A series topology LED switching power supply circuit

A switching power supply circuit and topology technology, applied in electrical components, regulating electrical variables, instruments, etc., to achieve the effects of easy EMI suppression, simple structure, and high operating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

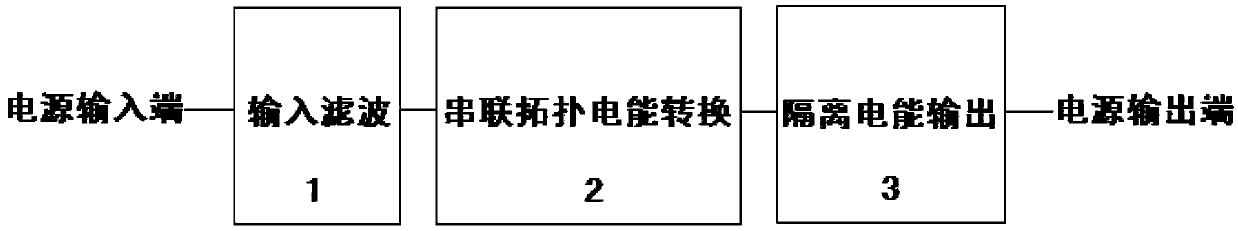

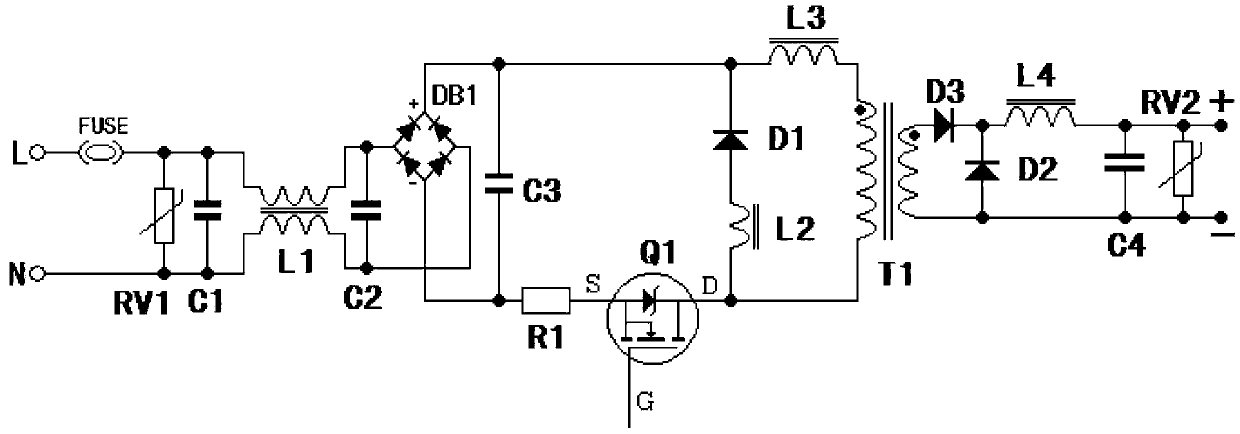

[0036] like Figure 1~3 As shown, a series topology LED switching power supply circuit includes a power supply input terminal, an input filter 1, a series topology power conversion 2, an isolated power output 3, and a power supply output terminal sequentially connected in series. Among them, L and N are the power input, RV1 is an overvoltage protection tube connected in parallel to the power input terminals L and N, the input filter 1 is composed of storage RV1, capacitor C1, common mode inductor L1, and capacitor C2, and the series topology power conversion 2 It is composed of rectifier circuit DB1, capacitor C3, energy storage inductor L3, transformer T1, inductor L2, diode D1, switch tube Q1, and resistor R1. The rectifier circuit DB1 provides directional AC output power. Capacitor C3 is connected in parallel to the directional rectifier circuit DB1. The AC zero-crossing compensation is performed on the output circuit end, the directional current output positive end of the ...

