Efficient and low-cost hollow-out method for sapphire wafer bar

A sapphire crystal and sapphire technology, applied in stone processing equipment, fine working devices, manufacturing tools, etc., can solve the problems such as the inability of the coolant to reach a large amount, the complex tool clamping mechanism, and the poor chip removal effect, and achieve good chip removal. Effectiveness, optimal balance of chip evacuation and corrosion protection, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of high-efficiency and low-cost sapphire wafer rod method of the present invention is mainly made up of following steps:

[0034] (1) Fix the sapphire crystal on the machine tool, open the cooling water pipe and continuously introduce the cooling liquid.

[0035] In the present invention, the machine tool is selected as a CNC drilling and milling machine, which can realize the programming control of the following steps through the CNC drilling and milling machine, so as to realize full automation, and the cost can be effectively reduced through this selection.

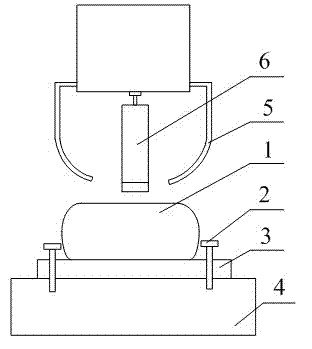

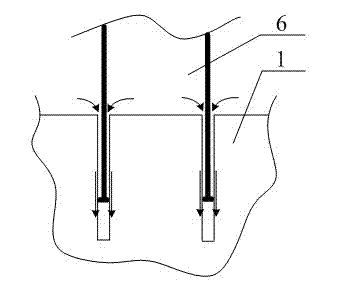

[0036] The specific process of this step is as follows: figure 1 As shown, the sapphire crystal 1 is fixed on the glass spacer 3 of the machine tool through the T-shaped bolt 2, and the glass spacer 3 is fixed on the machine tool table 4, thereby effectively fixing the sapphire crystal 1 on the machine tool. The cooling water pipe 5 is opened to allow the cooling liquid to flow out of the cooling water p...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 lies in that the rotating speeds of the cutters in each step are different. In the rod extraction step: the tool speed is adjusted to 300r / min; in the chip removal step: the tool speed is controlled at 500r / min, after 6s, the tool speed is adjusted to 300r / min.

[0047] In the pulling step of this embodiment: the depth of the rod is 2 mm; the concentration of the cooling liquid is 1.5%.

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 lies in that the rotating speeds of the cutters in each step are different. In the rod extraction step: the tool speed is adjusted to 500r / min; in the chip removal step: the tool speed is controlled at 1000r / min, after 3s, the tool speed is adjusted to 500r / min.

[0050] In the pulling step of this embodiment: the depth of the rod is 4mm; the concentration of the cooling liquid is 4.1%.

[0051] The rods of sapphire crystals can be pulled out through the above-mentioned embodiments, and the length of the rods pulled out can be greater than 250mm. At the same time, since the cutter diameter of the present invention ranges from 2 to 6 inches, the production of sapphire wafer rods with different diameters can be realized by replacing cutters with different diameters.

[0052] It is found by detection that the average production time of each sapphire wafer rod of the present invention is much less than the average pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com