Photoetching layout, photoresist graph and method for measuring exposure error of photoresist graph

A photoresist, measuring light technology, applied in microlithography exposure equipment, photolithography process exposure devices, originals for photomechanical processing, etc., can solve the problems of complex process and long test time, and simplify the test steps , the effect of saving test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

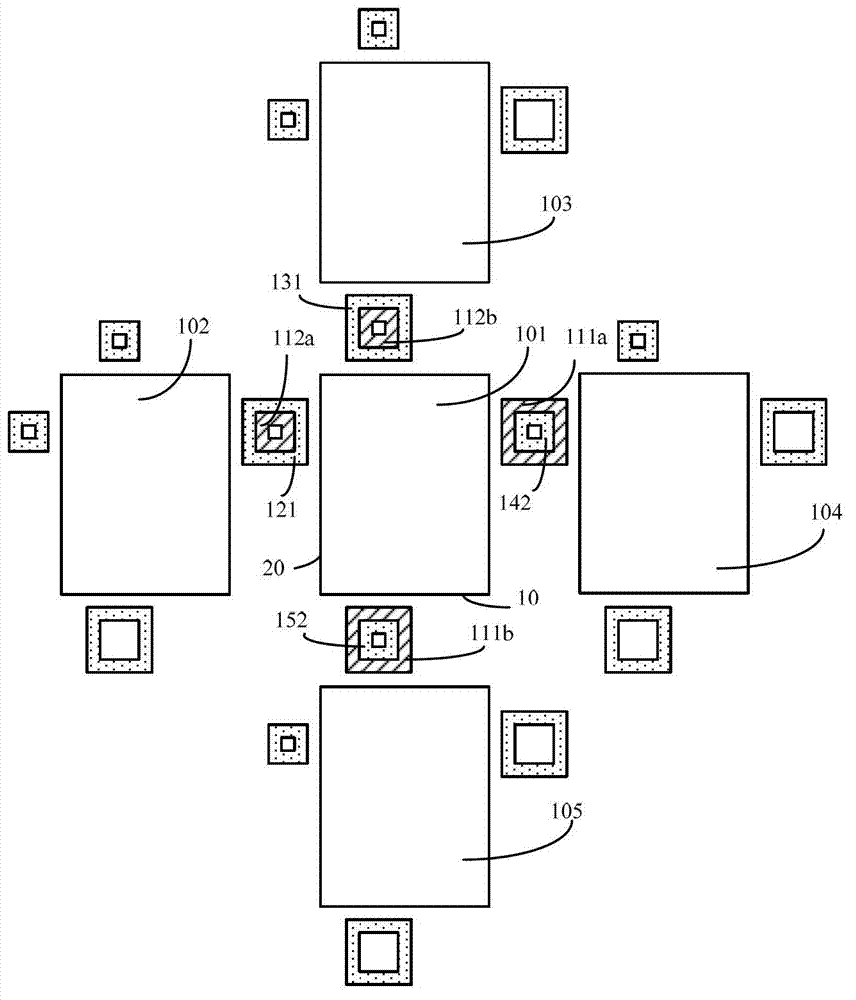

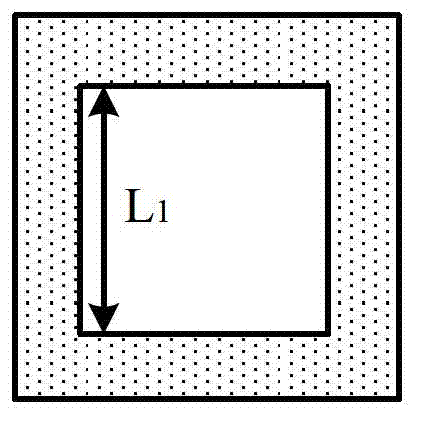

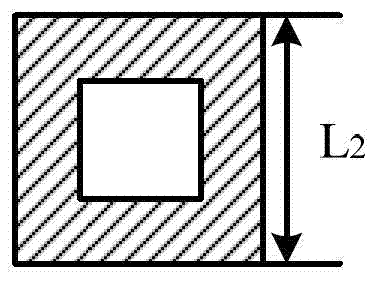

[0055] Please refer to Figure 5 , is a schematic diagram of the first embodiment of the lithographic layout of the present invention, including: a first unit area pattern 201, the first unit area pattern 201 is rectangular; four corners of the first unit area pattern 201 The first mark graphic 211a, the first mark figure 211b, the first mark figure 211c, the first mark figure 211d on the outside, the first mark figure 211a, the first mark figure 211b, the first mark figure 211c, the first mark figure 211d are all "L" shapes, and the two sides of the "L" shape are respectively parallel to the adjacent two sides constituting the top corner of the first unit area figure 201; The second marking figure 212 outside the first marking figure 211a, the second marking figure 212 is in the shape of a "ten", and the two sides forming the "ten" shape are respectively parallel to the two sides of the corresponding first marking figure 211a.

[0056] The region of the first unit area patte...

no. 2 example

[0062] Please refer to Image 6 , is a schematic diagram of the second embodiment of the photoresist pattern of the present invention, including:

[0063] The first unit area 301, the first unit area 301 is rectangular; the first mark 311a, the first mark 311b, the first mark 311c and the first mark 311d located outside the four corners of the first unit area 301, The first mark 311a, the first mark 311b, the first mark 311c and the first mark 311d are all in the shape of an "L", and the two sides of the "L" shape are respectively connected to the corners of the first unit area 301. The adjacent two sides are parallel; the second mark 312 located at a vertex of the first unit area 301 and outside the first mark 311a, the second mark 312 is a "ten" shape, and the two sides constituting the "ten" shape are respectively parallel to the two sides of the first mark 311a.

[0064] The second unit area 302, the third unit area 303 and the fourth unit area 304 arranged parallel to t...

no. 3 example

[0072] Correspondingly, the inventors of the present invention also provide a third embodiment of a method for measuring exposure errors of photoresist patterns, please refer to Figure 7 with Figure 8 , Figure 7 is the photoresist pattern used to measure the exposure error in this embodiment, Figure 8 yes Figure 7 An enlarged view of the middle area 400 .

[0073] Please refer to Figure 5 , provide a photoresist pattern, the photoresist pattern includes: a first unit area 401, a second unit area 402, a third unit area 403 and a fourth unit area 404, the first unit area 401, the second unit area Adjacent boundaries of the area 402, the third unit area 403 and the fourth unit area 404 are parallel to each other and constitute a 2×2 array of unit areas; the first unit area 401, the second unit area 402, the third unit area 403 and the Each corner of the fourth unit area 404 has a first mark on the outer side, the first mark is "L" shape, and the two sides of the "L" sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com