Polyvinyl chloride (PVC) composite material for Textilene cloth

A composite material, polyvinyl chloride technology, applied in the direction of yarn, textiles and papermaking, can solve the problems of unfavorable production of texlin mesh, high toxicity, etc., to improve anti-aging performance, good anti-oxidation performance, and improved anti-oxidation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

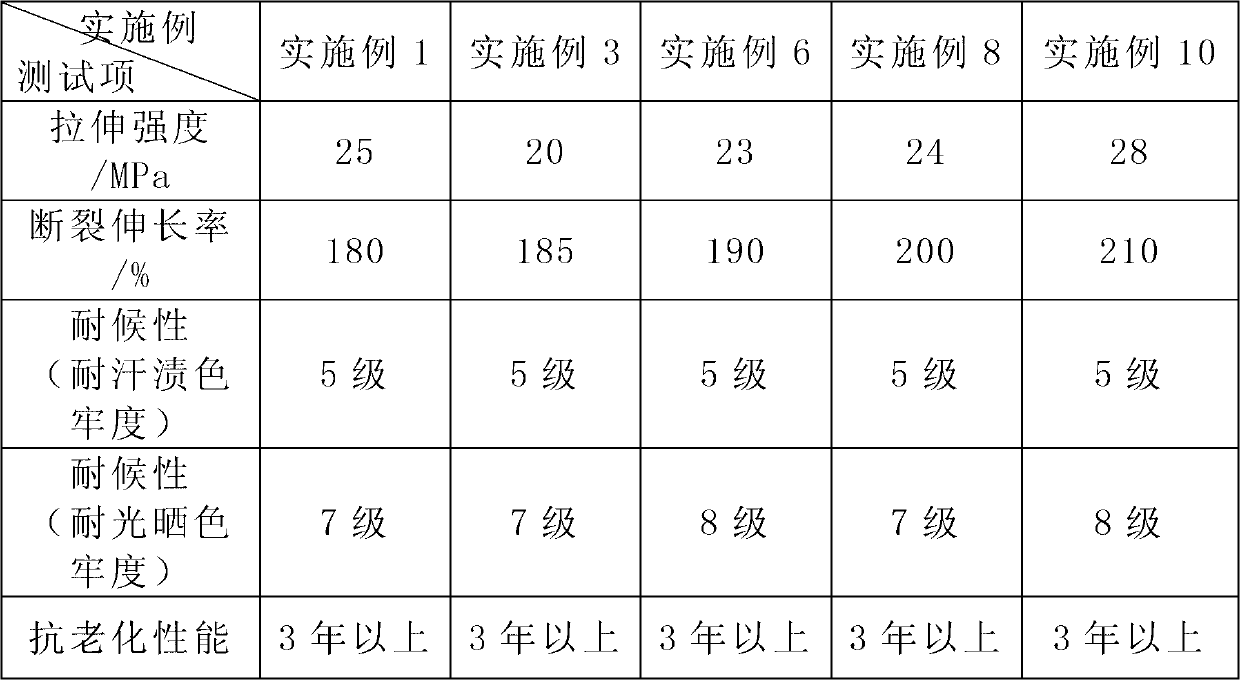

Examples

Embodiment 1

[0035] A kind of polyvinyl chloride composite material that is used for Teslin net cloth, and this composite is made up of the weight parts of following composition:

[0036] PVC: 100; Chelating agent: 2.0;

[0037] Environmentally friendly plasticizer: 20; corn starch: 10;

[0038] Flame retardant: 2.0; Weather resistance agent: 0.3;

[0039] Antioxidant: 1;

[0040] The above-mentioned chelating agent is tartaric acid; the described environment-friendly plasticizer is trimethylolpropane-tri-2-ethylhexanoate; the described antioxidant is tetrakis[β-(3,5- Di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0041] Specifically adopt the following method to prepare:

[0042]Weigh the corresponding materials according to the weight ratio of the above ingredients, first add vinyl chloride, chelating agent, environment-friendly plasticizer and antioxidant into a high-speed mixer and mix for 30 minutes at 40°C, and then Add cornstarch, flame retardant and weathe...

Embodiment 2

[0044] A kind of polyvinyl chloride composite material that is used for Teslin net cloth, and this composite is made up of the weight parts of following composition:

[0045] PVC: 100; Chelating agent: 2.5;

[0046] Environmentally friendly plasticizer: 10; corn starch: 8.0;

[0047] Flame retardant: 3.0; Weather resistance agent: 0.8;

[0048] Antioxidant: 3.0;

[0049] The chelating agent mentioned above is ethylenediamine disuccinic acid; the environment-friendly plasticizer is 2-ethylhexanoic acid-2,2-bis-(benzoylmethoxy)-butyl ester; the The antioxidant is Antioxidant 168.

[0050] The specific preparation method of the above-mentioned polyvinyl chloride composite material for Teslin mesh is consistent with the method described in Example 1.

Embodiment 3

[0052] A kind of polyvinyl chloride composite material that is used for Teslin net cloth, and this composite is made up of the weight parts of following composition:

[0053] PVC: 100; Chelating agent: 4.0;

[0054] Environmentally friendly plasticizer: 15; corn starch: 6.0;

[0055] Flame retardant: 2.5; Weather resistance agent: 1.0;

[0056] Antioxidant: 2.0;

[0057] The above-mentioned chelating agent is a mixture of ethylenediamine disuccinic acid and tartaric acid, and the weight ratio of the two is 1:2.0 between ethylenediamine disuccinic acid and tartaric acid; Hexane 1,2-diisononyl dicarboxylate; the antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and antioxidant The mixture of agent 168, the weight ratio of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester to antioxidant 168 is 1:2.

[0058] The specific preparation method of the above-mentioned polyvinyl chloride composite material f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com