Embodiment 2

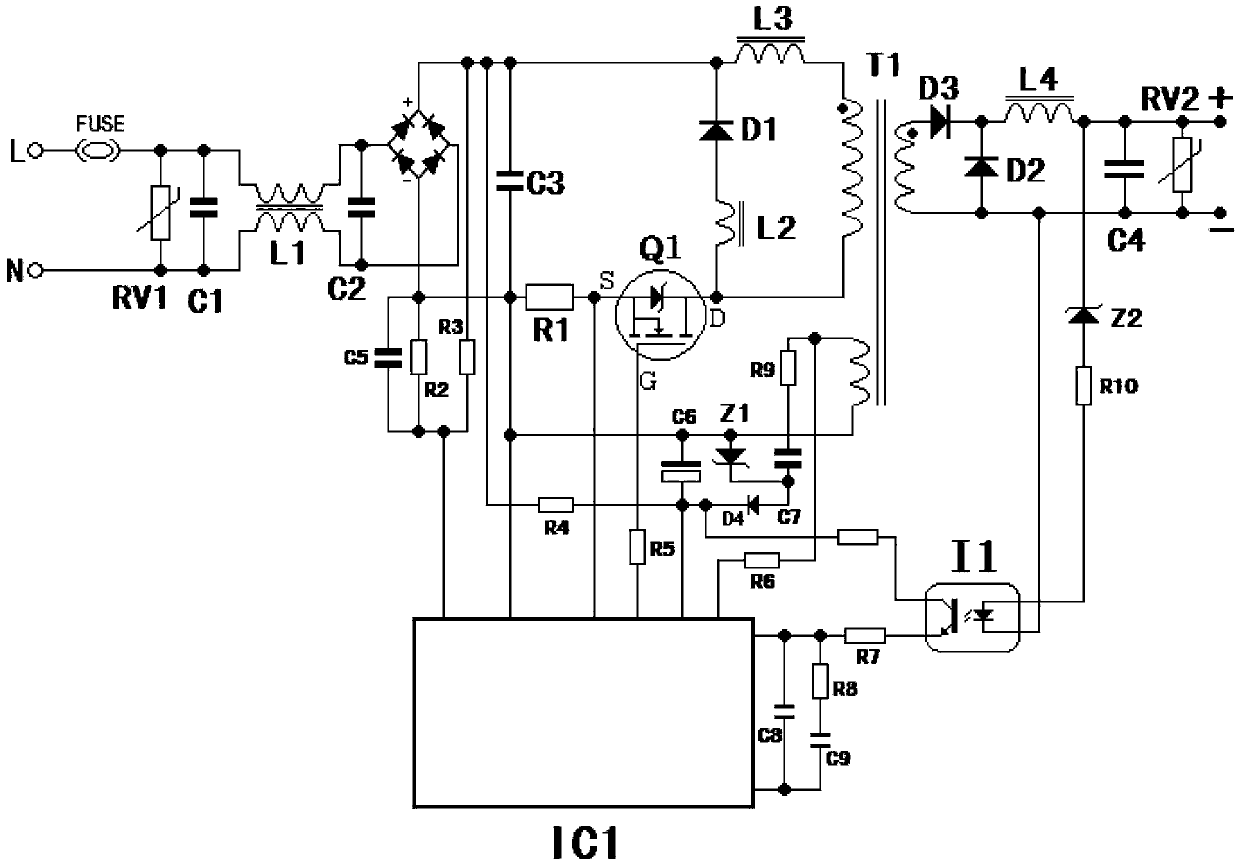

[0042] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment adopts the upper drive mode, a series topology LED switching power supply circuit, the circuit includes L and N as the power input, and RV1 is connected in parallel at the power input terminals L and N The overvoltage protection tube, capacitor C1, common mode inductor L1, and capacitor C2 form an input EMI filter circuit. The rectifier circuit DB1 provides directional AC output power. Capacitor C3 is connected in parallel to the directional output loop end of the rectifier circuit DB1 for AC pass Zero compensation, the directional current output positive end of the rectifier circuit DB1 is connected to the drain D end of the switch tube Q1, the source S end of Q1 is connected to the negative end of the diode D1 and one end of the inductor L3, and the other end of the inductor L3 is connected to the transformer T1 One end of the primary winding, the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com