Device and method for hydraulic forming of cavity part with complex curved surface

A complex curved surface and hydroforming technology, which is applied in the field of hydroforming devices for complex curved surface cavity parts, can solve problems such as wall thickness reduction, parts that are difficult to form, and slabs that are difficult to flow into the mold cavity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

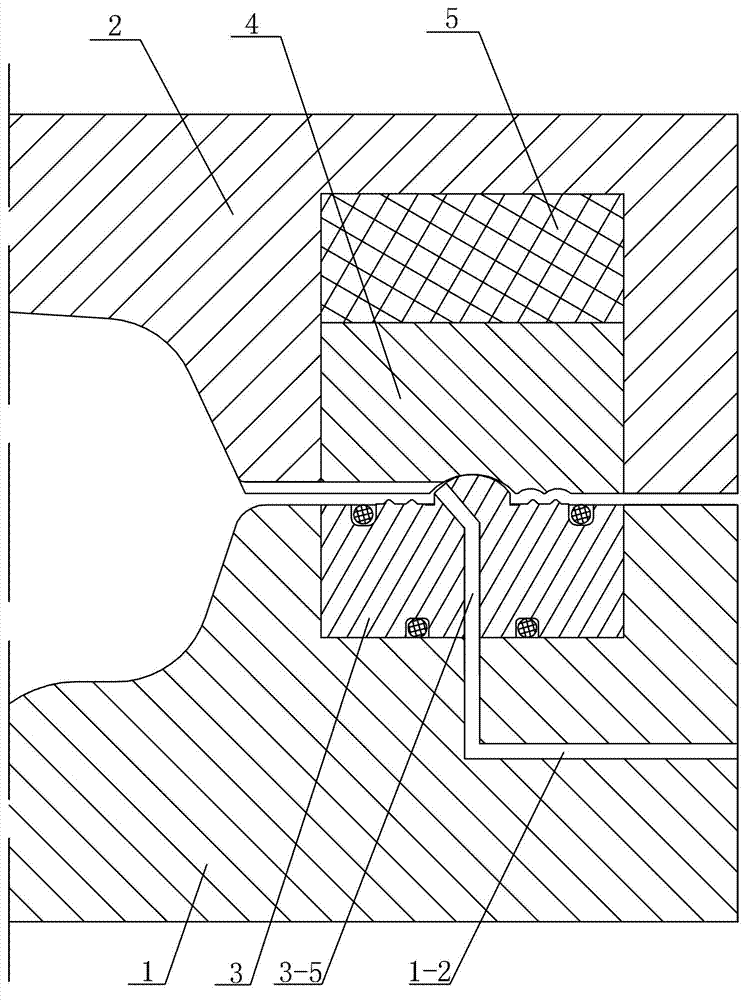

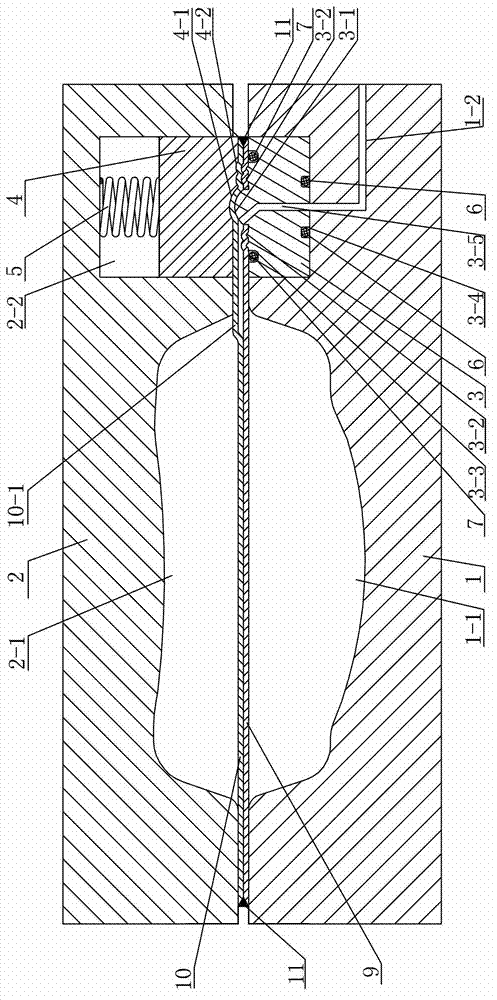

specific Embodiment approach 1

[0022] Specific implementation mode one: combine Figure 1-Figure 10This embodiment is described. The hydroforming device for complex curved cavity parts in this embodiment includes an upper die 2 and a lower die 1. The device also includes a lower liquid-filled insert 3, an upper liquid-filled insert 4, an elastic member 5, a second A sealing ring 6 and a second sealing ring 7, the lower end surface of the upper mold 2 has an upper cavity 2-1, the upper end surface of the lower mold 1 has a lower cavity 1-1, and the upper mold 2 and the lower mold 1 are completely closed The upper cavity 2-1 and the lower cavity 1-1 form the cavity 13 of the part to be formed, and an upper groove 2-2 is processed on the lower end surface of the upper mold 2 adjacent to the upper cavity 2-1, A lower groove 1-3 is processed on the upper end surface of the lower mold 1 at the position directly opposite to the upper groove 2-2, and the upper groove 2-2 is sequentially provided with an elastic mem...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 1 The present embodiment will be described. The elastic member 5 in the present embodiment is a spring. In this way, after the upper mold and the lower mold are closed, the spring can provide a pressing force between the upper liquid-filled insert and the lower liquid-filled insert, without being affected by the clamping force of the upper mold and the lower mold, and the liquid seal can be independent Control to meet the design requirements and forming needs. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 2 The present embodiment will be described. The elastic member 5 in the present embodiment is an elastic member made of polyurethane. In this way, after the upper mold and the lower mold are closed, the polyurethane can provide a pressing force between the upper liquid-filled insert and the lower liquid-filled insert without being affected by the clamping force of the upper mold and the lower mold, and the liquid seal can be independently Control to meet the design requirements and forming needs. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com