The protection method of optical fiber built in composite material

A composite material with built-in optical fiber technology, applied in the direction of fiber mechanical structure, can solve the problems of optical fiber damage, brittle and easy to break, etc., achieve good protection, reduce optical fiber damage rate, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

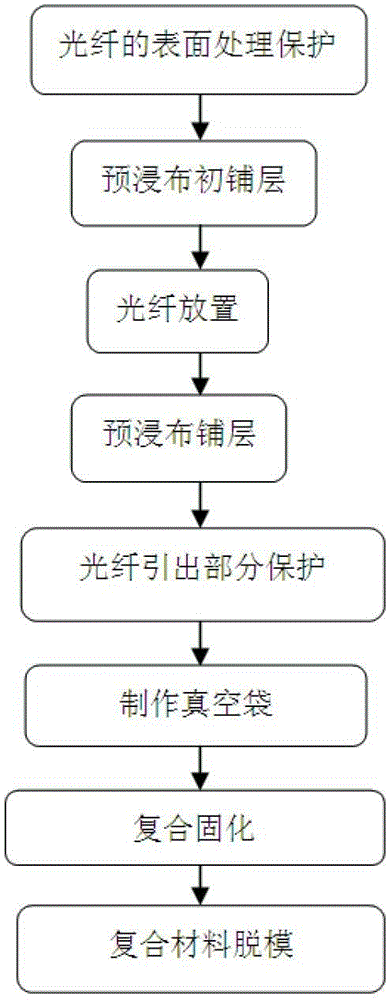

[0016] The manufacturing process of the built-in optical fiber composite material of this embodiment is as follows: figure 1 Shown: The prepreg layer of the composite material is first laid, and the optical fiber is placed on it (the inserted part of the optical fiber has been treated with surface protection), and then the prepreg layer is continued; after the layering is completed, the optical fiber part Carry out protection (cast silicone rubber after covering the demoulding step), and make a vacuum bag after curing at room temperature for 24 hours; after demoulding, the silicone rubber is demoulded, and then the composite material is demoulded.

[0017] The specific methods for the protection of the part of the inserted fiber and the part of the outgoing fiber are as follows:

[0018] 1) Insert part of the optical fiber protection:

[0019] The protection process is as follows: a layer of polymer film (acrylic film or polyimide film can be used, acrylic film is used in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com