Continuous oil tube with gradually changed wall thickness and manufacturing method thereof

A manufacturing method and oil pipe technology, which is applied in the direction of drill pipe, casing, earthwork drilling, etc., can solve the problems such as large difference in performance between the weld and the base metal, failure, etc., to achieve strengthening and uniform deformation, and reduce self-weight , the effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Attached below Figure 1-2 Embodiments of the present invention are described in detail.

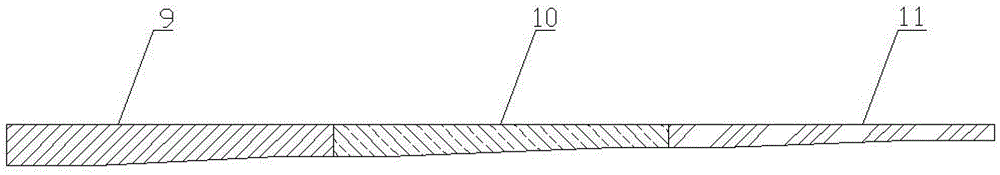

[0024] A coiled tubing with gradually changing wall thickness is formed by at least one section of wall thickness gradually changing pipe I1 and a section of wall thickness gradually changing pipe II2 butted end to end, the head end of the wall thickness gradually changing pipe I1 is a constant wall thickness joint section I3, and the middle part is a variable wall thickness Section I4, the tail end is equal-wall-thickness joint section II5; the head end of the wall-thickness gradient pipe II2 is equal-wall-thickness joint section III6, the middle part is variable-wall-thickness section II7, and the tail end is equal-wall-thickness joint section IV8; The constant wall thickness joint section II5 is docked with the constant wall thickness joint section III6, and the constant wall thickness joint section II5 has the same wall thickness as the constant wall thickness joint section II...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com