Preparation method of copper interconnecting layer for improving etching appearance and reliability

A technology for copper interconnection and reliability, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. to improve the etching morphology and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

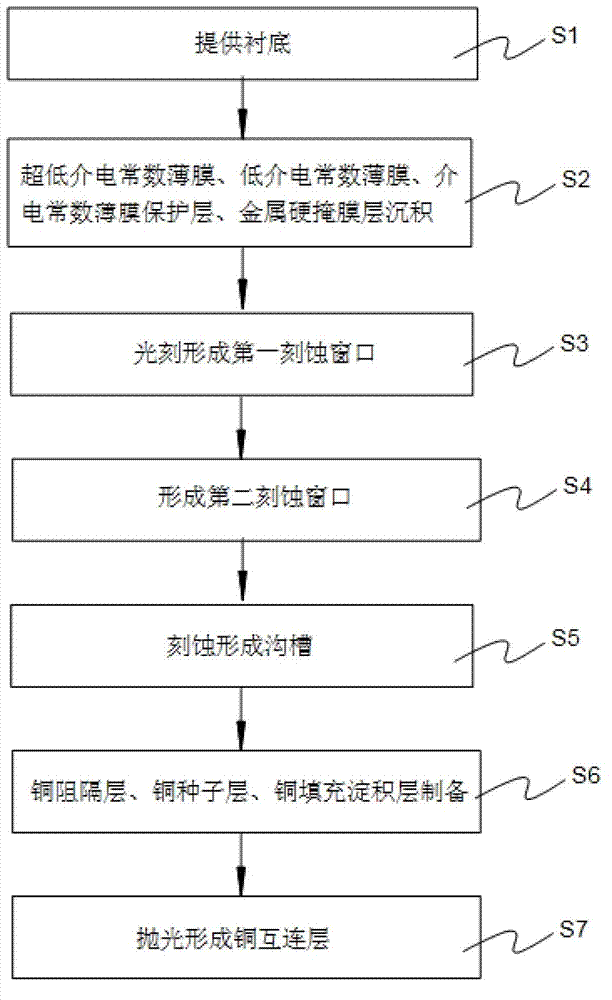

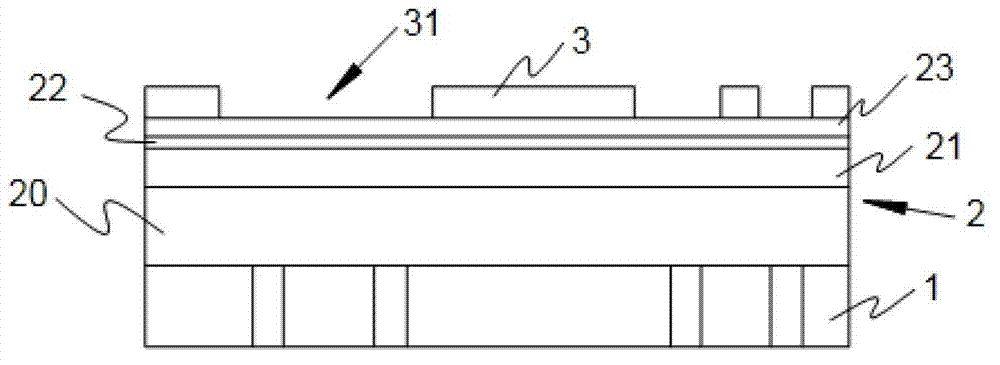

[0047] see figure 1 , figure 1 Shown is a flow chart of the copper interconnection preparation method for improving etching morphology and improving reliability of the present invention. The copper interconnect preparation method for improving etching morphology and improving reliability comprises the following steps:

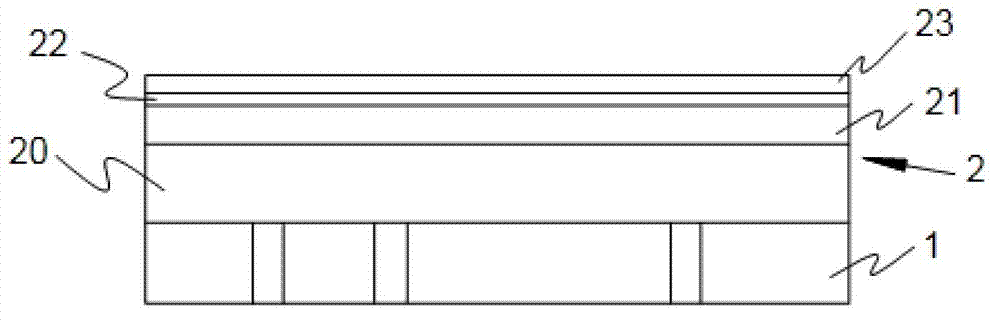

[0048]Executing step S1: providing a substrate for carrying the functional film system. For example, the functional film system sequentially includes an ultra-low dielectric constant film, a low dielectric constant film, a dielectric constant film protective layer, and a metal hard mask layer from the substrate upward;

[0049] Executing step S2: sequentially depositing an ultra-low dielectric constant film, a low di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com