Reversing sheet, reverser manufactured by reversing sheet and manufacturing process of reverser

A commutator, commutator technology, applied in commutator manufacturing, current collectors, rotary current collectors, etc., can solve the problems of cumbersome production process, affecting product production efficiency, wasting manpower and financial resources, etc. The effect of simplicity, liberation of labor, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The details of its implementation will be specifically described below in conjunction with the accompanying drawings:

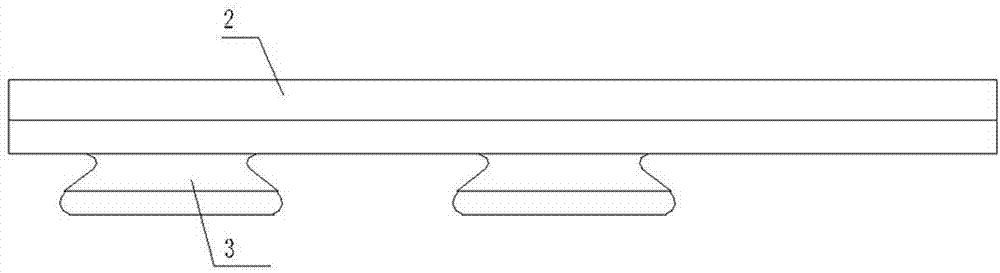

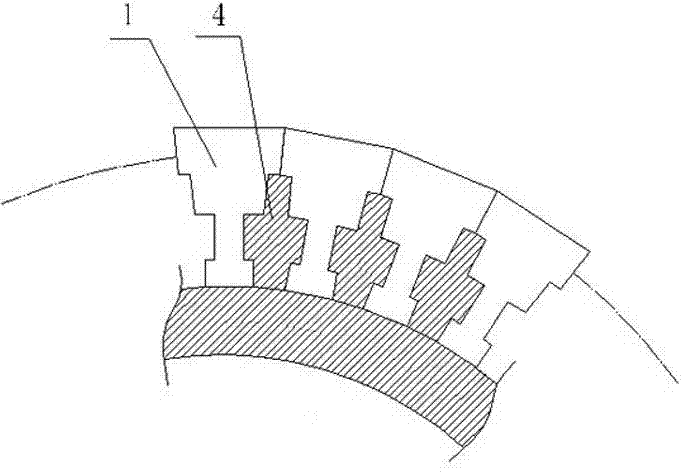

[0023] like figure 1 and 6 As shown, the present invention designs two kinds of commutator segments with different convex positions: the first commutator segment, such as figure 1 As shown, the commutator segment includes a main body 1 and a root portion 3, and the protrusions 2 are laterally arranged on both sides of the end of the main body 1. The commutator made by the commutator segment is as shown in image 3 As shown, the adjacent protrusions 2 of the commutator segments on the top are close to each other, and after the injection molding compound 4 is formed into a commutator prototype of a mica-free insert-type non-through-groove structure, a gap needs to be cut out on the protrusions when washing the tank. 6. The slot milling machine can use this gap 6 to mill slots, and customers can also mill slots on the commutator according to this gap 6;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com