Method for laterally turning heavy rack

A large-scale frame and frame technology, applied in the direction of lifting devices, etc., to achieve the effects of saving construction costs, reducing construction difficulty and risk of high-altitude operations, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] The frame overturning method disclosed in the present invention is applicable to various heavy-duty frames. In this embodiment, an elliptical die forging press frame is taken as an example, and its overturning method is carried out according to the following steps.

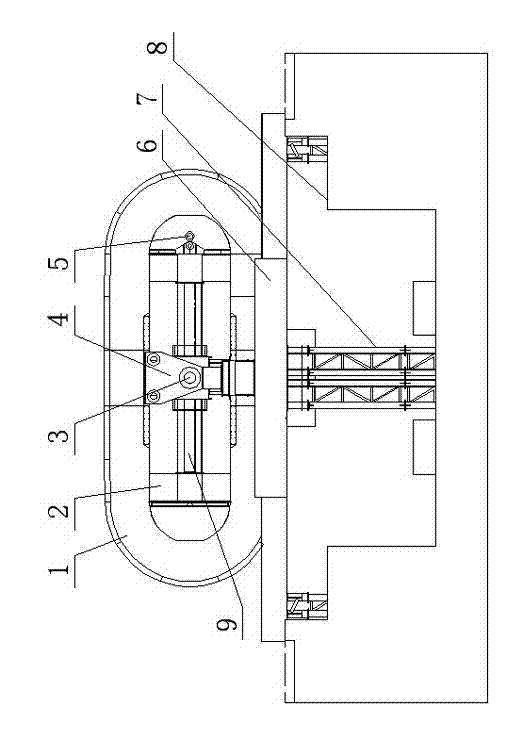

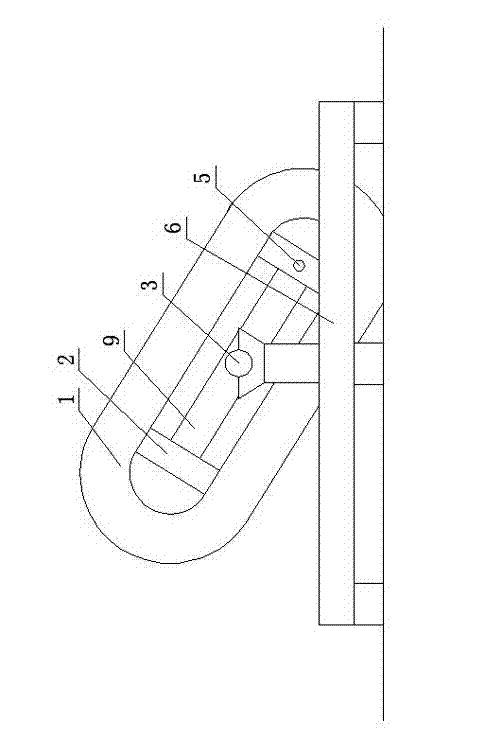

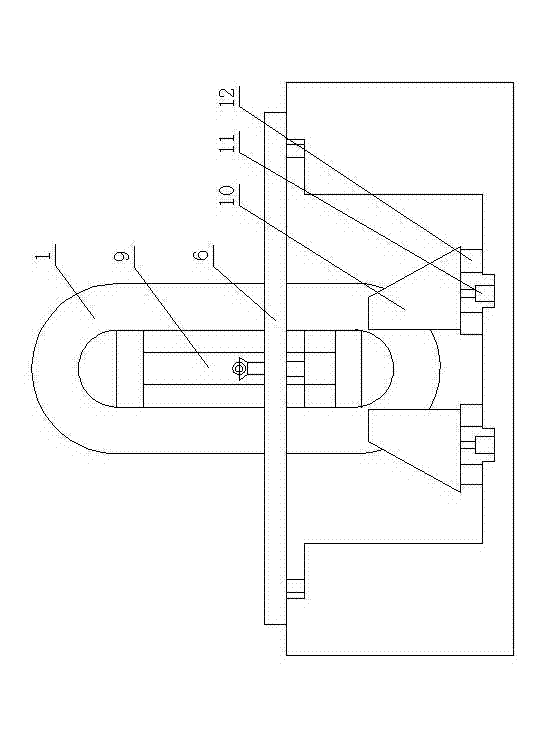

[0021] a. Set up the support column 7 inside the foundation pit 1, turn the assembled frame 1 onto the support column 7 with the cooperation of auxiliary parts and the flipping mold. The auxiliary parts are generally tools such as backing plates and jacks, and turn over the mold And the backing plate is a traditional arc structure. Frame 1 side stands on support column 7, as attached figure 1 location shown.

[0022] b. Install the overturn bracket 6 at the mouth of the foundation pit 1 and on both sides of the frame. The overturn bracket 6 is fixed with the rotating support 4. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com