Wind generating set flange and wear-resistant coating technology of flange

A technology for wind turbines and wear-resistant coating, applied in the field of wear-resistant coating technology, can solve the problems of poor practical operability and selectivity, the problem of surface corrosion protection has not been fundamentally solved, corrosion and other problems, and achieves cathodic protection. It has the effect of self-healing performance and excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

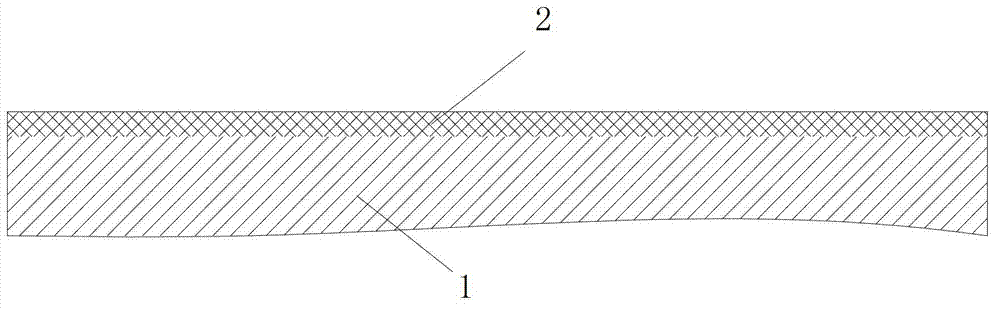

[0027] A flange of a wind power generating set includes a flange body 1, and a wear-resistant protective coating 2 formed by curing a water-based inorganic zinc-rich paint on the surface of the flange body 1. The thickness of the wear-resistant protective coating 2 is greater than or equal to 70 μm and less than or equal to 90 μm, for example, the thickness of the wear-resistant protective coating 2 is 70 μm, 80 μm or 90 μm.

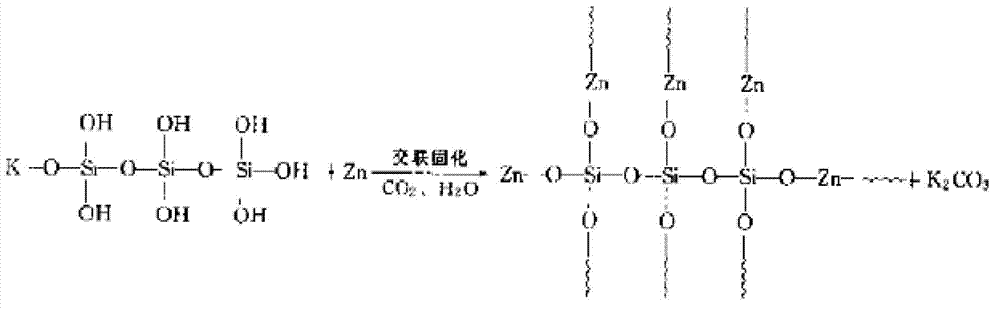

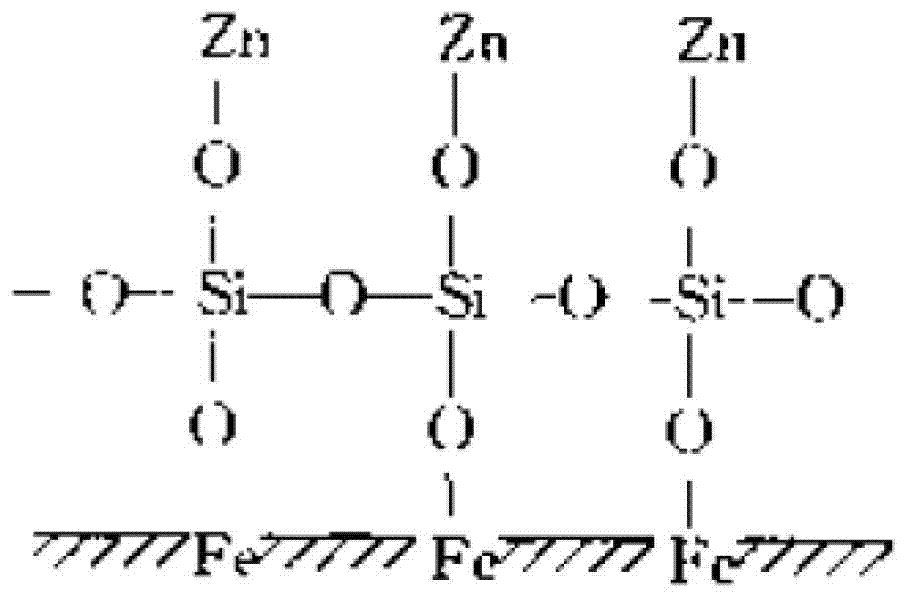

[0028] The wear-resistant protective coating 2 of the water-based inorganic zinc-rich paint (Interzinc697) forms chemical bonds with the steel surface of the flange body 1 during the curing process, and its curing mechanism is as follows figure 1 as shown,

[0029]

[0030] It can meet the technical performance requirements such as wear resistance and meshing force of the interconnected flange surfaces.

[0031] Its main technical characteristics are:

[0032] (1) High friction coefficient: The friction coefficient of the flange sprayed with water-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com