Heat-conductive Elastomer Composition

A technology of thermal conductivity and composition, applied in the direction of semiconductor devices, electric solid-state devices, electrical components, etc., can solve the problems of poor formability, hard composition, and inability to use tungsten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~25

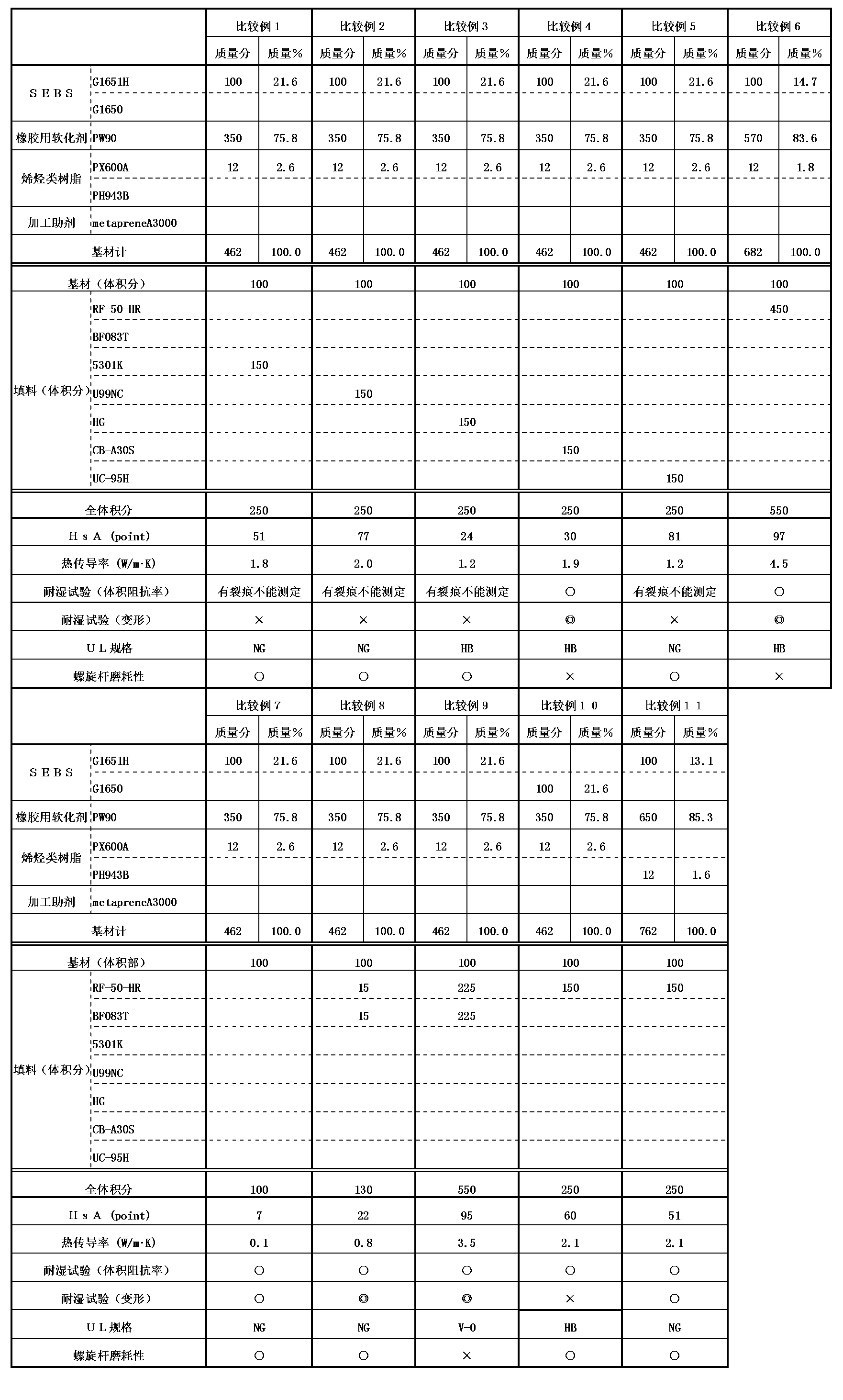

[0093] (Examples 1-25, Comparative Examples 1-11)

[0094] (Material)

[0095] The materials described below were used.

[0096] 1. Hydrogenated thermoplastic styrene elastomer (SEBS)

[0097] (1) G11651 (trade name, manufactured by Karton Performance Polymers Co., Ltd. (Karton Performance Polymers Co., Ltd)) content of styrene monomer: 33%, Mw: 290,000, 1,2-ethylene bonded amount: 37% by mass)

[0098] (2) MD1633 (trade name, manufactured by Karton Performance Polymers Co., Ltd. (Karton Performance Polymers Co., Ltd)) content of styrene monomer: 33%, Mw: 450,000, 1,2-ethylene bonded amount: 37% by mass)

[0099] (3) G1650 (trade name, manufactured by Karton Performance Polymers Co., Ltd. (Karton Performance Polymers Co., Ltd)) content of styrene monomer: 29%, Mw: 110,000, 1,2-ethylene bonded amount: 37% by mass)

[0100] 2. Rubber softener

[0101] (1) PW90 (trade name, manufactured by Idemitsu Kosan Co., Ltd.) Dynamic viscosity (40°C): 84.0cSt

[0102] (2) PW90 (trad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com