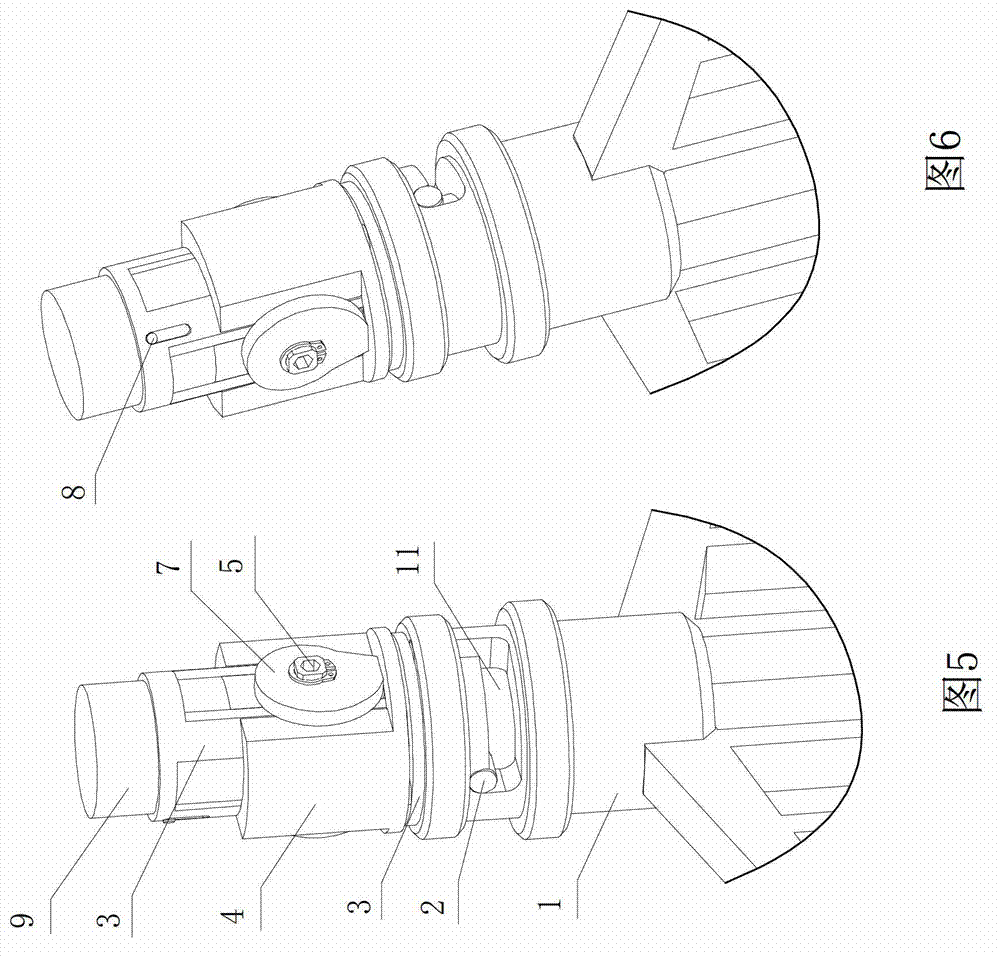

[0035] Embodiment 1: A quick locking mechanism for stirring paddles, such as Figure 1 to Figure 6 As shown, it includes a stirring shaft 9, a stirring paddle 1 with a stirring shaft installation groove 12 on the top, a pressure sleeve 3, a rubber strip holding sleeve 4, a rubber strip 10 and two cams 7, and the stirring shaft 9 is provided with a drive Pin hole 93, driving pin 2 is fixedly installed in the driving pin hole, camshaft installation hole 92 is provided on the stirring shaft above the driving pin hole, and a mirror with the straight line of the vertical horizontal line as the axis is provided on the described stirring paddle 1. L-shaped groove 11, the groove is simple and suitable for processing, the stirring shaft 9 is installed in the stirring shaft installation groove 12 of the stirring paddle 1, and in the locked state, the driving pin 2 on the stirring shaft is located in the mirror direction L of the paddle In the position 111 at the end of the type groove (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com